Quick access

Contents2 Industry News: AIMPLAS | TTI, SAMTEC3 Industry News: EtherCAT Group | HANNOVER MESSE4 Industry News: IFR | Meler | KENDA5 Energy Efficiency | The Generative Economy: Imagine Circular Value Chains6 Software | Manufacturing Management System for the Digital Factory7 Automation: Manufacturing Processes with AI-Powered Visual Inspection8 Automation: IDS Imaging | Pepperl+Fuchs9 Sensors + Measurement: SICK | Resolve Optics10 Electronics & Electricity: Plasmatreat | Nexperia11 Electronics & Electricity: Schurter | Yamaichi12 Test & Measurement: Yokogawa T&M | Rohde & Schwarz13 Motors & Drives: Fauhaber | Delta Electronics14 Index15 Contacts16Companies in this issue

Dr. Fritz Faulhaber GmbH & Co. KG14 Resolve Optics Ltd10 SCHURTER AG123DS DELMIA6 Delta Electronics (Netherlands) B.V.14 Dr. Fritz Faulhaber GmbH & Co. KG14 IDS Imaging Development Systems GmbH9 Mitsubishi Electric Europe B.V8 Nexperia11 Pepperl + Fuchs SE9 Plasmatreat GmbH11 Resolve Optics Ltd10 Rohde & Schwarz GmbH & Co13 SCHURTER AG12 SICK AG10 Smartes Teknoloji Yazılım Danışmanlık San. Ve Tic. Ltd. Şti.7 YAMAICHI ELECTRONICS Deutschland GmbH12 Yokogawa Europe Solutions BV13

#2 Contents

#3 Industry News: AIMPLAS | TTI, SAMTEC

#4 Industry News: EtherCAT Group | HANNOVER MESSE

#5 Industry News: IFR | Meler | KENDA

#6 Energy Efficiency | The Generative Economy: Imagine Circular Value Chains

#7 Software | Manufacturing Management System for the Digital Factory

#8 Automation: Manufacturing Processes with AI-Powered Visual Inspection

#9 Automation: IDS Imaging | Pepperl+Fuchs

#10 Sensors + Measurement: SICK | Resolve Optics

#11 Electronics & Electricity: Plasmatreat | Nexperia

#12 Electronics & Electricity: Schurter | Yamaichi

#13 Test & Measurement: Yokogawa T&M | Rohde & Schwarz

#14 Motors & Drives: Fauhaber | Delta Electronics

#15 Index

#16 Contacts

#17

AIMPLAS Develops Demonstrator for the Digital Passport for Plastic Products

The demonstrator, designed as an interactive screen with code readers, has been made possible thanks to the collaboration of ITC Packaging and Famosa

AIMPLAS, the Plastics Technology Centre based in Spain, has developed an innovative digital totem that simulates the digital passport for plastic products, which will be mandatory for marketing products in the European Union. Companies should start implementing it from 2025 to adapt to its likely entry into force the following year, although the exact date is not yet known. This tool provides consumers with essential information about the traceability, materials, recycling, and carbon footprint of the products they purchase. Additionally, this solution developed by AIMPLAS officially demonstrates that plastic products comply with all European regulations.

As an example of what this digital passport will entail, the totem includes examples of supermarket ice cream packaging, reusable cosmetic packaging, a recycled plastic pencil holder and a toy house, which, in addition to being made with at least 90% recycled plastic, aims to educate about sustainable habits and respect for nature.

Packaging and toys are framed within the priorities defined by the European Commission's Joint Research Centre for the Sustainable Products Ecodesign Regulation.

The totem, designed as an interactive screen with code and label readers, allows users to visually and intuitively explore the information that these products could present in their future digital passports. It integrates detailed data about the product's life cycle, from its origin and manufacturing process to its material components and recycling options at the end of its useful life, as well as its impact on the carbon footprint. With this demonstrator, AIMPLAS aims to raise awareness among the industry and consumers about the importance of having verified and accessible information that promotes more responsible and circular consumption.

Regulation for end products and intermediates

The products identified by the European Commission as key to being included in the Sustainable Products Ecodesign Regulation (which encompasses the digital passport) are eleven final products (textiles and footwear, furniture, tyres, bed mattresses, detergents, paints and varnishes, lubricants, cosmetics, toys, fishing gear, absorbent hygiene products), and seven intermediate products (iron and steel, basic chemicals, non-ferrous metal products other than aluminium, aluminium, plastic and polymers, pulp and paper, glass). Additionally, three horizontal requirements will be considered (durability, recyclability, recycled content).

The development of this demonstrator for the future digital product passport has been made possible thanks to the support of the Valencian Institute of Business Competitiveness and Innovation (IVACE+i) with funds from the Generalitat Valenciana for the development of independent R&D activities by technology centres. It is framed within the Circular Economy Line promoted by AIMPLAS and represents a step towards transparency and sustainability in the plastics industry.

ITC Packaging and Famosa have collaborated in this development by providing relevant information from the technical sheets of the ice cream packaging and the toy. Both companies are working with AIMPLAS on the OASIS project, funded by IVACE+i within the aid program aimed at technology centres in the Valencian Community for non-economic R&D projects carried out in collaboration with companies for the 2024 fiscal year, funded by the European Regional Development Fund (ERDF) of the European Union under the 2021-2027 Operational Program.

TTI Announces Global Distribution Partnership with Samtec

TTI IP&E – Europe, speciality distributor of electronic components, announced the company is now an authorised distributor of Samtec, Inc. products. With this new partnership, TTI will provide a global channel for Samtec’s cables and connectors used in electronic applications.

“We are very pleased to add Samtec to our supplier line card,” said Lew LaFornara, Senior Vice President, Product and Supplier Marketing. “We look forward to bringing Samtec’s industry-leading connector, cable and fibre optic products to our global customers, many of whom look to TTI and our custom supply chain management programs to minimize supply chain risk, reduce their inventories, and streamline their purchasing processes.”

Rick Skees, Vice President of Distribution, Samtec, shared that “TTI is known throughout the industry as a leader in customer support with a commitment to quality and inventory management. We are very pleased that they will be representing Samtec products in the global distribution channel.”

The introduction of Samtec products to TTI’s portfolio means TTI will provide Samtec PCB interconnects to electronics manufacturers worldwide, simplifying customers’ BOM purchases. The full line of Samtec products are available from TTI as of Q1 2025.

EtherCAT Technology Group Hits the 8000 Member Milestone

At the end of 2024, the EtherCAT Technology Group (ETG)welcomed U.S.-based Norwalt Automation Group

Norwalt Automation joins the ETG as another leading machine builder that wants to provide the numerous advantages of EtherCAT technology to its customers today and in the future. Just like the ETG itself, Kyle Seitel, Technical Operations Manager at Norwalt, is also pleased about joining: “Without EtherCAT, our new machine would not be nearly as successful: the performance and synchronization precision of EtherCAT enable the outstanding accuracy and high throughput of this system with its many axes. In this way, EtherCAT helps us meet the high expectations of our customers and continues to do so in the future.”

