The NASA rovers Spirit and Opportunity on the planet Mars are each fitted with 39 drives made by the Swiss manufacturer maxon motor. Around one in three of the motors it produces are used in the medical technology industry. The small drives boast a whole array of special features, including efficiency levels of at least 90%.

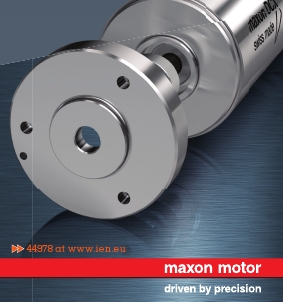

maxon’s RE 8 DC motor is 8 mm in diameter, 16 mm long and can deliver a nominal 0.5 Watts. It also weighs less than 4 grams. The motor shaft diameter is as thin as a pencil lead at only 0.8 mm and is made of high-tech ceramic material. Its electrical insulating properties allow for a compact commutator design.

High-performance ceramics

Technical ceramics open up new opportunities and offer benefits over steel and hard metal. These materials are lighter, more wear-resistant and have better anti-friction properties. Sleeve bearings with a high-performance ceramic shaft last longer than traditional ones.

Zirconium oxide (ZrO2,), which is used for shafts, has excellent dry run operating characteristics, good bending strength, is highly friction-resistant and can therefore be used in unfavourable conditions. Ceramics are also well suited for thermal decoupling, and do not produce any interference in inductive environments or heat up, thus opening up a wide range of applications.

Ceramic components can also perform well in the medical technology environment where conditions can be tough. The excellent anti-friction properties of this oxide ceramic material, coupled with wear-resistance, make it usable for sleeve bearings in precision technology. The manufacturer proved in its testing bays that ceramic shafts run in sintered sleeve bearings show a lower slip-stick effect than steel shafts. This can be crucial in applications where very precise and slow start-ups from standstill are required.

The service life of these bearings is longer than with a steel shaft. maxon has been working with a lubricant manufacturer to develop a special type of lubricant for ceramic materials that exhibits lower friction coefficients in a sintered sleeve bearing, even in mixed friction conditions. It is now possible to achieve an almost constant friction coefficient at very low speeds, whereas this was only possible to a limited extent before in systems that did not require hydrodynamic lubrication. This effect is put to good use in applications that operate frequently or constantly in mixed friction conditions. A 10 to 20 times longer service life is achieved in the drive sector where motors accelerate in 6 ms from standstill to 6,000 rpm. With such high acceleration, ball bearings exhibit a short slip phase on the races at start-up due to the inertia of the bearings, which, by experience, manifests itself as a troublesome noise. But in applications that do not achieve hydrodynamic operating status because of a rotating load, the ceramic shaft outperforms a steel one, as the sleeve bearing is not noticeably worn down due to zirconium oxide ceramic’s favourable surface.

Ironless rotor

The “heart” of the motor is the worldwide patented ironless rotor, System maxon. Compared to conventional DC motors, this motor principle has very specific advantages. In maxon DC motors, a proper copper winding rotates without armature iron cores. Mass inertia is particularly low thanks to the light-weight rotor, and acceleration is very fast. There is no magnetic detent whatsoever - a good characteristic for positioning drives, as the rotor stops in any chosen position. Electromagnetic interference is also almost negligible. There are six winding variations for motor type RE 8 which vary depending on the wire cross-section and number of windings. This means that there are different terminal resistances for the motor. As a result, the motor parameters specifying the conversion of electrical energy into mechanical energy (speed and torque constants) vary.

A sterilisable version of high-precision drives for speeds of up to 100,000 rpm

Sterilisable electromotors can now be used specifically for medical technology applications. They are quieter than compressed air turbines and the electric cables more flexible. maxon motor caters for a wide range of applications by offering three electronically commutated, autoclavable DC motors with diameters of 6, 16 and 22mm. Sterilisation in an autoclave is a good, quick and the most commonly used method of sterilising medical equipment, but it does place an extremely high load on drives and components, as they have to withstand the following ambient conditions: saturated water vapour of 134 °C at 2.3 bar repeated for at least 20 minutes. In the past, only sensorless motors were robust enough to cope with the extreme loads in an autoclave, but the addition of Hall sensors to motors means that a sterilisable version of highly dynamic servodrives can now be produced.

