Projects of the European Space Agency, or ESA, and those of its North American counterpart, NASA, run into billions of Euros. In these kinds of dimensions, the aspect of safety is hugely important because every single mistake or wrong movement by astronauts can have health consequences and be very expensive. At a first glance, it is astonishing that inexpensive profile dampers such as those from ACE's TUBUS series are capable of supporting ESA and NASA missions. If we take a closer look, we can see that slowing down forces play an important role - even in zero gravity.

More effective training at a lower cost. The British Qinetiq Group plc lays claim to this statement. The leading Belgian company for the integration of space systems has belonged to the Qinetiq space segment since 2005 with Verhaert Space in Kruibeke. Its customers include the ESA and other renowned organisations such as NASA alongside the British Ministry of Defence. Clients like these need high-end solutions. This is the specialist area of the Belgian subsidiary's team with the most extensive technical knowledge. The solutions are determined by extreme versatility and spirit of innovation. Constructing a specialised treadmill for astronauts is therefore one of Qinetiq Space's projects due to its special accessories.

Running is nothing unusual. The opposite is in fact true: it is, in itself, one of easiest activities a person can do. However, it is not possible to run in zero gravity without the use of aids. Once your feet have left the ground, you literally don't have a grip anymore. Astronauts are therefore linked to rigid moulded parts to exercise on treadmills on spaceships and space stations. With regular, intensive training, the negative impacts of zero gravity on the astronaut's muscles and bones are minimised so that they do not experience any health problems when they return to earth after long periods in space. Due to the fact that astronauts described being attached to very inflexible rubber as being uncomfortable in test series, Qinetiq Space was awarded the assignment to develop a new generation of treadmills. The space travel specialists had a model based on bungee ropes in mind, so that the exercising person is practically kept on the ground by his or her own weight.

Space travellers put new treadmill through its paces in zero gravity

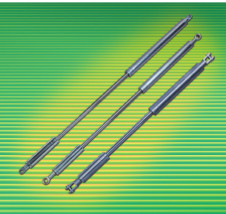

The Belgian astronaut Frank de Winne spent six months on the ISS space station in 2010. He was very familiar with the conditions on the treadmills used up until now. This was one reason why the Qinetiq Group plc's Belgian subsidiary selected him as a test person. The other reason was that zero gravity is not easy to simulate on earth. Frank de Winne had to climb aboard an aircraft. And not just any aircraft, but an Airbus A300 converted for special flights called the ZERO G. Numerous tests were performed with it. The team completed 31 so-called parabolic flights per day for a whole week. Zero gravity is produced for 22 seconds in this method of flying named after the parabola shape. The whole parabolic flight process takes two minutes in which the test person's body has to repeatedly withstand up to 2 G, therefore double gravity. This constant change can lead to sickness in mere mortals. However, an astronaut has the experience to be able to train under these conditions and provide valuable test results. After all, the second generation of treadmill called T2-Rack should soon be used on the ISS. Frank de Winne wore a harness attached to the treadmill with bungees for training. The TUBUS series dampers serve the purpose of securing the whole system. Three of these profile dampers from ACE, which are used as an alternative to industrial shock absorbers when on-the-spot stopping is not important, are used here. One TUBUS is in the pneumatic cylinder and the other two are positioned in the rest of the system. All dampers have the task of protecting the system if the drive belts for the treadmill are damaged. If this were the case, the cylinder would reach a very high speed and be severely damaged at the end of the stroke. The other two dampers protect other mechanical parts of the drive.

Dampers tested and found to be good

Before the TS32-16 type TUBUS were mounted on the treadmill, they had to convince the construction engineers from Qinetiq Space bv in Kruibeke and then the ESA and NASA of their efficiency. Tests were performed with a special high-speed camera and the impacts on the profile dampers recorded. The camera found out that the dampers only need 5.5 ms to slow down the force over a path of 12 mm under the maximum load of 18.75 Nm. This means that the construction engineers, and subsequently space travellers, have more than sufficient reserves for any unforeseen worst case scenarios. According to information from the company ACE from Langenfeld in Rhineland, these machine elements made of co-polyester-elastomer are capable of absorbing up to 26 Nm per stroke.

Linear effect TUBUS models were used in the case described here. They can also be supplied as degressive or progressive effect models for other constructions. Due to their space-saving design, they are attached in the actual pneumatic cylinders, which is an obligatory criterium for the function already described. With authorised temperature ranges of -40° C to 90° C, the TUBUS series is perfectly suited to indoor use in space and outdoor use on our own home planet. They are equipped for almost all environments on earth with their resistance to greases, oils, microbes, chemicals and sea water.