Quick access

Industry News: Regal Rexnord and ABB | Alliance for Food Automation3 Industry News: Siemens | Kontron & congatec4 Industry News: Fraunhofer IIC | Endress+Hauser5 Automation: Enhancing Manufacturing Efficiency6 Automation: Wiesemann & Theis | Mitsubishi Electric7 Automation: Sonair | Siskon8 Automation: Maintenance 4.0: Data as an Early Warning System9 Automation: Acromag | Hans Turck10 Automation: ifm | Softing Industrial11 Automation: Extending Process Control: How Edge Intelligence and Lifecycle Separation Enable Smarter, More Resilient Industrial Operations12 Motors & Drives: How Electromechanical Actuation is Making Electric Flight a Reality13 Motors & Drives: Nebtesco Europe | Leine Linde | Nord14 Electronics - Electricity: New Connector Contact Plating15 Electronics - Electricity: Tsubaki Kabelschlepp | TDK Lambda16 Electronics - Electricity: Bopla | Smiths Interconnect17 Electronics - Electricity: PULS | Omega Energy Technologies18 Index19 Contacts20Companies in this issue

Hans Turck GmbH & Co. KG10ABB Ltd12 Acromag Inc.10 Altair Engineering GmbH6 Bopla-Gehäuse Systeme GmbH17 Getriebebau NORD GmbH & Co. KG14 Hans Turck GmbH & Co. KG10 ifm electronic gmbh11 Leine & Linde AB14 Mitsubishi Electric Europe B.V7 Nabtesco Precision Europe GmbH14 Omega Yüksek Teknolojileri18 Pepperl + Fuchs SE9 PULS GmbH18 Regal Rexnord Corporation13 Siskon Endüstriyel Otomasyon Sistemleri San. Ve Tic. A.S.8 Smiths Interconnect17 Softing Industrial Automation GmbH11 Sonair8 TDK-LAMBDA Germany GmbH16

#2

#3 Industry News: Regal Rexnord and ABB | Alliance for Food Automation

#4 Industry News: Siemens | Kontron & congatec

#5 Industry News: Fraunhofer IIC | Endress+Hauser

#6 Automation: Enhancing Manufacturing Efficiency

#7 Automation: Wiesemann & Theis | Mitsubishi Electric

#8 Automation: Sonair | Siskon

#9 Automation: Maintenance 4.0: Data as an Early Warning System

#10 Automation: Acromag | Hans Turck

#11 Automation: ifm | Softing Industrial

#12 Automation: Extending Process Control: How Edge Intelligence and Lifecycle Separation Enable Smarter, More Resilient Industrial Operations

#13 Motors & Drives: How Electromechanical Actuation is Making Electric Flight a Reality

#14 Motors & Drives: Nebtesco Europe | Leine Linde | Nord

#15 Electronics - Electricity: New Connector Contact Plating

#16 Electronics - Electricity: Tsubaki Kabelschlepp | TDK Lambda

#17 Electronics - Electricity: Bopla | Smiths Interconnect

#18 Electronics - Electricity: PULS | Omega Energy Technologies

#19 Index

#20 Contacts

Regal Rexnord and ABB Robotics Join Forces to Extend the Operational Range of Cobots

The companies are collaborating to seamlessly integrate collaborative 7th axis technology

Regal Rexnord Corporation has joined forces with automation leader ABB Robotics to simplify integration of its GoFa™ cobots into 7th Axis Cobot Transfer Units (CTUs) from Thomson, one of Regal Rexnord’s leading linear motion brands. This collaboration makes the Thomson Movotrak™ CTU the first cobot 7th axis technology that ABB Robotics has certified for use in its partner ecosystem.

“Until now, anyone wanting to use a single, plug-and-play ABB cobot on multiple workstations faced what could be days of programming and communications challenges. As part of the ABB Robotics partner ecosystem, we have preconfigured our Movotrak CTU, ensuring rapid deployment with ABB cobots right out of the box. Integrators, distributors, and end-users can now invest more time using the 7th axis to solve productivity problems than dealing with complex integration details,” said Kevin Zaba, EVP and President, Automation & Motion Control segment of Regal Rexnord.

