We interviewed Frank Hakemeyer, Director Communication Interface at Phoenix Contact Electronics. He believes that the latest 5G approach could overcome current communication challenges and become the backbone of industrial automation.

IEN Europe: Which are the advantages of this 5G router?

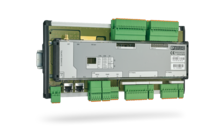

F. Hakemeyer: It’s the first, or one of the first industrial 5G devices on the market. It offers 5G communication according to release 15 of the 3GPP specification series. And it supports NSA (non-stand-alone) and SA (standalone) networks. Our router can be used for connecting ethernet devices such as PLCs, gateways, or IPCs via a private 5G network to the plant infrastructure. It can also be used by using VPN technologies to build up communication links through a 5G public network and the internet to enable secure communication between several industrial locations or applications. And it has been tested in the Ericsson labs to demonstrate 5G communication already.

IEN Europe: How did your collaboration with Ericsson and Quectel start? Are you planning to further expand this partnership?

F. Hakemeyer: Phoenix Contact and Ericsson have initiated together with some other OT and ICT companies the 5G-ACIA (5G alliance for connected industries and automation - www.5G-ACIA.org). It is an alliance of OT and ICT companies, together with some research institutes and providers.Based on this activity Phoenix Contact and Ericsson extended their part- nership in developing and testing the first industrial 5G router. Quectel has joined that project to contribute with their first 5G radio module in sub 6GHz. It was a very fruitful collaboration that combined the strengths of three totally different partners within one project. Of course, the good experiences made within this project are being continued.

IEN Europe: Which kind of contribution did Phoenix Contact bring to this new solution? And why are private 5G networks important in an industrial setting?

F. Hakemeyer: Phoenix Contact has a long term experience in license free wireless solutions based e.g. on Bluetooth, Wifi, or Trusted Wireless and on licensed wireless solutions based on cellular technology e.g. 2G, 3G, or 4G. Almost 20 years now we´re offering our customers wireless products and solutions and we can create the right technical solution for the individual use case. So, from our experience we can clearly say that license free wireless solutions mainly suffer from three main challenges:

1) No guaranteed quality of service - due to the nature of using a license free frequency band, you can never manage and guarantee the communication. It´s always a “best effort” approach. Medium Access Mechanisms like “listen before talk” allow all users of the license free band an equal access and an equal degradation of service in case of congestion of the band. In cellular networks the frequency bands are licensed to operators, or in private networks to plant or factory owners.

2) In license free wireless solutions there is no single technology that is capable for all use cases. You need to select the technology according to the requirements of the use case. In the end you have a heterogenous world of technologies and products which are difficult to combine and challenging to manage (coexistence!) at a single location. In a 5G network the management of resources, the orchestration of all applications and the prioritization of use cases is a characteristic of the architecture of the cellular technology (e.g. scheduler etc.).

3) There were some activities to develop even industrial specific, license free wireless solutions e.g. WirelessHart, or some proprietary technologies such as Trusted Wireless from Phoenix Contact. The solutions are good and can solve industrial applications in a very good manner. However, they will never become a mainstream technology such as cellular based communication. In the end the amount of engineering effort, optimization and cost reduction is not comparable to a mainstream technology. On the other hand, one could have used licensed wireless solutions i.e. cellular 2G, 3G, or 4G technology. But those technologies are suffering from these three main challenges:

1) From 2G to 3G to 4G nearly the only focus was made to more data throughput. From kBit/s to MBit/s up to hundreds of MBit/s. But there were no measurements taken to improve reliability, or quality of service (QoS) or short latency communication. So, until 5G the focus was purely on commercial communication via smart phones and tablets.

2) The frequencies in the countries were auctioned to the MNOs (mobile network operators). The MNOs designed their offer around commercial, non-industrial use cases. With the start of IoT first business models came up that were not b2c but b2b. However, the networks of the MNOs were not addressing any needs of the industrial world so far.

3) The public cellular networks are made for consumers. There is almost no transparency of what is going on in such a network. A consumer just sees three bars on his cell phone that indicates the strength of the radio signal – that´s all the diagnostic available. This is not enough for industrial usage. In addition, there is no service guaranteed so far. In the past using cellular networks for industrial applications was just for uncritical applications, such as monitoring or maintenance. So, you can see, the 5G approach – especially with new enhancements (private 5G networks, network slicing, ultra-reliable low latency communication, etc.) can overcome challenges from the license free world and improve the “old” public networks which were only designed for commercial applications. 5G private networks can become a new communication backbone for industrial automation.

IEN Europe: Who will benefit from this 5G router the most?

F. Hakemeyer: We can see some plant or factory owners who are the “early birds” in the usage of 5G in industrial applications. These companies can use our 5G router to learn about the new technology. How it is used, how it is managed and what it can offer. By using our 5G router these companies can make their first own experiences – hopefully in a private, local 5G SA network.

IEN Europe: How much time do we have to wait in your opinion for a full implementation of 5G in the industrial setting?

F. Hakemeyer: End of 2018 Rel. 15 was published including the New Radio (NR) specifications and first time 5G related features. In June 2020 release 16 was completed by 3GPP and now we need to wait on release 17 (expected end of 2021). To get a “full” 5G feature-set we need to wait on release 17 (expected end of 2021). Of course, chipsets, radio modules and then devices are always coming in sequence after publication of the 3GPP specifications. I expect a full 5G feature-set of an industrial router maybe end of 2022 or beginning of 2023. However, release 18 with more industrial automation relevant topics is already under discussion. So, you can see there will be no final date when 5G is done. 5G will be a journey, not a destination.

Sara Ibrahim