The EtherCAT Technology Group continues to expand its position as the largest fieldbus user organization in the world. Hitting this 8000-member milestone, in combination with the approximately 80 million EtherCAT nodes in the field, once again confirms the success and market penetration of the technology.

Development into a global organization

The continuous membership growth of the EtherCAT Technology Group continues unabated more than 20 years after its foundation, with over 400 new members joining every year for the past 10 years. And although EtherCAT originated in Germany, the structure of the ETG is absolutely global: case in point, the number of Asian member companies has recently overtaken those from Europe. This means that 43% of members come from Asia, 42% from Europe, 14% from America and 1% from the rest of the world. According to the organization's guidelines, only legal entities such as companies or universities can become members of the ETG, not individuals.

Power Transmission and Fluid Power Pave the Way for Industry

At this year's HANNOVER MESSE from 31 March to 4 April, drive technology and fluid power will play a special role. Under the "Motion & Drives" banner, these industry segments will once again demonstrate their strength and importance by showcasing a wide range of products, from innovative and intelligent individual components to complete systems.

Expo Channel: Hannover Messe

For strongly export-oriented drive technology and fluid power companies, HANNOVER MESSE is the ideal platform to push their global business forward thanks to its highly international character. "Given the general global conditions, HANNOVER MESSE has a special role to play this year, because this is where the global course for tomorrow's industrial production will be set," says Dr. Jochen Köckler, Chairman and CEO of Deutsche Messe AG. "In the areas of automation, digitalization and international cooperation, we offer a central platform on which drive technology and fluid power companies can showcase their pioneering concepts and provide decisive impetus for a resilient industry. At the same time, the highly international nature of the event opens up ideal opportunities for export-oriented companies to tap into new markets, acquire potential new customers, and strengthen their position in global competition in the long term."

Companies that have already registered their participation include Atos, Baumüller, Bosch Rexroth, Cantoni, Festo, Flender, HAWE, IMM Hydraulik, SEW-EURODRIVE, and Schaeffler. The manufacturers will present their latest applications and components for intelligent and sustainable production. All this, under the Motion & Drives label, will be focused in Halls 4, 5, and 6.

"Power Transmission Engineering and Fluid Power components are key building blocks of machines – they provide power and movement, serve as a data source for digital value-added services, and play a decisive role in the performance of customer products. In 2025, HANNOVER MESSE with its 'Motion & Drives Community' will become a driver of innovation in the engineering business," emphasizes Hartmut Rauen, Deputy Managing Director of the Machinery and Equipment Manufacturers Association (VDMA) and responsible for the Power Transmission Engineering and Fluid Power Associations within VDMA.

Young Talent and Research Activities as the Key to the Future

The members of the Power Transmission Engineering and Fluid Power associations are increasingly involved with the problems of securing young talent and the shortage of skilled workers. Through close cooperation with research institutions such as the Research Association for Drive Technology (FVA e.V.), the Fluid Power Research Fund and the Fluid Power Education Fund, pioneering research projects are being driven forward, and urgently needed graduates are being trained.

Digitalization will continue to be a key topic at HANNOVER MESSE. The publicly funded research project "Fluid 4.0", which focuses primarily on the Asset Administration Shell (AAS) concept, is opening up new perspectives for the industry. OPC UA specifications are being developed in the area of Power Transmission Engineering to optimize data exchange in Power Transmission Engineering. Interfaces to the overarching topic of Manufacturing-X will also be addressed in order to design future data spaces for the industry, and to gear up the sector for the future.

Special Fluid Power 4.0 Show: Innovation Meets Sustainability

The special show in Hall 5, D44 at the heart of the "Motion & Drives" exhibition focus will prove to be the central meeting point for casting light on the future of fluid power and exchanging ideas and insights with experts. Exhibits and research activities on system control, energy monitoring, recycling management, carbon footprints, and IoT integration will be presented. The exhibition will show what the path to even more efficient and productive fluid power looks like, and what added value digitalization brings for manufacturers and customers alike.

“Motion & Drives” Conference Stage: Transfer of Expertise and Networking

The Conference Stage in Hall 5, D32 will be the center for transferring expertise and networking in the fields of Power Transmission Engineering and Fluid Power. In the immediate vicinity of the special FLUID POWER 4.0 show, sessions will be offered throughout the week dealing with specific topics on the latest developments in smart Fluid Power and Power Transmission Engineering. The program will be supplemented with topics focusing on Europe, India and Italy.

VDMA Power Transmission Engineering and Fluid Power in Hall 5

The joint stand for VDMA members and the information stands of the Power Transmission Engineering and Fluid Power associations together with their European sector committees CETOP and EUROTRANS, will be located in the immediate vicinity in areas E36 to E44. Seven member companies from the Power Transmission Engineering and Fluid Power sector and the Fluid 4.0 project will be exhibiting innovative products, innovations and solutions at the joint company stand.

If you want to meet the specialists live at HANNOVER MESSE, you can register for a free ticket on the fair website: https://www.hannovermesse.de/en/?open=ticketRegistration&code=5C5oC

The global market value of industrial robot installations has reached an all-time high of US$ 16.5 billion. Future demand will be driven by a number of technological innovations, market forces and new fields of business. The International Federation of Robotics reports on the top 5 trends for the robotics industry for 2025.

Artificial Intelligence – Physical, Analytical, Generative

The trend towards artificial intelligence in robotics is growing. By leveraging diverse AI technologies, robotics can perform a wide range of tasks more efficiently:

Analytical AI enables robots to process and analyze large amounts of data collected by their sensors. This helps to manage variability and unpredictability in the external environment, in high mix/low-volume’ production as well as in public environments. Robots equipped with vision systems, for example, analyze past tasks to identify patterns and optimize their operations for greater accuracy and speed.

Robot and chip manufacturers recently are investing in the development of dedicated hardware and software that simulate real-world environments. This so-called Physical AI allows robots to train themselves in virtual environments and operate by experience, rather than programming.

These Generative AI projects aim to create a “ChatGPT moment” for Physical AI. This AI-driven robotics simulation technology will advance in traditional industrial environments as well as in service robotics applications.

Humanoids

Robots in the shape of human bodies have received a lot of media attention. The vision: robots will become general-purpose tools that can load a dishwasher on their own and work on an assembly line elsewhere. Start-ups are working on these humanoid general-purpose robots.

Yet, industrial manufacturers are focusing on humanoids performing single-purpose tasks only. Most of these projects are being carried out in the automotive industry, which has played a key role in pioneering robot applications throughout the history of industrial robotics, as well as in the warehousing sector. From today's perspective, however, it remains to be seen whether humanoid robots can represent an economically viable and scalable business case for industrial applications, especially when compared to existing solutions. Nevertheless, there are many applications that could inherently benefit from the humanoid form and therefore offer market potential for robotics e.g. in logistics and warehousing.

Sustainability – Energy Efficiency

Compliance with the UN's environmental sustainability goals and corresponding regulations around the world is becoming an important requirement for inclusion on supplier whitelists. Robots play a key role in helping manufacturers achieve these goals.