The Thomson Movotrak CTU 7th Axes offer an extended operating range of up to 10 meters, flexible mounting options and collision detection. The Thomson linear units are integrated with other Regal Rexnord components, including Boston Gear gearheads, Huco couplings, and Kollmorgen motors and software for a complete, high-level assembly with one part number.

“This collaboration with ABB Robotics is a great example of how our differentiated Regal Rexnord technologies can be integrated into high-impact, customer-ready solutions,” said Louis Pinkham, CEO of Regal Rexnord. “By combining the technical expertise of our Thomson, Kollorgen, Boston Gear, and Huco brands into a seamless, 7th axis system available for the ABB Robotics partner ecosystem, we’re making it easier for customers to unlock greater productivity and flexibility in their automation strategies. It also reflects our ongoing commitment to innovation and delivering value through system-level thinking.”

Strategic Alliance on Food Industry Automation

The goal of the alliance of the companies Bizerba, FANUC, KILIVATIONS and Schmalz, announced at automatica 2025, is to drive the development and implementation of forward-looking automation solutions in a practical, innovative and customer-centric way

The market is increasingly moving towards continuous line production. Yet many companies still face manual challenges in the so-called End-of-Line area – where food products are labeled, inspected, stacked or palletized after packaging. Growing labor shortages are increasing the pressure to act. This new partnership addresses these challenges with a holistic solution approach.

Complementary expertise for the entire line process

Each partner contributes its specific know-how to the alliance: Bizerba is responsible for weighing, labeling, slicing and inspection technologies and takes on the role of system integrator. FANUC contributes cutting-edge robotics and control technologies. KILIVATIONS brings years of expertise in the development of robotic applications and automation solutions. Schmalz adds extensive knowledge in gripping and vacuum technology – tailored specifically to the requirements of delicate food products.

At automatica 2025, the four companies presented a first milestone of their partnership: a modular, fully automated sandwich station for hygienic, contact-free handling of fresh food. The system combines precise slicing technology with state-of-the-art robotics, advanced vacuum gripping systems and high-precision dosing – enabling pinpoint production of snacks “on demand”, contactless and efficient.

Future-ready automation

A wide range of projects is already underway – focusing on product handling, case loading and palletizing in the End-of-Line area of the food industry. Bizerba acts as the central point of contact and integrator of the overall solution.

Oliver Deifel, Director Global Customer Solution Center at Bizerba, emphasizes: “This strategic partnership is a perfect match and a key element of our Bizerba strategy to deliver holistic solutions for the food market. Our goal is to transform the entire line process downstream of the packaging machine into continuous, scalable automation concepts. As the central integrator, we combine our own portfolio with the specialist knowledge of our partners – efficient, future-ready and customer-focused.”

The combination of deep industry knowledge, technological excellence and many years of experience across industries makes this new alliance a powerful driver for transformation in food processing.

Siemens completed the acquisition of ebmpapst’s industrial drive technology business

Addition to the Siemens Xcelerator portfolio mainly in the range of 24 and 48 V motors for intelligent, battery-powered drive solutions.

Siemens AG closed its acquisition of ebm-papst's industrial drive technology business. In the future, it will be marketed using the name "Mechatronic Systems" at Siemens. The business has about 650 employees and its portfolio includes intelligent, integrated mechatronic systems in the extra-low voltage protection range, innovative driving systems used in free-moving, driverless transport systems, and other applications. This acquisition complements the Siemens Xcelerator portfolio, strengthening Siemens' position as a leading provider of flexible manufacturing automation solutions. Integrating the new portfolio into the existing automation portfolio and leveraging Siemens' global sales network will open up new markets and significant business potential in the field of intelligent, battery-powered drive and robot solutions.

“The new portfolio elements significantly expand and enhance our offerings to customers who want to automate and digitalize their production processes in smart factories. Our integrated mechatronic drive systems offer increased flexibility, productivity and efficiency in the growing global market for conveyor and autonomous transport systems, including mobile robots, driverless transport systems and shuttles," explains Achim Peltz, CEO of the Motion Control Business Unit at Siemens Digital Industries. Their seamless compatibility with Simatic controllers and the software-based safety solution Safe Velocity for mobile robotics offer extra advantages.

