The UI-5260FA model with Sony IMX249 2.3 MP CMOS sensor provides the standard image formats 4:3 and 16:9. At full resolution of 1936 x 1216 pixels, it delivers 47 fps, fully utilizing the GigE bandwidth. With its exceptionally high dynamic range and outstanding signal/noise ratio, it ensures high-contrast and practically noise-free images, which are impressive even in weak or fluctuating lighting conditions.

With its 2/3" Global Shutter IMX264 CMOS sensor (5 MP), the UI-5280FA meets the very toughest requirements in terms of light sensitivity and dynamics, while simultaneously achieving very low dark noise. The high NIR sensitivity makes the invisible visible to the human eye and renders a special NIR sensor version obsolete. It delivers images in 4:3 format with a frame rate of 23 fps.

IDS will be launching two more camera models soon: the UI-5270FA with IMX265 sensor (2045 x 1542, 36 fps) – currently the best CMOS image sensor in the 3 MP class – and the UI-5290FA with IMX267 sensor offering a resolution of 8.9 MP (4112 x 2176); this camera performs impressively in slower machine vision applications that require a large field of view.

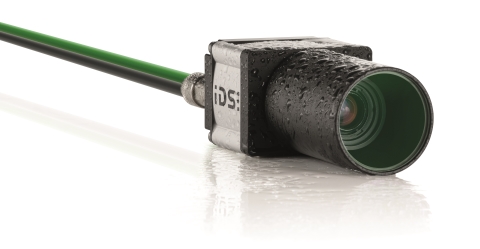

The GigE uEye FA cameras are all available with a choice of the established IDS Software Suite or, in future, GigE Vision firmware.

Learn more about the GigE uEye cameras series