In general, their ability to perform tasks with high precision reduces material waste and improves the output-input ratio of a manufacturing process. These automated systems ensure consistent quality which is essential for products designed to have long lifespans and minimal maintenance. In the production of green energy technologies such as solar panels, batteries for electric cars or recycling equipment, robots are critical to cost-effective production. They enable manufacturers to rapidly scale up production to meet growing demand without compromising quality or sustainability.

At the same time, robot technology is being improved to make the robots themselves more energy-efficient. For example, the lightweight construction of moving robot components reduces their energy consumption. Different levels of sleep mode put the hardware in an energy saving parking position. Advances in gripper technology use bionics to achieve high grip strength with almost no energy consumption.

Robots - New Fields of Business

The general manufacturing industry still has a lot of potential for robotic automation. Most manufacturing companies are small and medium-sized enterprises (SMEs). The adoption of industrial robots by SMEs is still hampered by high initial investment and total cost of ownership. Robot-as-a-Service (RaaS) business models allow enterprises to benefit from robotic automation with no fixed capital involved. RaaS providers specializing in specific industries or applications can offer sophisticated solutions quickly. In addition, low-cost robotics offers solutions for potential customers that find a high-performance robot to be oversized for their needs. Many applications have low requirements in terms of precision, payload, and service life. Low-cost robotics addresses this new “good enough” segment.

Interesting new customer segments beyond manufacturing include construction, laboratory automation and warehousing. Demand across all industries is being driven by the fact that recent crises have led to political awareness of domestic production capacity in strategically important branches. Automation allows manufacturers to nearshore production without sacrificing cost efficiency.

Robots Addressing Labour Shortage

The global manufacturing sector continues to suffer from labour shortages according to the International Labour Organisation (ILO). One of the main drivers is demographic change, which is already burdening labor markets in leading economies such as the United States, Japan, China, the Republic of Korea, or Germany. Although the impact varies from country to country, the cumulative effect on the supply chain is a concern almost everywhere.

The use of robotics significantly reduces the impact of labour shortages in manufacturing. By automating dirty, dull, dangerous or delicate tasks, human workers can focus on more interesting and higher-value tasks. Robots perform tedious tasks such as visual quality inspection, hazardous painting or heavy lifting. Technological innovations in robotics such as ease of use, collaborative robots or mobile manipulators help to fill gaps when and where needed.

New Website Completes Meler Rebranding Project

Gluing solutions provider launches new website to improve customer experience

February begins with news for Meler thanks to the launch of its new website: www.meler.eu . This milestone represents the final stage of the rebranding process that the company started in 2021, aimed at supporting and reflecting the company's sustainable growth strategy, which began in Navarra 40 years ago.

"This website represents a restructuring and updating project of Meler's entire portfolio, where the specialist brands we have been working with for several years have been organically integrated. The new website now truly reflects our company and is ready to continue growing," says Nuria Santón, Marketing and Communication Director of Focke Meler.

Main advantages of the new website

Meler's website is a showcase that receives visits from all over the world and, therefore, maintains its 5 languages (Spanish, English, French, German, and Italian), offering more visual content that guarantees a better user experience. The product portfolio has been reorganized into categories following an information architecture based on modular and responsive design criteria. It has also incorporated a filtering system that will allow customers and partners to access the information they need more intuitively.

One of the most important novelties is the incorporation of Meler's service pages: Meler Academy, Meler Lab, or Meler Engineering. These new sections reflect Meler's potential to tackle personalized projects, allowing users to assess whether their project can become a reality with the resources Meler offers. The new website faithfully reflects Meler's corporate identity, an international company but accessible through each of its subsidiaries and partners.

KENDA Europe Makes Major Change to Automotive Leadership Team

Effective January 1, 2025, Sabrina Kühl has been promoted to the role of Marketing & Product Development Director for KENDA Europe Automotive.

The position of Marketing & Product Development Director is a newly created role within KENDA Europe, designed to meet growing demand for high-quality automotive tires in the region. In this role, Sabrina Kühl will oversee marketing strategy & roll-out, working closely with the KENDA Europe Technical Centre to develop Passenger Car Radial (PCR) tires tailored to the European market. In addition to leading all marketing initiatives, Sabrina will represent the business at key industry events. The first major event in the calendar being Autopromotec 2025, in Italy at the end of May.

With deep industry expertise, Sabrina is perfectly positioned to drive the growth of KENDA’s automotive business in this area. She has worked in the tire industry since 2001 and has been part of the KENDA team for for than 8 years, serving as the Key Account Manager for several countries.

In her new role, she will continue to report to Henno Plaggenborg, Director of the Automotive Division at KENDA Europe, who comments: “Sabrina’s promotion reflects the company’s commitment to expanding its presence in the automotive tire market. We are confident that her leadership will play a pivotal role in advancing KENDA’s strategic goals, which include increasing brand awareness and further strengthening our market position in Europe.”

The Generative Economy: Imagine Circular Value Chains

What is the generative economy? And how do supply chain virtual twins play a role in this generative economy? Carlijn Goedhart, Sustainability Lead at DELMIA explores these questions in greater detail.

Energy Efficiency

According to Ellen MacArthur Foundation, a non-profit organisation committed to creating a circular economy, the three principles of a circular economy are the following:

- Eliminate waste and pollution

- Circulate products and materials (at their highest value)

- Regenerate nature

More and more companies pretend to support a circular economy by only focusing on the first and second principle. Although there is arguably a third principle that cannot be left out. In order to emphasize this principle on top of the other two principles of the circular economy, Dassault Systèmes uses the term “(re)generative economy” as part of its mission and We believe that this will be a solution to (over)consumption.

The importance of a circular economy

In our current system, we take materials from the Earth, make products from them, use these products for a while, and throw them away as waste. A take-make-use-waste model focused on consumption is not sustainable because it takes much more from the planet and society than it gives back: it leaves a negative eco-bill. As we continue like this, supplies of materials are running low, waste mountains are growing bigger and bigger, and nature suffers. All of this will affect humanity. Therefore, we have to transform from a linear system to a system that continuously reuses materials: a circular economy.

The main idea of a circular economy is reducing the consumption of natural resources, avoiding materials that become waste and therefore keep products and materials in circulation. It is the successor to the famous “3R waste hierarchy” that everyone knows: reduce, reuse, recycle. In the meantime, this list has evolved into many more Rs. In general, the main goal of the circular economy (and the R-strategies) is to retain the value of materials and products as much as possible.

There are plenty of great examples of this working in practice, for example, one of Dassault Systèmes customers’ in the automotive space made better use of scrapyard materials. They changed their internal processes to use a product for its original purpose. Instead of recycling bumpers from the scrapyard into other, lower-quality plastic parts, the bumpers are now reused. This avoids the energy required to separate, wash, shred, melt and remold plastics for recycling. In addition, there is no longer a need to buy new bumpers made from virgin materials. Furthermore, the value of the bumper material remains much higher than that of the original scrap.