The expanded portfolio includes two main variants: the Simotics E-1EE1 (brushless internal rotors), which are particularly suitable for battery-powered conveying, storage and sorting systems; and the Simotics E-1EV1 (brushless outrunners), which impress with their high efficiency and compact design in intralogistics applications. The portfolio is available in 24 V and 48 V versions. The portfolio also offers transmission solutions, which are only available in conjunction with Simotics E motors. A notable innovation is the Simotics E ArgoDrive driver steering system, which was specially developed to meet the growing demands of intralogistics and automated production. Available in Light, Standard and Heavy variants, it enables the safe and precise omnidirectional control of automated guided vehicles, even when carrying heavy loads.

Locations in Germany and Romania

These systems support Siemens' sustainability goals by providing energy-efficient solutions and helping create flexible, scalable and secure digital factories. The newly integrated business comprises three locations: two in Germany (St. Georgen and Lauf an der Pegnitz) and one in Romania (Oradea).

The ebm-papst Group first announced its intention to sell its Industrial Drive Technology (IDT) division to Siemens AG in March of 2024, and both parties signed an agreement to this effect. The sale to Siemens AG has now been completed, giving IDT access to the international market through Siemens' global Sales organization. All of the division's employees have been taken on by Siemens. The parties involved have agreed to not disclose the price.

congatec Acquires Majority Stake in Kontron Subsidiary JUMPtec

congatec becomes 96% shareholder in JUMPtec GmbH by means of a capital increase and acquires the module subsidiaries in the USA and Malaysia.

Kontron and congatec GmbH announced the agreement for congatec to become 96% shareholder of Kontron's subsidiary JUMPtec by means of a capital increase. The signing and closing took place on July 1, 2025. The registration under commercial law will follow shortly. congatec is a portfolio company of DBAG (Deutsche Beteiligungs AG) Fund VIII.

Through the investment, congatec holds 96% of JUMPtec and 100% of the subsidiaries Kontron America Modules LLC, USA and Kontron Asia Embedded Design Sdn Bhd, Malaysia. The transactions will presumably lead to cash inflows of more than EUR 100 million at Kontron. Furthermore, EBITDA in Q2 2025 will increase by EUR 50-70 million. In the event of DBAG's exit from congatec, Kontron will benefit from additional performance-related proceeds. The correspondingly improved EBITDA guidance and an adjustment of the revenue expectation for the full year 2025 will be available when the results for the second quarter 2025 are published. JUMPtec generated sales of around EUR 90 million in 2024.

"The cooperation bundles technological expertise and secures us access to high-performance modules in the long term," says Hannes Niederhauser, CEO of Kontron AG. "At the same time, we are strengthening our production and expanding our range of embedded and system solutions."

Kontron has been producing COMs for congatec at international locations since May 2025. Global manufacturing brings advantages in terms of costs, delivery capability and the response to geopolitical challenges such as tariffs or local market requirements.

Listening for Damage to Wind Turbines

Maintaining wind turbines and identifying potential vulnerabilities is expensive and time-consuming, especially when they are located offshore. As a result, rotor blades are often simply replaced, a costly process, when damage is merely suspected. The Fraunhofer Institute for Integrated Circuits IIS, working in concert with the Fraunhofer Institute for Wind Energy Systems IWES, has developed a solution that can be used to identify cracks and breakages inside the blades remotely at an early stage.

Cracks, breakage and erosion in rotor blades are common causes of failure in wind turbines. Offshore wind farms are at special risk, as they are exposed to exceptionally strong winds, rain and other severe weather conditions at sea. Because these facilities are hard to access, inspections are costly and time-consuming, which is why rotor blades are sometimes simply replaced when damage is merely suspected. The costs can run to well over 200,000 euros per blade per incident.

Structure-borne sound sensors detect damage

A division of Fraunhofer IIS is working with Fraunhofer IWES on a solution: “Our goal is to use acoustic emission sensors to reliably monitor damage to rotor blades remotely, thereby helping to ensure that wind turbines are available and do not fail,” says Björn Zeugmann, group manager at Fraunhofer IIS in the area of analog integrated circuit design, describing the project’s objectives.

