IEN: Mr Kübler, your company celebrates its 50th anniversary this year. What have been the most important factors of success?

LK: Clearly the 320 people working for our company. Why? Because in the past few years, our team has learned to adapt itself more rapidly to changes, avoid making mistakes or foresee market trends to a certain extent. Our team shows a tremendous commitment and continuously provides highly innovative stimuli. This special mix has proved to be one of the major strategic factors for success. Secondly, we lay great emphasis on long and intensive relationships with our customers, which results in the fact that we know well in advance which solutions they will need in the future. I’m absolutely convinced that our growth is mainly based on this factor. Our customers get innovative solutions, as well as reliable service from Kübler, and they could experience this special corporate culture during our anniversary celebration in July this year.

IEN: What have been the product milestones in the past 50 years?

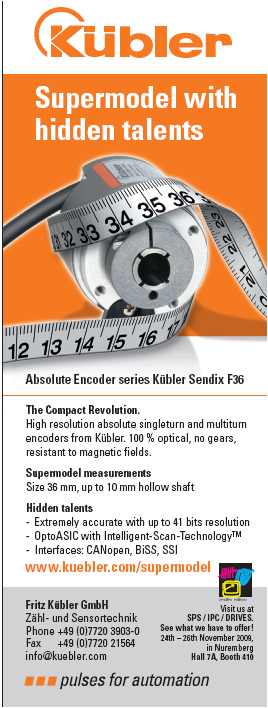

GK: One of the first milestones was without any doubt already laid out by our father in the very first year of this company. In 1960, Fritz Kübler Precision Engineering launched a patented short time meter with a permanent time display. Shortly after that, my father built the first electromechanical counters, for example preselection counter with the „unbelievable“ counting speed of 100 Hz. The electronic counters were another technical innovation in 1975. In the mid 80s, the company had great success with its miniature counters. Thanks to ever new, patent-protected models, we became the market and quality leader. With the Codix series, we have been able to strengthen our position in the past ten years in the field of electronic counters and process devices. In 1989, we started developing the first path sensors and encoders. Initially, this step was a rather arduous one, but it contributed greatly to our success story, especiallly in the last 15 years, where we opened a very special chapter in 2005 by launching our Sendix encoder family. For our most recent innovation, the miniature multiturn encoder Sendix F36, we received the prestigious Mousetrap Award in the US, and in Germany we ranked No. 1 at the Sensor Messtech Award. The jury was impressed by the optical Intelligent Scan Technology of the 36mm small encoder, which enables a highly precise rotational position sensing with feedback in real time.

IEN: Together with your brother Gebhard, you have been in charge of this company since 1997. How does the division of work look like between the two of you?

LK: We do have a division of responsibilities, which however is flexible enough to meet new requirements and tasks. Whereas my brother Gebhard’s main areas of responsibility are on domestic sales, marketing, human resource planning, purchasing and production, my focus is on export, R & D, finance and IT. As we both maintain close customer contacts, we communicate the „customer’s opinion“ into the company together. This way, the Kübler group is always customer-oriented, while our individual experiences complement each other in a positive way.

IEN: After a 17 percent decrease in revenue in 2009, you were able to increase your sales significantly this year. What are your expectations for 2011?

LK: Just to give you a brief overview: In the past ten years we have been able to increase our revenue from roughly 12 million Euros to almost 40 million Euros. 2010 plays an important role, as we expect an increase by 40 percent, which would be unprecedented. For us, there are two reasons for this development: One is that the demand in general is increasing, the other is the fact that we were able to acquire some new key accounts. Overall we have increased our market share, which will result in an extension of our capacities. We already have increased our staff by 10 percent this year. To maintain our aim of high delivery reliability, we are also investing considerably in logistics. We even increased our stock on a short term, in order to profit from short delivery times, as we too had problems with that in the second and third quarter this year. For 2011 we also expect a double-digit growth, with increases in all three business units.

IEN: The Kübler group is subdivided into three main business units: sensor technology, counting and process technology, and transmission technology. Where is your current focus in terms of industrial branches, and in which branches would you like to get a stronger market share in the near future?

GK: Our products go into many different branches. For some branches however Kübler has developed special solutions in the past few years. We have employed highly specialized branch managers, and thus earned considerable market share in those areas. Within sensor technology, drive technology (with focus on gear motors), solutions for elevators and wind turbines are among those areas. The energy meter market is an example for the counting technology. Most recently, there are new branches like Mobile Automation and the steel industry that play an important role. In the OPS business unit (OEM Products and Systems) we are able to realize more extensive systems or OEM solutions. One example: We supply a major manufacturer of spark-erosion machines with a combination of DC drive and encoder, including mounting material. For this we cooperate with certified partners. We take the overall responsibility for the project, and as a consequence the customer gets everything from one source.

IEN: At a press conference for the 50th anniversary celebration you named the Kaizen culture as one of the core factors for your success. What does Kaizen mean, what positive aspects does this culture have on Kübler, and what are the benefits for your customers?

GK: Kaizen was originally established by Toyota and has as its core value the continuous strive for perfection. It is a continuous task in which all employees are involved. Where can we avoid waste, or how can we increase quality and flexibility? Those are the typical questions. At first we had to establish certain structures within our company – with tasks, competences, responsibilities and authorities. It was only then that we started to implement certain quality assurance tools and proceedings. The benefit for our customers is that quality and reliability are ever increasing. For all this we established a full-time Kaizen office two years ago. Today we speek of a Kübler Kaizen culture, even though despite some good success we’re still at the beginning of this process. The more we learn, the more we realize what actually has to be improved.

IEN: What are the most recent innovations in your product portfolio?

LK: There are new members in our Sendix encoder family, since now Profinet interfaces are incorporated in the multiturn and singleturn fieldbus encoders. Those encoders support the Isochronous Real-Time-Mode, which is also called IRT-Mode, and are thus ideal for real time applications. With another new product we approach heavy industry applications, especially for huge cranes and the steel industry. The new family of incremental heavy duty encoders has a completely new design and is very easily installed. In the field of process technology we have a new generation of Codix displays and controllers. Those products are also easily handled and programmed. The basic idea was to develop a device where the user can leave the user’s manual in the locker.

IEN: Mr Kübler, how is your forecast for the next 50 years?

GK: Of course it is not possible to give a detailed forecast for such a long time span, but one thing for me is set in stone: technology will even have a greater impact on the Kübler group than ever. Within the next decades we will try out different business models and implement some of them successfully. By doing so we will conquer new markets and tap new revenue resources apart from mere product sales. We focus on constant growth, and we are quite confident to at least keep the pace of the past ten years. To be more precise, this means tripling our revenue by doubling our staff until 2020. In figures: 100 million Euro revenue and 600 employees.

IEN: Gentlemen, thank you very much for the interview.

Gebhard and Lothar Kübler were interviewed by Jürgen Wirtz, Editor IEN Europe.

Facts & Figures

Owner: Kübler family

Employees: 320 worldwide

Expected Revenue 2010: 39 million Euros in the group

Headquarters: Villingen-Schwenningen, Germany

Presence: Six subsidiaries worldwide and more than 50 representations Production: Villingen-Schwenningen and Munich, Germany, Pune, India

Main Product Lines: Products in sensor, counting and process, transmission technology, as well as system solutions