Key opportunities in the circular economy transition

Ellen MacArthur Foundation highlighted a couple of key opportunities in the transition to the circular economy:

- Improving the design of products and their corresponding production processes, so that products last longer. Elements are easily repaired and reused by designing products and their manufacturing lines for product disassembly,

- Ensuring the reverse network is in place, including logistic flows of reverse products, to save products from landfills and return them to the manufacturer after use.

- Creating new value chains and optimizing material flows, so that we maximize the usage of materials by keeping them in the loop.

Virtual twin solutions are key for businesses to imagine, create and deliver circular manufacturing processes. These solutions are able to tackle all of the key opportunities to support a circular economy. The power of combining the virtual twins of the product, manufacturing and supply chain is extremely powerful, but the scope of this blog focuses in on the opportunity with the supply chain, and how the supply chain virtual twin can enable the creation of new value chains, and the optimization of material flows.

Optimizing material flows within supply chains

An example: sustainable sourcing optimization:

DELMIA Quintiq Optimized Planning enables companies to set up a virtual twin of their supply chain. A concrete example is the optimization of a sourcing plan. It helps users answer the question: “how much of which product to buy from which supplier in which week?” while taking into account constraints, costs, carbon emissions and supplier ratings. Supplier ratings are non-quantifiable factors, for example supplier compliance with standards and certifications. The choice of KPIs, including circularity metrics, and how much weight these are given, depend on the settings and can be different for each company or situation. It allows a manufacturer to make trade-offs between multiple different scenarios, such as:

- Cost vs. Sustainability with a focus on Cost: This plan minimizes costs, but sources materials from suppliers that are geographically located far from manufacturing locations, which introduces longer distribution routes.

- Cost vs. Sustainability with a focus on Sustainability: This plan sources material from local suppliers, close to manufacturing, who offer recycled materials, have sustainable business practices and use EV or rail networks for distribution. The plan involves higher costs and a lower margin than the first scenario, but generates much less indirect scope 3 emissions and ensures a more responsible value chain.

- Balanced: This plan optimizes against both costs and carbon emissions. It results in a balanced supply plan that involves a higher margin than the second scenario, but generates much less indirect scope 3 emissions than the first scenario.

Consequently, by rapidly and precisely evaluating potential scenarios in the virtual world, the supply plan design is ready to be applied in the real world and lays a foundation for the overall value chain.

Creating new value chains within and between companies

In a circular economy, waste is the new raw material. Instead of being discarded, the output of one process step becomes the input of another. Therefore, to keep products and materials circulating, circular processes have to be set up.

For example, a Dassault Systèmes customer in the aluminum industry increased the use of scrap aluminum and reduced the use of virgin materials, by changing their internal processes. The quality of the aluminum product depends on its ingredients; the quality of the scrap. Therefore, now the scrap is first carefully sorted into low/high quality “scrap buckets”. The next step is the planning of the aluminum batches, which is very complex because hundreds of properties have to be taken into account (such as quality or strength). Thanks to DELMIA Quintiq, optimal batches are composed with the available supply of scrap material, while respecting their customer’s requirements and delivery dates.

The example above illustrates an improvement of process innovation within the organization. However, circular processes go beyond a single company: complete new circular value chains should be built between different companies. Companies have an unique opportunity to join a large network of different companies in order to keep products and materials in the loop. We see initiatives already emerging within sectors where raw materials are becoming scarce, such as steel and aluminum. Key stakeholders, from metal producers to waste management companies, are exploring how materials can be kept in the cycle for longer.

Manufacturing Management System for the Digital Factory

Modular structure and user-friendly interface for a efficient and flexible production

Automation, Industry 4.0

SmartFactory is an innovative Manufacturing Execution System (MES) software developed by Smartes to digitise production processes and increase the efficiency of companies. With an infrastructure based on Industry 4.0 and IIoT technologies, it covers all equipment, from CNC and PLC-controlled machines to industrial robots, and enables the collection, monitoring and reporting of digital data. The software offers user-friendly, integrated and scalable solutions in many sectors, especially in the machining sector.

Full control and flexibility with a modular structure

Today, as traditional production methods evolve with digital transformation, the solutions offered by SmartFactory are a great advantage for companies. SmartFactory's Smart Factory solutions collect and analyse all production data in a single centre, minimising error rates and reducing labour costs with its paperless factory concept. With each digitised piece of data, users can regularly monitor their production lines, detect faults immediately and improve their operations.

The system instantly monitors the performance, status and utilisation of each machine on the production line and presents the data in easy-to-understand graphs. This allows companies to identify which processes need improvement and optimise their operations by making real-time decisions.

SmartFactory's powerful modular structure gives companies full control and flexibility over their production processes. With the Operator Interface Module, operators have easy access to work orders and can enter downtime reasons into the system. This speeds up work order management and digitises quality control and maintenance processes. The Mobile Traceability Module provides instant, hardware-independent remote access to all data when you are away from your premises. The Work Order Integration Module enables companies without ERP systems to digitise work orders; technical drawings and operational details are transmitted to operators in a digital environment. The ERP Integration Module works in harmony with your existing ERP system and transfers work orders to operator screens. Finally, the Production Planning Module facilitates daily, weekly and monthly planning and optimises your processes by eliminating delays. SmartFactory's modules give you a flexible, integrated and fully controlled structure for digital transformation.

User-friendly interface and mobile access

SmartFactory is easy to use for all types of users thanks to its user-friendly and intuitive interface. This system, which provides access at all levels from operator screens to managers, can be accessed at any time via computer or mobile devices. Its mobile-compatible structure allows the factory to be controlled from anywhere in the world, reports to be viewed instantly and decision-making processes to be accelerated.

Increasing competitiveness

SmartFactory adds value to companies on their digital transformation journey. It enables you to manage production processes with real-time data, improve traceability and achieve operational excellence. Advanced reporting and analytics enable you to drive change at every stage of your business, maximising quality while reducing production costs.

SmartFactory is an agile infrastructure for the introduction of Industry 4.0 technology into companies. The software is plug and play, so it is up and running quickly without the need for additional hardware.

Manufacturing Processes with AI-Powered Visual Inspection

Configurable without programming skills, the MELSOFT VIXIO AI-powered visual inspection software is revolutionising quality assurance across industries.

Automation, Vision & Identification

Imagine a bustling factory floor where every product that rolls off the line is a testament to meticulous craftsmanship. Yet, no matter how skilled, the human eye can tire, and defects can slip through unnoticed in those moments of fatigue. The new Mitsubishi Electric MELSOFT VIXIO software helps avoiding this. Tirelessly vigilant it ensures that every product can meet the highest quality standards.

“Our visual inspection software transforms the inspection process, making it more accurate and efficient. It performs the heavy lifting of primary screenings, identifying potential defects with unmatched precision. Doing so liberates human inspectors to focus on what truly matters—ensuring that only the finest products reach the hands of consumers” - emphasises Daniel Sperlich, Strategic Product Manager Controllers at Mitsubishi Electric, Factory Automation EMEA.

How does it specifically work?

- Learning phase: The software learns what a "good" product looks like by reviewing many examples of good and bad items, similar to studying for a test.