To that end, he and his colleagues worked together to develop a special chip used in the sensors. The sensors, which are stuck to the individual rotor blades from inside, absorb sound waves traveling through the structure of the blades. One challenge is that unlike with a steel beam, for example, the material is not homogeneous. Instead, rotor blades consist of different layers. The newly developed chip captures signals known as surface waves, which are created in the event of damage such as a crack. It then transmits these signals, for example via mobile communications.

What makes this technique special is that unlike conventional measurement systems such as radar systems or drones that collect and transmit all the raw data, the Dresden-based researchers’ new chip transfers only anomalous information: “We use an acoustic system that detects damage based on the sounds it makes, so it can tell the difference between a crack that is forming inside the rotor blade and a break, for example,” Zeugmann explains. Fraunhofer IWES developed this acoustic solution in a previous project. Extracting characteristic features makes it possible to significantly reduce the data volume so it can be transmitted via a mobile network in the first place. “Our chip is always listening, which means ideally it can classify and transmit information on potential damage from inside the rotor blade itself.”

Reducing unnecessary service missions

Going forward, this should make it possible to determine, first, whether damage has in fact occurred at all and the turbine needs to be shut down in the worst case. Second, it will also help reduce the number of unnecessary service missions to hard-to-reach offshore wind farms and optimize service because damage can be monitored over a longer period. If the damage gets worse and emits noise, the sound is detected, so technicians can perform a targeted inspection and repair the issue as needed.

Compared to existing measurement methods, the new solution is smaller and more energy-efficient and uses significantly less data since it transmits smaller data packages. This means there is also no need for a broadband internet connection to transmit relevant information from the wind farms to the mainland.

Development of lightning strike detection

In two prior projects, Fraunhofer IIS and Fraunhofer IWES already worked together to develop an initial prototype of the chip that can be used to detect damage. The successor project, now in progress, was launched on June 1. In the project, the researchers are planning to expand the overall system so it can also detect lightning strikes – and the potential consequences – down the road. This has not been possible thus far, but especially for offshore wind farms, this additional information is crucial.

Zeugmann is delighted at how far the new technology has come: “I’m fascinated by working in a field of the future like the energy transition and creating value for society that way.”

Endress+Hauser Acquires Full Ownership of CodeWrights from Pepperl+Fuchs

Endress+Hauser is now the sole owner of the software company CodeWrights GmbH, based in Karlsruhe, Germany. The Swiss specialist in measurement and automation technology acquired the remaining 33 percent of the shares from the sensors and electronics manufacturer Pepperl+Fuchs with effect from 1 July 2025. Since 2002, Endress+Hauser held two-thirds of the shares, while Pepperl+Fuchs owned the remaining third.

CodeWrights was founded in 2002 as a joint venture between Endress+Hauser and Pepperl+Fuchs and employs nearly 50 people. As a service provider, the company develops customized software solutions for providers of measurement and automation technology, for example apps and cloud applications, software for industrial automation and embedded software for devices. This has contributed to CodeWrights’ profitable growth and its reputation as a trusted software partner.

Professional team and strong business model

“We are excited to assume full ownership of CodeWrights. At the same time, we would like to thank Pepperl+Fuchs for more than 20 years of constructive partnership,” says Dr Rolf Birkhofer, managing director of Endress+Hauser Digital Solutions, the Group’s product center for the Industrial Internet of Things (IIoT). “We believe strongly in the expertise of the team and the strength of the business model. Together, we look forward to driving further growth and success.”

“We look back on decades of successful collaboration built on mutual trust and respect, for which we would like to express our genuine appreciation. We are confident that, with Endress+Hauser as the sole owner, CodeWrights is ideally positioned to drive its strategic development and realize its full potential,” says Lutz Liebers, COO for Process Automation at Pepperl+Fuchs.

No changes for customers

“By transferring the shares, we are creating a clearer ownership structure and strengthening our company’s strategic ability to act. This decision enables faster coordination and provides new impetus for our shared growth,” adds Thomas Debes, managing Director CodeWrights GmbH. He emphasizes that the acquisition will have no impact on the service provider’s day-to-day operations. “CodeWrights will continue to serve all customers with the same commitment and maintain its established service portfolio. Employees at both CodeWrights and Endress+Hauser can expect continuity in their work and collaboration.”

