Safety concepts, safety integrity, machinery directive - The manufacturers of machines and plant, on the one hand and the suppliers of system components on the other are having to become more and more intensively concerned with the terminology and substance of machine safety. In the construction of safe plant the specification of safe system components is of great importance.

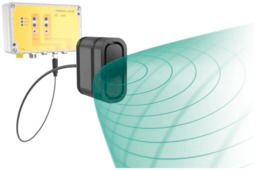

Sensors, such as safe rotary encoders, which stand right at the start of the information processing chain as quasi sense organs, are required to undertake an important function. Certificated rotary encoders with simple integration concepts not only render safety solutions easier to implement - they are also more economical.The industrial landscape is populated with ever faster operating high performance machines, in whose environment a whole range of robots and automatic feed systems are also operating in order to 'unload' the operating personnel. Anywhere, where such apparatus is operating and moving machinery parts are driven by high performance systems there is a potential for danger to the operating personnel and fundamentally a risk to human beings. In accordance with the machinery directive and the relevant safety regulations for personnel protection even brief lapses in attention must not lead to injury due to shearing, squeezing and impact, or worse. For the monitoring of rotating or swiveling components preferably rotary encoders are used in the drive systems and these thus represent a central component when considering the safety of the drives.

IEC 61508: New pilot standard for functional safety

In order to keep the expense of safety measures within limits, rational safety concepts will increase in importance in the future. Consequently, in this context the functional safety of individual system components, such as rotary encoders, assumes new significance. This transpires against the background of a changing situation with regard to standards, since the standard EN 954-1, which has been binding since 1996, remains valid only up to the end of 2009 in the context of a period of transition.

The deterministic approach of EN 954-1, of countering the deduced risk categories by means of an appropriate system behavior, will now be superseded by the more effective standards EN ISO 13849-1 and EN 62061. With their consideration of failure probabilities (probabilistic approach) these are also more in keeping with the requirements of modern programmable electronics, which has for long been subject to the considerations of safety technology. IEC 61508 serves as a higher-level pilot standard on functional safety. Although in the transitional phase certification to EN 954-1 remains adequate, as the expiry date approaches machine constructors and suppliers will have to become better acquainted and in accord with the new standards.

Optimized architecture reduces expense

Since the architecture determines a significant proportion of the costs, clever ideas can reduce these costs and at the same time increase the efficiency of the sensor-side system safety. The use of mechanisms featuring two-channel operation, without completely duplicated execution of the functional units, is an effective approach here. Of course, systems with two rotary encoders or a dual encoder will not necessarily have to be classified in accordance with the new standard. In order to achieve a high safety evaluation for a sensor, it must be ascertained that the proportion of non-dangerous failures (SFF - Safe Failure Fraction) is correspondingly high. Pepperl+Fuchs Drehgeber, Tuttlingen, is currently developing a new safety concept for rotary encoders, in which such mechanisms are being considered. This includes, for example, self-diagnosis, with which faults can be detected extremely efficiently. Self-diagnosis implies that the device is able to detect its own fault conditions and then to reliably communicate the same. In this way machines and control systems are able to immediately carry out a defined stoppage, before any subsequent failures can lead to a dangerous situation.

Users favor simple integration

In order to ease and hasten the transition by machine constructors to the safety requirements of the new standards a simple integration of the components is necessary, even in existing developments. The new safety concept offers both technical noveltyin the architecture and a simple interface for the user, which is provided without additional cables, interface cards and safety modules. The use of existing standard components, functions and existing communication paths are the key to this simple integration.

A step worth taking

In view of the increasing level of automation in the applications involved in machinery and plant construction, plant manufacturers, system integrators and suppliers are also obliged to increase their safety functionality. Concrete framework conditions create new, extended safety standards, which take into account the requirements of modern electronic safety systems. Against this background safe rotary encoders with functional safety take on new significance. An improvement in safety for conventional control systems and total compliance with all the requirements of the safety functions of modern drive controls are required. In response to these needs, Pepperl+Fuchs GmbH has developed a range of certificated rotary encoders that incorporate innovative concepts to enable economical system integration. New ideas make the system easier to use with existing communication channels and allow it to be used in high safety category systems up to SIL3 (in accordance with IEC 61508).