IEN Europe: Can you provide us with an overview of Resolve Optics' experience and expertise in designing optics for military applications?

Rob Watkinson: Producing a rugged lens optimised for military applications is a demanding task. However, drawing upon over 20 years of experience, our team of optical and mechanical engineers and designers have a proven track record in producing high quality military fixed focus and zoom lenses. Numerous customers have found sourcing a ‘designed for purpose’ lens from Resolve Optics has resulted in shorter lead time, lower cost, and a better overall product for their target military application.

What are the key challenges of designing optics for military applications?

Designing and producing a lens or optical system for military use requires careful consideration of its resistance to vibration, shock, temperature, and water ingress to ensure high reliability and top performance.

For defence applications – the environmental demands can be much higher than for a typical commercial product. Our designed for purpose lenses have much higher life expectancy than regular commercial grade lenses would provide when exposed to the same demanding conditions.

To ensure lenses meet military grade specifications, requires that all environmental demands are not only carefully considered during the design phase but that they are also then qualified with physical testing.

Can you share with us some examples of Resolve Optics lenses and optical systems that are being used in military applications?

Most of our military customer applications are covered by non-disclosure agreements making it impossible to discuss specifics. However, speaking generically, I can tell you that we have supplied many Head-up Display (HUD) lenses into the military market. These lenses sit in the cockpit of an aircraft and record the pilots view at the same time as capturing the graphics from there head up display. The challenge we had when designing a lens for this application was that each different aircraft would require a slightly different field of view. To produce a different fixed focus HUD lens for each type of plane would be an expensive solution. Consequently, we produced a novel zoom lens design that would cover all the required field of views. This enabled our HUD optics to be mounted in fixed positions to provide the correct FOV for almost any aircraft. This unique approach has enabled us to achieve economy of scale on a vast majority of the components in our HUD lens and therefore provide our customers with a much more cost-effective solution.

What benefits do your custom designed lenses offer to military product designers when an off-the-shelf optical component may be cheaper?

Because off-the-shelf lenses are typically produced in larger quantities than designed for purpose lenses they typically will be cheaper. However, the chances of you finding an off-the-shelf lens that meets all your operational and performance needs are often slim. For example, you may find a lens that suits your optical requirements but is not designed to withstand the environmental specifications or available space. Perhaps a specific custom mount is required. This is where you will see the benefit of a designed for purpose custom lens. When sourcing a designed for purpose custom lens, all considerations are considered from the design stage with an aim to provide a lens that meets all of your requirements without needing to make significant compromises. Another big advantage of a custom lens is security of supply. As you may be only one of a group of customers for an off-the-shelf lens you have little control over a manufacturer choosing to discontinue a critical optical component for your product. This will never happen with one of our custom lenses. As long as the customer keeps placing orders, we will keep supplying.

Can you describe the steps involved in the design process for military optics, from concept to production?

The design process for military optics typically starts with the contractor supplying us with a specification for their ideal lens. After reviewing this specification, and determining its feasibility, we then put forward a proposal for what we feel is the best solution for their application. Although we aim to produce a design that will cover every single one of the requirements, sometime the laws of physics will get in the way and non ‘mission critical’ compromises will have to be made. For this reason, regular communication with the customer is vital to ensure everything is clearly understood by all parties involved. Our aim is to provide a designed for purpose lens proposal within 1-2 weeks of receiving the initial enquiry. Once a final optomechanical design and operational specification is agreed upon, and an order placed, we move forward and finalise the design before proceeding to manufacture. The time scale for this can vary massively depending on the complexity of the design but for a relatively simple fixed focus lens would typically take around 5-6 months from point of order to delivery of the first lenses.

To maintain a high-quality image when deployed in a battlefield environment what challenges must a lens or optical system overcome?

Again, our main concern here is that our lens can withstand the levels of vibration and shock that it may be exposed to. Without due care in the design of such lenses, the glass elements are likely to move which can severely affect its optical performance or even result in catastrophic failure. In most military scenario – high reliability and maintenance of optical performance are critical.

Robustness and reliability are very important to optical products that operate in a military environment. What testing facilities does Resolve Optics have to prove the suitability of its lenses and optical systems prior to deployment?

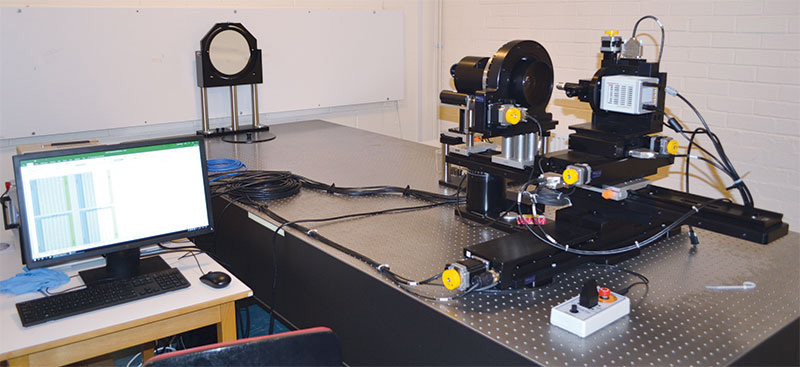

Resolve Optics has its own in-house testing facility for vibration and shock which allows us to provide ISO qualification for any of the lenses we produce. This vibration test facility enables us to not only qualify optics and optical assemblies with all the common forms of vibration testing, but also undertake specialist vibration/shock qualification tests in accordance with customer requirements.

Even using the most advanced design and manufacturing techniques, lenses and optical systems can still vary in quality. What every military customer wants to know is that every lens we supply them meets or exceeds the agreed specification. Because of this customer requirement we invested in a state-of-the-art MTF Testing system to automate and improve testing procedures. For instance, when qualifying a lens to demonstrate that it meets its vibration/shock performance specification - an MTF test is conducted before and after the vibration test, this ensures that no elements were able to move during the vibration test and cause a change in optical performance.

How do you address issues related to ruggedness, environmental conditions, and shock/vibration resistance in military optical systems?

All of these considerations need to be considered from the start, the lens must be designed to withstand anything it will face in operation. By drawing on our many years of experience and utilizing tools available to us in our design software, we are able to produce a design that we are 100% confident will meet the specification. However, once the designed for purpose lenses are built we again qualify them using our in-house vibration/shock and MTF facilities.

How does Resolve Optics stay up to date with the latest advancements in optical technologies to meet the evolving needs of military applications?

At Resolve Optics, we have been working with the defence industry for over two decades and understand the key features that contractors demand from their optical components and systems to ensure reliable and optimum performance. Key to keeping up to date is regular communication with existing customers and engaging generally with contractors serving the defence industry. As a specialist in custom optical design, we recognise that technology changes, and consequently are driven by our customers changing needs.

What future trends do you foresee in the demand for optics for military applications?

Optical products are widely used by military forces for imaging, targeting, and surveillance applications. These optical systems are typically installed on military vehicles, aircraft, ships, and UAVs. Some trends we note are for improved target recognition, tracking mobile targets, surveillance, and imaging, over great distances and in adverse weather conditions. We are seeing a strong demand for ultra-wide-angle lenses to be used on unmanned vehicles such as drones.

Rob Watkinson is Customer Support Manager at Resolve Optics. Rob’s role is to ensure that business customers receive outstanding support, and all their needs are met. This may involve creating customer support policies and procedures for staff to adhere to, training and observing employees and answering customer queries. He may be contacted on +44-1494-777100 or robwatkinson@resolveoptics.com

Anis Zenadji