Enhancing Manufacturing Efficiency

To improve efficiency of its stamping processes for future production runs, Ford Mexico worked with Altair to explore the possibility of using Altair's machine learning and predictive analytics solution to support its business objectives. Authors: John Fisher, Senior Sales Director EMEA, Altair & Alberto Ochoa Frías, D&R and Stamping Process Engineer, Ford

Automation, Industry 4.0

Today’s automotive manufacturers face increasing pressure to innovate rapidly while optimizing their development processes and material usage, making efficient production essential for maintaining an edge in a highly competitive market. In this context, Ford Mexico, headquartered in Mexico City, saw the need to streamline its stamping process, and – being a long-time customer – turned to the Altair team to solve this challenge.

Sheet metal forming in the automotive industry

Sheet metal stamping is fundamental to the automotive manufacturing industry. A wide range of different tool, die, and process combinations are employed to create an equally diverse array of components. Traditionally, determining the optimal stamping process for a specific part design has been a time-consuming and labour-intensive task, heavily dependent on the stamping engineer’s expertise and experience. To address this issue, Ford Mexico began documenting successful metal stamping production runs over a 5-year period. Management’s goal was to capture in-house domain knowledge and best-practices to explore ways to speed the selection of the best stamping process for future production runs to enable business benefits including increased plant efficiency and part quality, reduction of scrap material, and the ability to rapidly train new personnel.

Finding the right process

In many production facilities, there are multiple sheet metal stamping processes available to form nested and individual parts, including progressive, transfer, and tandem press lines. For a specific part design, numerous factors come into play to identify the optimal or most efficient stamping process, such as the material type, thickness, part width, and desired surface finish.

The success or failure in selecting the right process depends significantly on the experience and expertise of the manufacturing process engineer. However, increasing design complexity, non-conventional material types, and a multitude of process combinations can pose challenges even for the most seasoned process engineers, necessitating a labour and material-intensive trial-and-error prove-out process.

Cutting material waste

Material utilization is a particularly critical benchmark. Most automotive plants expect around 60% material utilization in their stamping mills while the remaining 40% is wasted. Ford aimed to improve these metrics while also improving the accuracy of selecting the optimal stamping process on the first attempt and increasing First Time Through (FTT) rates.

To achieve these goals, Ford Mexico started documenting and accumulating a valuable asset: large amounts of clean data associated with their successful production runs.

Spanning a 5-year period, process engineers recorded successful stamping processes for thousands of parts. Captured in this historical data were valuable insights but the question now was how they could use this information to help automate and guide the selection of best stamping process for a given part design.

Handling the data with Altair

First learning of Altair® Knowledge Studio® through an Altair technology briefing, Ford Mexico approached Altair to explore the possibility of applying Altair’s machine learning and predictive analytics solution to support their business objectives.

Leveraging the data Ford collected for over 3,000 stamping processes identified as being representative of future requirements, Ford’s stamping domain experts and Altair’s solution architects collaborated to develop an accurate, reliable machine learning model with Knowledge Studio.

Knowledge Studio offers 15 different machine learning models allowing users to explore, select and train the model that best fits their data. Using subsets of the data, the team ran a series of tests to determine which was most effective. With an accuracy rate of over 90%, the decision tree model produced the most consistent results. In the process, a surprising – and valuable – discovery was made. In terms of selecting the optimal stamping process, the most important factors are the overall dimensions and thickness of the finished part.

Individually, these factors are insufficient for making a final decision. However, when combined with all other data points, Knowledge Studio’s machine learning algorithm provided Ford with results that are nearly 100% accurate.

Improved processes and training

The machine learning predictive capabilities of Knowledge Stu dio demonstrated high accuracy and effectively automated much of the stamping process selection. By minimizing manual trial-and error process validations and rework, more time was available for stamping process engineers to address the most difficult and complex part designs further enhancing production efficiency and business value.

Overall, projected throughput increased threefold, while improvements in FTT rates led to reduced rework time – all accomplished without the need for additional resources.

Additionally, the Knowledge Studio machine learning model successfully captured the company's in-house domain knowledge. This supported a faster learning curve for training new personnel, ensuring that valuable expertise was efficiently passed on to new employees. By using this technology, the company has enhanced its training processes and maintained a knowledgeable workforce.