- Image processing: After learning, it analyses product images in real-time using algorithms to compare them against its training data.

- Decision making: Based on its analysis, the software gives products a "thumbs up" if they meet standards or a "thumbs down" if not, ensuring only quality products are sent out.

- Feedback loop: The software improves over time; if it makes mistakes, engineers can update its learning data to enhance its accuracy in recognising products.

MELSOFT VIXIO is designed for ease of use and requires no specialised programming knowledge. Its intuitive interface allows users to set up three simple processes: making the picture dataset, creating the AI model by configuration, and generating the task via low-code. It demands only building with the help of low code instead of programming, making it accessible to everyone—from seasoned engineers to newcomers in the field.

As the tool debuts across the EMEA region, it targets industries ranging from automotive to food & beverage to life sciences and promises to enhance productivity and reduce waste and energy consumption.

Industrial Streaming Camera Series

For high-quality monitoring and event recording

Automation, Vision & Identification

Would you open the machine every time to check the interaction of components or wear? It makes no sense. It is much easier to keep an eye on things with a camera. Models from the consumer sector are quite common, but they also have their drawbacks: they are often only available for a very limited time, and spare parts are usually hard to come by. With the uEye SCP and uEye SLE product lines, IDS Imaging Development Systems is now launching the "uEye Live" camera series. They specialise in monitoring tasks, deliver various live streams and even allow event recording.

The GigE cameras are designed for stand-alone operation. In addition to easy access via the web front-end (HTTP), users benefit from video streaming, hardware-accelerated video encoding and event-based recording in the camera's memory. This means that in the event of an incident, the cameras provide a valuable 'window into the past'.

Housed or embedded camera option

The uEye SCP series has a completely sealed 29x29x29 mm housing. The uEye SLE series consists of board-level models for embedded applications with different mounting options. The first uEye SCP camera is now available with the 8.3 MP IMX678 rolling shutter sensor from the Sony Starvis 2 series. The board level version and additional sensors will follow in 2025.

These surveillance cameras are industrial grade, compact and cost effective. They can deliver multiple video streams simultaneously - and thanks to Sony's Starvis 2 technology, they deliver high image quality even in low-light situations. A total of three parallel streams are available. In addition to H264, the models also offer MJPEG over HTTP for direct viewing in a web browser without the need for additional plug-ins or third-party software. The RTSP protocol ensures standardised integration of H264 streams into existing tools and applications. A web-based REST API makes it easy to integrate the cameras into machine control systems.

Accurate Volume Detection with LiDAR

The Volume3D volume detection system precisely measures the load on conveyor belts using LiDAR sensors, an evaluation unit, and a rotary encoder. It detects volume, volume flow, and many other data while simultaneously monitoring sensor contamination.

Automation, Sensor Technology

The Volume3D from Pepperl+Fuchs is easy to install, allows noncontact measurement, and is low maintenance. The system is suitable for various applications such as intralogistics and mining, boasting high accuracy, reliability, and easy integration. The Volume3D volume detection system offers precise measurements for bulk material and chaotic conveying applications. It consists of a R2000 2-D LiDAR sensor, a Multi-Scan Evaluation Unit (MSEU), an ENI58IL rotary encoder, and the required connection cables. The noncontact concept reduces maintenance costs and prevents unexpected failures.

Optional multi-sensor setup for higher accuracy

The R2000 LiDAR sensor delivers an angular resolution of 0.042° and scan rates up to 50 Hz. The R2300 is optionally available up to 100 Hz. For especially demanding applications, up to three LiDAR sensors can be connected to extend the sensing range and increase accuracy. The pre-installed software of the evaluation unit filters invalid measuring points, increasing the precision of the results.

From mining to intralogistics

The system detects the volume, flow rate, dimensions, and other load indicators of the conveyor belt. In addition, the pollution degree of the LiDAR is monitored to initiate cleaning in time. The conveying speed is detected by a rotary encoder. The system also allows for other ways to source this information. Volume3D is suitable for many applications, from intralogistics to mining. It monitors conveyor belts and enables precise control of material flows. The cost-effectiveness of the system is based on its high measurement accuracy, reliability due to the noncontact measuring principle of the 2-D LiDAR sensor system, and easy integration, even in existing systems.

IO-Link Wireless Gateway

Providing access to sensor data without the need for cables

Automation, Sensor Technology

SICK has unveiled its new IO-Link Wireless Gateway, which brings greater freedom and flexibility to industrial operations. Without the need for expensive cabling, the solution reduces installation costs, provides real-time data streaming and supports advanced analytics for improved efficiency.

As the demand for wireless connectivity and data communication grows, SICK is meeting the industry's evolving needs for intelligent industrial communication and IIoT technology with a robust, easy-to-install wireless IO-Link solution that enables data to be collected and analysed from multiple sensors.

The IO-Link Wireless Gateway works in harmony with SICK sensors and actuators. It reduces installation time and downtime, while increasing flexibility and safety. For advanced analytics, predictive maintenance and greater operational efficiency, it features an intuitive design and enables real-time data streaming to enterprise and cloud platforms.

Simple retrofit solution

Ideal for applications where wired connections are impractical or impossible, SICK's IO-Link Wireless Gateway is the next evolution of the global, bi-directional, intelligent industrial communication standard IO-Link. It enables innovative new machine designs that weren't possible before and easily retrofits existing technology for unparalleled flexibility, future-proof automation and greater scalability.

Comprising the IO-Link Bridge, IO-Link Hub and IO-Link Master, the new suite of wireless IO-Link solutions is an easy way to make sensors and actuators wireless. Both the Bridge and the Hub can be used to feed data back to the Master, with the IO-Link Hubs enabling multi-sensor connectivity via their four IO-Link ports. The IO-Link Master can support up to 16 sensors simultaneously, with the SICK Wireless IO-Link Gateway providing intelligent connectivity at distances of up to 20 m with a low latency of 5 ms.

Seamless integration for accurate, uninterrupted data acquisition

With its plug-and-play functionality, the SICK IO-Link Wireless Gateway eliminates the need for programming or complex wiring, making installation easy and hassle-free. Sensors can be easily configured remotely via the IO-Link Wireless Gateway, and the IO-Link Wireless network ensures uninterrupted data transmission and accurate data collection through dynamic frequency hopping and blacklisting. To further ensure data accuracy, localised power cabinets reduce interference, voltage drops and electrical noise.

The point-to-point wireless communication system adapts to any existing data infrastructure on the PLC, ensuring accurate data transmission. It provides access to various IIoT interfaces, such as REST API and MQTT, and multiple fieldbuses, including PROFINET, EtherNet/IP and EtherCat, using the 'Connect X' platform.

The exceptional flexibility of the IO-Link Wireless Gateway is ideal for automation solutions where wired connections are impractical or not possible in a wide range of industries, with applications such as

- Helping food and beverage manufacturers meet stringent hygiene standards by eliminating the need for cabling, which can be a source of bacteria and cross-contamination.