A grooveless stator can be used thanks to the patented maxon winding, making operation quiet and detent-free in a very wide speed range. The chosen winding layout means that high speeds can be achieved with relatively low voltages. These motors also fulfil all other requirements demanded of modern high-tech drives, i.e. long service life, easy to control, low electrical time constant, low inductance, overload capacity etc..

Together with a neodymium permanent magnet which is one of the best magnetic materials currently available, maxon’s ironless winding is very efficient, making this drive particularly suitable for independently-powered applications, such as lasers, levelling equipment or insulin pumps.

Medicine, surgery, laboratory, chemistry and medicine – from analysis systems to operation robots

Pumping, dispensing and mixing substances such as solvents, colours, blood, ointments and chemicals are common tasks in laboratory and medical technology that can all be rationalised and automated by using drives. Motors of all performance classes and sizes can be used. For example, micro pumps have to deliver precisely defined volumes with great accuracy and at a given speed, for which they require precision, speed and position-controlled drives.

In laboratory diagnostic analysis systems, samples are positioned in reagents with speed and high repetition accuracy by positioning drives using linear movements. Miniaturised pumps and feed lines have reduced the need for reagents and investigation material (such as blood), placing less of a burden on patients and the environment.

Short cycle times and quick displacement movements require the output shafts to exhibit great mechanical rigidity, such as micro-insulin pumps that administer the exact amount of insulin through the drive unit’s high positioning accuracy.

Other medical applications are endoscopic operation techniques, where mechanical, electronic and optical components are located in extremely small spaces.

Another example is eye surgery where the hollow shaft helps the gripper to light up the operating field or feed through the laser beam. One particular drive design involves the microkeratom, where two different speeds are available at the gearhead’s output end.

An automated therapy system supports leg movements on a treadmill of gait-impaired patients with neurological illnesses and injuries. As well as relieving the physical strain on therapists, it helps prolong training sessions and makes them more intensive, thus delivering better therapy outcomes. Drive units comprising a motor, brakes, gearing and a 4Q-servoamplifier are used for the hip movement and lift. The dynamics of maxon motors and the optimum volume/performance ratio are also critical in this application.

Special electronics in X-ray diagnostics

This project highlights the performance and competitiveness of maxon control electronics. The customer is one of the leading suppliers of angiography systems in X-ray diagnostics. These systems graphically display the human body’s blood vessels for investigating illnesses by means of an injected barium meal. A compact electronic unit is used to control and position 12 system axes. To do this, maxon’s development department, Electronics and System Technology, combined 12 EPOS positioning controllers on a motherboard, making installation and handling easy. Together with the electronics, customers can also obtain the motor-gearing-encoder combinations from the same supplier, providing them with a one-stop coordinated solution.

Drives in X-ray therapy

Modern radiation equipment delivers targeted, three-dimensional radiation of tumours without damaging nearby healthy organs. A so-called multileaf collimator that comprises over 100 motorised individually controllable fins helps distribute X-rays efficiently and in a precise dosage. However, it also means that over 100 drive units have to be located in an extremely small space – this requires small, compact, powerful and reliable motors and gearheads, but of course these are typical features of maxon drives. For this application, maxon supplies drive units of 13 mm or less in diameter.

Measure, register and record

Recording events immediately and reliably, documenting numerous measuring results accurately in a harsh environment – this is the task of chart recorders. Compact, highly dynamic and tough drives are called for in this instance. Space is often at a premium in these tools, as several drives and styles are usually involved. Paper feed speed can be a few cm/h as well as cm/sec, requiring drives to work smoothly without juddering, i.e. motors with linear gradients and minimal start-up voltage. Thanks to a low inertia rotor, any signals are played back without delay. The same level of quality must be maintained over a long period of time, often years. maxon DC motors with precious metal brushes are ideal for this task, as the low brush transfer resistance remains constant over the entire service life and guarantees very low start-up voltage. The legal provisions on electromagnetic interference signals are favourably guaranteed with CE certification of the drives. Complex and expensive noise filters are not required.

Author: Albert Bucheli, Head of Marketing Support, maxon motor, Sachseln, Switzerland