Single Pair Ethernet Network Extender

SPE device for 1 km network range via any 2-wire connection

Automation

Network specialist Wiesemann & Theis presents the new Network Extender SPE. It enables the transmission of Ethernet data over distances of up to 1 km and more, based on the new Single Pair Ethernet (SPE) technology. The converter set can be used to connect any Ethernet devices over long distances. The connection can be implemented using any two-conductor cable, with maximum length depending on the cable used. SPE can bridge distances of up to 1000m, with two extender sets even further.

PoE-supply

The Network Extender SPE is designed for industrial use and supports applications in areas such as building automation, manufacturing and traffic engineering. Thanks to the Power-over-Ethernet (PoE) supply, the device allows both data transmission and power supply via a single cable. Commissioning is quick and easy via Plug & Play and without the need for IP configuration. The device features high immunity to interference and complies with the applicable standards for industrial use.

Predictive Maintenance Shields Supply Chains

According to the International Society of Automation, factories worldwide lose 5-20% of their productive capacity to unplanned downtime. With supply chain disruptions increasing, Mitsubishi Electric's predictive maintenance solutions help manufacturers identify equipment failures before they occur, maintaining operational continuity.

Automation

Research from Arimo shows the average plant loses 15 hours weekly to downtime, with production lines facing approximately 20,000 interruptions annually. According to Resilinc, manufacturing disruptions increased by 30% in the first half of 2024 compared to last year, with factory-specific issues rising by 40%.

Higher transport costs and worker shortages have amplified the impact of each stoppage. In this environment, predicting maintenance needs gives companies a significant advantage. Mainly due to the early indication of a fault, allowing it to be fixed during the next maintenance period, which means longer machine uptime.

AI-Maintenance In Figures

"When we can spot equipment failures weeks before they happen, the whole supply chain benefits," explains Daniel Sperlich, Strategic Product Manager Controllers at Mitsubishi Electric Europe. "We can order spare parts for repair that can be stored until the next planned maintenance phase. And, we allow the production line to continuously run, without any interruptions - including those caused by a lack of spare parts when these are needed ‘here and now’. " As Rafi Ezra, Managing Partner US Industrial Market at IBM Services states: "AI-powered maintenance solutions can cut downtime by up to 50%, reduce breakdowns by 70%, and lower overall costs by 25%."

Industry Response to The Needs

Mitsubishi Electric has developed several predictive maintenance systems. Their MELFA FR series robots with Smart Plus cards track performance and identify potential issues early. The company's MELSERVO-J5 servo amplifiers use AI to detect wear in critical mechanical parts by analysing vibration patterns, tension changes or backlash. Additionally, the FR-E800 Series inverters feature Corrosion Alert System and Life Diagnostics Function to monitor component conditions. "Today, implementing predictive maintenance tools is no longer just an advantage but a necessity for companies that want to stay competitive," emphasises Daniel Sperlich, Strategic Product Manager Controllers from Mitsubishi Electric. "Our solutions help manufacturers address problems before they affect their production lines. We ‘put intelligence’ where it is required most, directly into our equipment, close to the mechanics."

Real-World Impact

At Mitsubishi HiTec Paper Europe GmbH, a monitoring system for cooling fans in a paper machine paid for itself in just one hour of production time. With daily production exceeding 300,000 kg, preventing even brief stoppages brings significant financial benefits. "Supply chain reliability starts on the factory floor," says Daniel Sperlich. "When a machine can self-diagnose before breaking down, it prevents the chain reaction of missed deliveries that can disrupt downstream operations."

The Predictive Future

The global predictive maintenance market, valued at $7.85 billion in 2022, is expected to grow at 29.5% yearly through 2030 (https://www.grandviewresearch.com/industry-analysis/predictive-maintenance-market) . “There is growing interest in implementing new maintenance systems step by step to optimise productivity. The idea here is that improvements can start at the machine level as well as the whole line or factory level so that automation is perfectly tailored to meet the specific needs of a particular production facility” - adds Daniel Sperlich. “In this way, the return on investment is also much easier to calculate and fully understand. At Mitsubishi Electric we call it the Smart Manufacturing Kaizen Level (SMKL) approach”.