- Providing fast, cost-effective scalability for conveyors and cross-belt sorters by supporting more sensors over longer distances, allowing for additional sortation stations and expansion without the need for costly hardware upgrades.

- Enable real-time device-to-device communication between devices such as AMRs, AGVs and forklifts with low latency and data integrity, ensuring cohesive co-ordination and high flexibility with no cabling to minimise downtime.

Highly Efficient Image Intensifier Relay Lenses

Optimized lenses for higher image intensifier efficiency

Vision & Identification

An image intensifier is a device for increasing the intensity of available light in an optical system to allow use under low-light conditions, to facilitate visual imaging of low-light processes, to convert non-visible to a visible light source, or to provide increased light sensitivity for high-speed imaging applications. Resolve Optics has developed a reputation for successfully developing custom relay lenses for industrial partners looking to improve the efficiency of devices and instruments incorporating image intensifiers.

Rob Watkinson, Sales Manager said “A nice example of our capability in this area was when we were approached to design a custom relay lens to optimize the quality of image transfer from an intensifier to the image sensor in a high-speed range camera. Historically, most range camera designs have used off-the-shelf lenses placed back-to-back to transfer images from the intensifier to the image sensor. However, this approach produces a large amount of shading and image distortion. To overcome this inefficiency we designed a bespoke relay lens that was both compact and that eliminated the shading and distortion effects that degraded the quality of transferred images. The resultant novel f/2.8, 1 to 1.1-magnification relay lens has enabled our clients range camera to produce images with no visible distortion that are equally illuminated across the entire image area. The compact relay lens has also ensured optimal input into the microlenses on the range camera’s CCD image sensor”.

Efficient and Sustainable Cleaning with Only Compressed Air, Electricity and Water

Plasma Technology for Surface Cleaning with High Demands

Electronics & Electricity, Industrial Equipment & Supplies

Plasmatreat is expanding its portfolio to include an innovative solution for gently, intensively and efficiently removing stubborn contaminants from glass, metal and plastic surfaces. This advanced technology sets new standards in surface preparation for subsequent production steps by combining the proven benefits of Openair plasma technology with the chemical reactivity of water.

In many high-tech industries, including automotive, electronics, aerospace and medical, surface cleanliness is a critical success factor. Even the slightest contamination can impair adhesion in subsequent processes such as bonding, printing, painting or coating, thus jeopardising the quality and reliability of the end product. While conventional cleaning methods often rely on solvents or complex wet chemical processes, Plasmatreat's new HydroPlasma technology offers a reliable and efficient alternative. The innovative technology works entirely without chemicals, using only compressed air, electricity and water. HydroPlasma sets new standards in industrial surface cleaning - environmentally friendly, reliable and economical.

Most importantly, HydroPlasma enhances the effectiveness of the proven Openair Plasma technology and also enables the removal of inorganic residues, such as fingerprints, that have been difficult to remove in the past. This advanced solution offers a highly effective and resource efficient alternative to traditional cleaning methods.

Oil, salt and grease removal

This innovative, chemical-free and environmentally friendly technology uses ionised water to efficiently remove even the most stubborn contaminants such as oil, salt and grease.

The cleaning process is based on the direct injection of water into the plasma jet, where it is ionised and converted into a highly reactive jet. A specially designed nozzle directs the jet onto the desired substrate surface. The ionised water molecules achieve a cleaning effect comparable to that of detergent in warm water, reliably dissolving and removing residues.

For many years, the Openair plasma process developed by Plasmatreat has been used to optimise industrial production processes. A process gas, usually air, is ionised by a high-voltage arc. This creates a plasma jet that is directed through a specially adapted nozzle. It micro-cleans surfaces with pinpoint accuracy, activating metal, glass and plastic surfaces. It reliably removes contaminants such as dust and organic residues. Simultaneously, plasma treatment increases surface energy, making materials more wettable and ideal for subsequent processes such as bonding, painting, printing, sealing and coating.

For applications where this alone is not sufficient - for example, difficult-to-remove contaminants such as oils, greases or salts - HydroPlasma adds another powerful cleaning technology to the Plasmatreat portfolio.

Both are VOC-free, sustainable cleaning processes without environmentally harmful chemicals. As a result, they contribute to workplace safety, help companies reduce their carbon footprint and promote sustainable production.

Versatile industrial applications

HydroPlasma is particularly suitable for industries with high purity requirements. It can be integrated into existing production processes as well as into existing Plasmatreat plasma systems. The process is extremely flexible and can be used for industrial processes such as battery production or applications in the electronics industry. HydroPlasma was originally developed for metal and glass cleaning. However, its advantages are also evident in the plastics sector. The cooling effect of the water supply minimises the risk of thermal damage to sensitive surfaces, allowing gentle but effective cleaning.

The process is chemical-free and sustainable. This makes it ideal for industries such as automotive, medical and aerospace, where the highest standards of cleanliness are required. Companies benefit from improved process reliability and surface quality. It is also an environmentally friendly alternative to conventional cleaning methods.

Power Management IC-Family

Power management solution enables inductor-less designs

Electronics & Electricity

Nexperia is expanding its energy harvesting portfolio with the NEH71x0 power management IC (PMIC) family. This advanced PMIC line combines superior performance, cost-efficiency, and versatility, setting a new standard in sustainable design for low power applications. Unlike competing products, these devices eliminate the need for an external inductor, significantly reducing circuit board space and bill-of-materials (BOM) cost. It is available in a compact 4 mm x 4 mm QFN28 package. Applications include remote controls, key fobs, smart tags, asset trackers, occupancy sensors, environmental monitors, wearables, keyboards, tire pressure monitors, and any number of Internet of Things (IoT) applications.

These new PMICs represent a complete power management solution for energy harvesting: enabling engineers to extend battery life, recharge batteries or supercapacitors, and even eliminate batteries in certain designs, thanks to its cold start feature. With the NEH71x0 (NEH7100BU, NEH7110BU) PMICs, designers can choose from multiple ambient power sources such as light, kinetic/piezo or a temperature gradient. With an input power range from 15μW to 100mW, these high-performance energy harvesting ICs can convert energy with an efficiency of up to 95%. These devices include an on-chip maximum power point tracking (MPPT) adaptive algorithm to optimize the energy harvested, which adapts every 0.5 second, making the PMIC extremely responsive to changing environmental conditions.

Different protection features

The IC family integrates a range of power management features to protect batteries and storage elements, including over-voltage protection, low-voltage detection, and over-current protection. The addition of a low dropout (LDO) regulator and USB charging further reduces the BOM cost and simplifies the design process. For greater functionality, the NEH710BU variant includes I2C programmability and measurement readings, giving engineers additional flexibility and control in their designs.

By optimizing battery life and reducing the need for costly, polluting battery replacements, the NEH71x0 contributes to a more sustainable future of electronics. The family complements NEH2000, Nexperia’s first energy harvesting power management IC – a compact, low-BOM converter – by adding more advanced energy harvesting features and a new set of power management features.

