SPETEC Cleanroom technology is used in the manufacture, packaging and storage of dust-sensitive mechanical and electronic components and wherever a particle-free environment is needed.

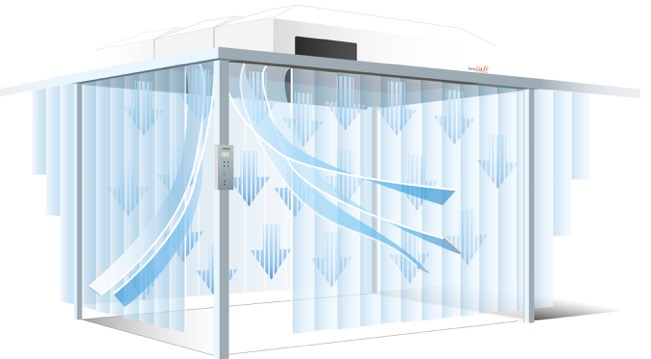

A complete cleanroom workstation can be installed in the cleanroom cell. SPETEC offers different cleanroom concepts up to 350 m². The cleanroom cell consists of anodized aluminum profile sections and can be set up in any laboratory, production room or hall without the need for any special construction work.

The effective cleanroom area can be varied by combining individual laminar flow modules of different sizes like SPETECs FMS Laminar Flow Module “SuSi”.

The name SuSi comes from "super silent". It is possible to equip a workplace with clean room facilities simply, cost-efficiently and with low noise emissions. The module is fitted directly above various types of workplaces or over a machine. The Spetec cleanroom devices are equipped with a filter of the type H 14.

Visit us at Hannover Messe 2019, Hall 16 Booth D41!