The dynamic growth of the predictive maintenance market reflects the increasing need of manufacturing companies to shift from reactive to proactive strategies, enhancing performance whilst stabilising supply chains in uncertain times. A key driver is the ability to implement these solutions in a scalable manner – from individual devices to entire production facilities – without requiring significant initial capital investment and with clear and easy ROI calculation.

3D Ultrasound Sensor for Autonomous Robots

Promising alternative to LiDAR systems on track to receive SIL2/PL d safety certification

Norwegian deep-tech startup Sonair is presenting its safety-certified 3D ultrasound sensor ADAR to improve workplace safety in environments shared by humans and robots. ADAR enables full 360-degree 3D obstacle detection around autonomous mobile robots (AMRs). AMR manufacturers can use it to build safer and more affordable autonomous robots at significantly lower costs than with current sensor packages. Sonair’s patented ADAR (Acoustic Detection and Ranging) technology detects people and objects in 3D. A single ADAR sensor provides a complete field of view of 180 x 180 degrees and a detection range of five meters for the robot’s safety functions — like a virtual protective shield.

ADAR is developed according to ISO 13849:2023 Performance Level d / SIL2. Sonair aims to achieve full safety certification by the end of 2025.

Sensor technology validated

More than 20 global companies — including AMR manufacturers, industrial firms, automotive suppliers, and companies in healthcare and cleaning — have already validated the effectiveness of the ADAR sensor through an Early Access Program launched in summer 2024.

Commercial orders and confirmations are already in place. For example, Japan’s FUJI CORPORATION has selected ADAR for a future line of autonomous mobile robots.

“Sonair combines rapid development capabilities with a flexible mindset,” says Koji Kawaguchi, General Manager of the Innovation Promotion Department at FUJI CORPORATION. “Thanks to strong collaboration and extensive testing, we were able to confirm the sensor’s high suitability for autonomous mobile robots.”

What is ADAR?

Acoustic Detection and Ranging (ADAR), a patented innovation by Sonair, represents a new category of 3D depth sensors. It enables autonomous robots to achieve omnidirectional depth perception, allowing them to “hear” their surroundings in real time using airborne sound waves to interpret spatial information. “ADAR is an advanced plug-and-play sensing technology that supports compliance with safety standards. Thanks to its compact size and low power and compute requirements, it can be easily integrated into a combined sensor package,” explains Knut Sandven, Sonair CEO.”

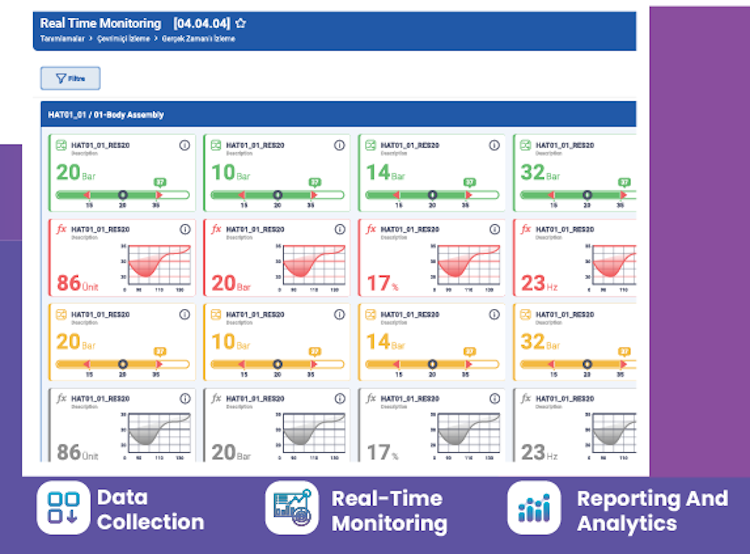

Real-Time Machine Monitoring Solution

Production data monitoring and analysis for effective, data-driven decisions

Automation

In the digital transformation, data is no longer just something to be observed; it is the most valuable asset for making decisions. Designed to optimise and streamline your production processes, Monitora by Siskon enables manufacturers to lead the digital transformation by making every stage of production traceable, analysable and manageable. By collecting real-time data from industrial machines and processes, Monitora enables businesses to instantly monitor production performance, detect deviations and identify areas for improvement. Its user-friendly interface and flexible architecture transform field data into actionable insights, supporting fast and effective decision-making.