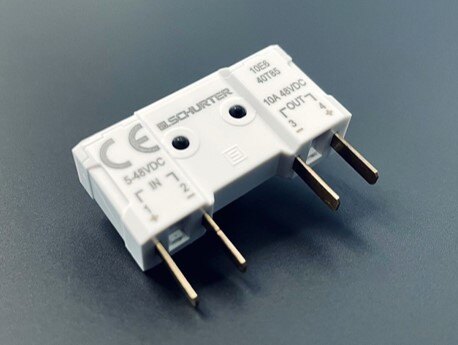

Electronic Direct Current Switch

Safe and arc-free switching with a long service life

Electronics & Electricity

The trend today is moving ever faster towards mobile applications of electrical energy. In the low-power sector, we are all familiar with this from smartphones and the like. However, the automotive and aviation sectors as well as smaller ships also work almost exclusively with direct current. In addition, electricity is also being generated directly as direct current to an ever greater extent. Photovoltaics are particularly worth mentioning here. So why convert the direct current into alternating current with losses (inverters), transport it and then convert it back into direct current with losses (rectifiers)?

Reliable arc prevention

The Schurter EDC is is an electro-mechanical microswitch that has been developed specifically for switching high direct currents. The EDC is currently the only one of its kind. Super-compact and lightweight. It switches up to 10 A at 48 VDC. The occurrence of electric arcs is prevented by the special design and the use of state-of-the-art electronic components (semiconductors). As a result, the electronic DC pushbutton has a significantly longer service life (more than 1 million switching cycles) and is more reliable than any comparable electromechanical alternative.

Board-to-Cable Connector System for Battery Applications

Reliable and process-safe with optional connector position assurance

Electronics & Electricity

The fourth Y-Lock generation from Yamaichi continues to offer the advantages of its predecessor series and complements them with new features that fulfil the special requirements of battery applications. A proven feature of the series and the V4 is the one-push locking mechanism. The flexible flat cable (FFC) or the flexible printed circuit board (FPC) is inserted into the connector using the pre-assembled stiffener. The V4 has a double locking function, firstly via two lateral locking hooks and secondly via a central locking mechanism on the long side of the insulator. The design of the side hooks also ensures the blind-mating function. The cable side is disassembled as before by simply pulling the cable.

Protection against contact and twisting

The stiffener also fulfils other functions: For example, the two-part stiffener design ensures that the pads of the FFC/FPC are protected against contact, so that the cable can also be handled safely during servicing. This feature also ensures that the plug cannot be inserted at an angle or upside down, thus preventing short circuits caused by incorrect insertion of the cable side. This ensures 10 mating cycles.

CPA - Connector Position Assurance

Yamaichi offers the mechanical CPA (Connector Position Assurance) as an option. This means that the stiffener can be permanently locked to the connector by the additional plastic part. The connection can then only be released after the CPA has been unlocked.

Low overall height

To ensure the greatest possible flexibility, the Y-Lock V4 series is available with gold or tin plating. This allows the possibilities of FPC suppliers to be catered for. The V4 is currently available in the 90° version and, with a complete height of 4.5mm, has a design that is perfectly adapted to the tight installation spaces in battery applications. Y-Lock V4 is available with different contact spacings: 1.0mm, 1.2mm, 1.8mm and 2mm in order to fulfil the various requirements for clearance and creepage distances.

The system fulfils the requirements of LV214.

Differential Probe Series for High-Voltage Measurements

Broad bandwidth for next generation power electronics development

Electronics & Electricity, Test & Measurement

Yokogawa Test & Measurement announced the release of the PBDH0400 series differential probe with a maximum input voltage of 2000 V and a frequency bandwidth of 400 MHz. The differential probes in this series are capable of providing the measurements required for the development of the next generation of high-speed power devices.

Development background

With increasing emphasis on measures to help decarbonise all aspects of society, there is a need to improve the energy efficiency of motors and inverters used in the transport and renewable energy sectors. This need is particularly acute in the power electronics industry, where the increase in applications for - and production of - next-generation power devices based on silicon carbide (SiC) technology requires ultra-precise measurement of high-voltage and higher-speed signals.

This task requires measurements to be made from an ungrounded (floating) potential, which necessitates the use of differential probes rather than standard probes. Yokogawa Test & Measurement therefore set out to develop wide-bandwidth differential probes capable of measuring high-voltage and high-speed signals.

High voltage and wide bandwidth measurement

Initially, two models of the PBDH0400 series will be available: model 702922 with a maximum input voltage of 2000 V and model 702921 with a maximum input voltage of 1000 V.

For accurate waveform monitoring of fast-changing signals common in electric vehicle (EV) and clean energy applications, the PBDH0400 Series differential probes measure voltages above 1000V and offer a wide frequency range from DC to 400MHz. This capability is of particular benefit to developers of next-generation inverters, enabling them to accurately monitor minute changes in high-speed switching signals. In addition, excellent noise immunity allows detection of events that can cause unexpected anomalies, including waveform overshoot and ringing.

The PBDH0400 series features Yokogawa's probe interface, which saves both cost and space by eliminating the need for an external power supply when connected to a Yokogawa oscilloscope. In addition, the interface automatically sets the probe attenuation ratio so that measurement can begin immediately upon connection to the instrument. Combining the PBDH0400 with Yokogawa's 12-bit DLM5000HD or DLM3000HD oscilloscopes enables more accurate waveform measurements.

The main markets for the new probe series are automotive electronics, including inverters and motors, power electronics and mechatronics, including industrial equipment.

PC-Based Oscilloscope Software Solution

View, analyse, document and share oscilloscope measurements more easily and effectively

Test & Measurement

R&S ScopeStudio is a new software solution from Rohde & Schwarz that transfers the capabilities of the MXO series oscilloscopes to a computer. This PC-based oscilloscope application facilitates the viewing, analysis, documentation and sharing of oscilloscope measurements away from the oscilloscope hardware, presenting a more accessible solution for individual users and development teams.

Smoother workflows

Users can import oscilloscope waveforms or entire sessions – a blend of captured waveform data and instrument setup files. The subsequent measurements and analysis capabilities mirror what a user would experience on their MXO oscilloscope. However, the application offers three key advantages. First, since users can view and analyze previously acquired data away from the instrument, it leaves the oscilloscope free for others to use. Second, engineers can use PC tools to more efficiently document designs. This not only enhances productivity but also improves the quality of images and annotations by leveraging the flexibility of additional PC resources. Finally, research and development teams can share measurement results more effectively with remote locations, partners, suppliers and customers. The need to share technical measurement details is common in development teams, and this PC-based oscilloscope application simplifies the process.

The standard features of the application include R&S SmartGrid, cursors, over 40 automated measurements, mathematical functions, filters and spectrum viewing of time-domain signals. Protocol decoding support for I²C, SPI, RS-232/UART, CAN, CAN-FD, CAN-FL, LIN, SENT, MilStd 1553, ARINC 429 and SPMI serial buses will be available soon. The new R&S ScopeStudio PC application software for the MXO 4, MXO 5 and MXO 5C oscilloscopes is now available.

