Sensata Technologies. A single factory can lose $2.3M annually due to unplanned stoppages. In some industries – such as automotive – those costs are even higher, with losses of tens of thousands of dollars per minute of unplanned downtime.

In the current environment, those issues are also being magnified by the hiring and labor shortages many companies are facing today. Data from the Chamber of Commerce found that 35 percent of all openings in durable goods manufacturing were unfilled at the end of 2021.

In addition to their issues filling open headcount positions, many of those same companies will soon be facing waves of retirements from their more experienced workers. Almost 25 percent of the U.S. manufacturing workforce is over the age of 55, and by 2030, there could be up to 2.1 million unfilled jobs in the sector due to a growing skills gap.

On several fronts, plant managers are being asked to do more with less.

Legacy Maintenance Approaches Create Stubborn, Inefficient Processes

With some exceptions, current and legacy machine health maintenance strategies continue to be driven by manual walkarounds and standard preventative maintenance schedules. Walkarounds will continue to be a mainstay in most facilities, and it remains valuable for maintenance personnel to directly review machine assets on a regular basis.

However, relying on them as the sole method of fault detection is both an inefficient use of resources and a source of unnecessary risk. As experienced workers retire in the coming years, their less experienced replacements will need additional support to deliver the same level of asset performance.

Standard time-based preventative maintenance strategies also have their limitations. If those processes are followed appropriately – and resourced appropriately - they ensure lubrication, etc. measures are completed in a regular manner.

However, it is also a costly and time-intensive process, taking up the resources of the maintenance team – often when no issues are present – while also introducing additional opportunities where human error may result in negative consequences for the asset itself.

Over the long-term, many plant operators will be under continued pressure to move away from traditional PM schedules and either extend maintenance timelines – when not limited by warranty terms – or find alternative approaches.

Connected Devices and IoT Gaining Momentum

Predictive maintenance and the Industrial Internet of Things (or IIoT) are concepts which have been building in the industry for years, but have finally reached a point of maturity where solutions are becoming more and more accessible.

Looking at the industry holistically, the predictive maintenance market stood at $5.6B at the end of 2020, representing a 17% jump year-over-year.

While impressive, it represents just the starting point. Survey data found that less than 40 percent of companies have invested in predictive maintenance, but within the next 3 years more than 75 percent expect to have projects in motion.

Even at companies where smart sensors and other IIoT strategies are in place, the cost structures associated with those platforms mean that only 15 percent of assets are currently monitored by connected devices. In an integrated building or factory setting, a production line is only as resilient as its least reliable asset.

As solutions become more affordable and return-on-investment evaluations shift, growth in IIoT is expected to scale rapidly. From 2021 to 2026, the industry will nearly double its acceleration, with a forecast compound annual growth rate of 31 percent through 2026.

As the share of assets being monitored by smart sensors in real time set to grow, plant managers can use that data to rethink how those assets are maintained on an ongoing basis.

Connected Assets Drive Condition-Based and Predictive Maintenance Approaches

The growth of IIoT-based solutions is unleashing for a paradigm shift in machine health monitoring – allowing companies to gently shift away from manual walkarounds and legacy PM schedules and toward condition-based or predictive asset monitoring approaches.

Condition-based systems are built around a sensor – such as a vibration, pressure, or temperature sensor – connected to a monitoring platform via either a wired or wireless connection.

Based on the machinery and processes in place, an alarm or alert value is set which would represent an error state or potential machine health issue. If the alarm is triggered, technicians are alerted, and the team works to identify the issue, and replace the machine or part.

One straightforward example may be the concept of using temperature sensors to monitor high-resistance joints in a motor, where loose or corroded electrical connections can generate current arcing, a rise in temperature and a potential fire. When the temperature reading reaches a critical value – signifying an issue where motors may be nearing a failure point – the maintenance team is alerted and can schedule corrective action appropriately.

Predictive maintenance takes the principals of condition-based maintenance and pushes them further – using machine learning/artificial intelligence to identify issues earlier, proposing what maintenance steps may be helpful in rectifying them, and create a better overall picture of machine health.

Rather than waiting for issues to reach a critical alert value, the system looks for anomalies in various sensing modalities and uses those values in combination with machine learning/AI algorithms to predict upcoming machine failure and identify the root causes of potential issues. This kind of automated fault characterization can also reduce the need for companies to have a vibration analysis expert on-hand.

This dynamic is often represented using the P-F (Potential Failure – Functional Failure) curve, where the system can interpret different sensor readings and make judgements about the remaining useful life of the asset.

This type of evaluation can allow operators to determine the amount of time they have to make repairs and identify the optimal time to take corrective action – creating a minimum amount of disruption to overall operations.

Vibration monitoring specifically can create a strong return-on-investment for a wide variety of assets, as its principles can be widely applied to a motors, pumps, and other rotary equipment assets. Over 50% of motor failures are due to premature bearing failures. In addition, many of the rotating machine faults that can be diagnosed with vibration condition monitoring - such as unbalance, misalignment, and mechanical looseness - directly impact the motor’s bearings.

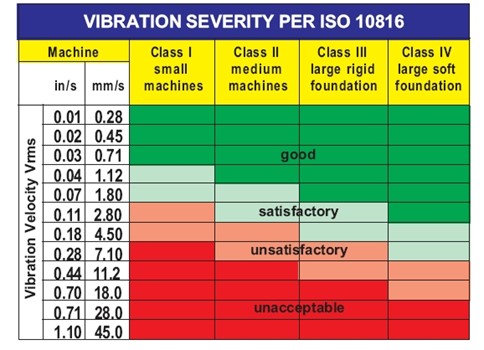

Vibration analysis also ties in directly to the ISO 20816 standard (which replaced the previously existing 10816 standard), which establishes how companies should evaluate machine vibration magnitude and shifts to help ensure reliable operation of the equipment.

In most cases, vibration begins far earlier on the P-F curve than audible noise or temperature variations that can be detected during a standard operator walkaround.

By using vibration analysis in combination with other sensor types, operators can identify potential machine health issues earlier in the process and approach corrective action on those assets with a long-term view. Repairs do not need to take place immediately, but can be scheduled for the optimal time within the expected useful life of the asset.

This type of predictive insight also creates additional benefits from a supply chain and balance sheet perspective, as plant managers can optimize their near- and medium-term parts requirements and may be able keep fewer parts on-hand on a regular basis.

Digital Transformation for Smart Factories and Buildings

As these connected solutions continue to transform maintenance approaches, plant managers and other corporate leaders will need to remain flexible as the idea of smart buildings and factories continues to mature.

Solutions likely to deliver the best near-term gains will likely be iterative solutions which can be retrofit onto existing motors and other assets, with true “connected” options from many OEMs still in various aspects of the product development phase.

But as each asset comes online, the maintenance processes around it will shift from reactive break-fix solutions toward predictive, smart approaches that prioritize the right actions at the right time. That will allow maintenance personnel to put down their clipboards and focus on performing the tasks that improve machine health, reduce downtime, and drive down costs across the organization.

Paul Heine, MBA, PMP, SP, IIOT Product Manager, Sensata Technologies