High-Performance DC Motors with 12 mm Diameter

Designed for flexibility and a wide range of applications

Motors & Drives, Expo Channel: Hannover Messe

The new Faulhaber SXR motors offer standard higher performance and a broader range of configuration options to meet the demands of modern drive solutions. They provide flexible voltage variants from 3V to 18V as well as different bearing configurations. Additionally, the motors can be customized – from front and rear shaft modifications to options for vacuum and temperature environments. The optimized rotor balancing ensures longevity and smooth operation. At the core of the new SXR family is the innovative hexagonal coil with a high copper filling factor and straight wiring. This technology delivers significantly enhanced performance and efficiency compared to traditional pin coils. Additionally, a new magnet grade improves magnetic induction amplitude and temperature stability.

Compact and powerful

All components in the SXR series are RoHS compliant, and the electrical connections offer flexible configuration options. The main markets for this product line include high-tech industries that rely on quality, reliability, and an outstanding power-to-volume ratio. These include sectors such as prosthetics, surgical tools, metrology, semiconductor processing, and automation solutions.

Highly Efficient PM Reluctance Motor Series

Compact series for cost effective fan and pump applications

Expo Channel: Hannover Messe

Delta Electronics announces the launch of its MSI motor series in the EMEA region. Designed as a high-efficiency PM reluctance motor, the MSI series brings unparalleled compactness, energy savings, and integration capabilities to fan and pump applications. With options including flange, foot, and flange/foot versions, as well as speeds of 1500 rpm and 3000 rpm, the MSI series is set to redefine industrial motor performance.

Compact design

The MSI motor series revolutionizes motor design with its compact form factor, offering a size reduction of 1-2 frame sizes compared to traditional induction motors. This smaller size saves valuable installation space while meeting IE5 efficiency standards, making it an environmentally conscious choice. The motors deliver outstanding energy savings, helping industries lower operating costs and reduce carbon emissions, supporting global sustainability initiatives. These features position the MSI motors as a valuable solution for wholesalers, distributors, and system integrators across various industrial applications.

Seamless integration and easy setup

Delta has prioritized ease of use with the MSI motor series, ensuring installation dimensions match those of standard IM motors for straightforward replacement. Additionally, motor parameters are preloaded into Delta´s MS300, CP/CFP2000, and VP3000 frequency drives, allowing for quick and effortless system setup. This compatibility reduces commissioning time and simplifies operational processes, providing businesses with an efficient, cost-saving solution.

Engineered to deliver consistent and precise performance, the MSI motors operate with reduced noise—5-10 dB lower than standard motors—and minimized vibration levels, creating a quieter and more stable environment. These features enhance reliability and accuracy, making the MSI series ideal for fan and pump operations in demanding industrial settings.

3

3DS DELMIA 6D

Delta Electronics (Netherlands) B.V. 14I

IDS Imaging Development Systems GmbH 9M

Mitsubishi Electric Europe B.V 8N

Nexperia 11P

Pepperl + Fuchs SE 9 Plasmatreat GmbH 11R

Rohde & Schwarz GmbH & Co 13S

SICK AG 10 Smartes Teknoloji Yazılım Danışmanlık San. Ve Tic. Ltd. Şti. 7Y

YAMAICHI ELECTRONICS Deutschland GmbH 12 Yokogawa Europe Solutions BV 13TIMGlobal Media BV

177 Chaussée de La Hulpe, Bte 20, 1170 Brussels, Belgium

o.erenberk@tim-europe.com - www.ien.eu

- Editorial Director:Orhan Erenberko.erenberk@tim-europe.com

- Editor:Kay Petermannk.Petermann@tim-europe.com

- Editorial Support / Energy Efficiency:Flavio Steinbachf.steinbach@tim-europe.com

- Associate Publisher:Marco Marangonim.marangoni@tim-europe.com

- Production & Order Administration:Francesca Lorinif.lorini@tim-europe.com

- Website & Newsletter:Marco Prinarim.prinari@tim-europe.com

- Marketing Manager:Marco Prinarim.prinari@tim-europe.com

- President:Orhan Erenberko.erenberk@tim-europe.com

Advertising Sales

Tel: +41 41 850 44 24

Tel: +32-(0)11-224397

Fax: +32-(0)11-224397

Tel: +32 (0) 2 318 67 37

Tel: +49-(0)9771-1779007

Tel: +39-02-7030 0088

Turkey

Tel: +90 (0) 212 366 02 76

Tel: +44 (0)7594 239 182

John Murphy

Tel: +1 616 682 4790

Fax: +1 616 682 4791

Incom Co. Ltd

Tel: +81-(0)3-3260-7871

Fax: +81-(0)3-3260-7833

Tel: +39(0)2-7030631

- IEN Europe WebMag February 2026 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- IEN Europe WebMag January 2026 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag IEN Europe December 2025 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag August 2025 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag July 2025 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag May 2025 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag February 2025 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag January 2025 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag December 2024 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- IEN Europe SPS WebMag 2024 IEN Europe special issue for sps 2024 in Nuremberg, November 12 to 14.

- IEN Europe WebMag August 2024 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag IEN Europe July 2024 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- IEN Europe May 2024 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag HANNOVER MESSE 2024 Special issue for Hannover Messe 2024, April 21 - 26

- WebMag January/February 2024 IEN Europe presents Industry News, Products and solutions for industrial decision makers in the pan-European B2B market.

- WebMag December 2023 Highlights Products and Solutions sps and from 2023

- IEN Europe November Webmag Special SPS As the industrial world gears up for the 2023 SPS Show in Nuremberg, attendees and exhibitors alike are eagerly awaiting the opportunity to delve into the latest trends and innovations that promise to reshape the future of industrial automation and techno

- IEN Europe April WebMag Throw an eye to this web magazine dedicated to the coming Hannover Messe 2023! We wish to see you there as well. Have a nice and interesting reading

- IEN Europe Jan/Feb 2023 Webmag Dear readers, Happy New Year to you! IEN Europe is coming back this new year with a special focus on robotics and digital automation.

- #6 AI IEN - December 2020 Discover our latest edition of our digital magazine: AI IEN!

- IEN Europe December Last issue of 2020, IEN Europe December highlights the key trends in the IoT & e-mobility, Automotive, and Identification & Vision Systems fields.

- IEN Europe November - SPS Webmag Discover in this digital issue the best technology showcased at the upcoming SPS virtual exhibition!

- #5 AI IEN - October 2020 We are delighted to release the fifth issue of AI IEN! With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.

- Covid-19 Special e-magazine Don't miss our new issue on Covid-19 to discover the most innovative Industrial answers to the pandemic.

- #4 AI IEN - June 2020 Don’t miss the fourth issue of AI IEN! With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.

- #3 AI IEN - April 2020 Don’t miss the third issue of AI IEN! With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.

- #2 AI IEN - February 2020 Don’t miss this new issue of AI IEN! With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.

- SPS Webmag November Discover in this digital issue the best technology showcased at the upcoming SPS - Smart Production Solutions 2019!

- #1 AI IEN - September 2019 We are delighted to announce the launch of our new digital magazine AI IEN. With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.