Support for management and shop floor operators

Real-time data collection enables the tracking of all machines, stations and processes on the production line. Direct integration with PLCs and control systems from various brands is supported. Time- and event-based data records enable root cause analysis and performance comparisons, allowing recurring issues to be eliminated quickly. Trend analysis of process data can be used to optimise and proactively shape maintenance plans and quality strategies. Monitora seamlessly integrates with existing systems, eliminating the need for additional investments or lengthy implementation processes. Based on open, secure, and standards-compliant communication via OPC UA, the solution offers a web-based, multilingual user interface with live monitoring dashboards, as well as role-based user management and authorisation. Alarm tracking and management supports an email and SMS notification system. The robust analytical foundation, flexible integration capabilities and streamlined design deliver value to management and shop floor operators alike.

Maintenance 4.0: Data as an Early Warning System

Predictive maintenance prevents unplanned downtime. Fixed maintenance intervals, however, are preventive in nature, as true prediction requires real-time system status information and intelligent data evaluation. The Digital Twin Starter Kit from Bosch Digital Twin Industries and Pepperl+Fuchs offers an easy way to get started.

Automation, Industry 4.0, Sensor Technology

With conventional maintenance strategies, generous buffers are unavoidable. It is better to replace a bearing three months too early than one hour too late. Nevertheless, there is no guarantee that a critical element will not fail. Minimal assembly errors and unexpected impacts from external mechanical forces can trigger what you wanted to avoid at all costs: unplanned downtime and its costly consequences.

Sensors for Real-Time Monitoring

Intelligent, networked sensor systems can be used to monitor plant components that require maintenance in real time. For example, vibration sensors can detect vibration patterns that change under the influence of wear, increasing contamination, and other influences. The evaluation of the sensor data provides a detailed and up-to-date picture of the actual condition, including a data-based calculation of the expected remaining service life. This not only enables proactive maintenance, but also predictive maintenance.

In addition to the vibration patterns of shafts and bearings, many other parameters can be monitored using appropriate sensors. Temperature values and curves can also indicate mechanical changes; changes in pressure values allow early detection of leaks and sealing problems; flow measurement, in combination with other data, can provide information about the condition of pumps, valves, and piping systems.

Digital Twin for Precise Maintenance

The decisive factor now is the intelligent combination and evaluation of all relevant data. A digital twin makes this step particularly efficient, as it provides a virtual representation of the physical system in real time and with a high level of detail. With targeted implementation, it becomes the central basis for predictive maintenance. It is therefore often incorporated into new systems from the outset. However, if you also want to take advantage of its benefits in existing systems, there is no way around retrofitting.

The principle of "never change a running system" is a sum of financial, technical, and psychological factors. All three are taken into account in the Starter Kit concept from Bosch Digital Twin Industries and Pepperl+Fuchs. Its aim is to make the integration of a digital twin as simple and cost-effective as possible, including in existing systems. The user not only receives a complete package conceptually, but also physically: In a compact cardboard box, they will find a powerful 12 kHz vibration sensor that performs condition monitoring on a moving machine part, an ICE2 or ICE3 IO-Link master, and a BTC22 embedded PC from Pepperl+Fuchs.

Plug and Play

These components are simply installed according to the supplied wiring diagram and connected to the network. As soon as the power is switched on, the system configures itself. The vibration sensor transmits its measured values to the IO-Link master, which forwards them to the Box Thin Client BTC22 for pre-processing and aggregation. This fanless computer also acts as an edge gateway and is designed for robust industrial use.

After a short teach-in phase, it transmits the processed data to the so-called "Intelligence Core", Bosch's digital twin platform. The digital twin analyzes and processes the collected system data to create a clear status picture from which options for action can now be derived. A simulation model with the IAPM tool (Integrated Asset Performance Management) enables real-time analysis, which is based on established cloud platforms such as AWS or MS Azure and also uses machine learning algorithms and artificial intelligence.

Customization and Scaling

The data can also be called up on the dashboard in the browser. Existing and future mechanical problems are visualized in detailed 3-D models. The evaluation software calculates remaining running times and offers differentiated predictions of predictable failures. This makes it possible to plan maintenance based on the condition of the system and actual requirements. At the same time, the evaluation can be used to further optimize processes. If a threshold value is exceeded or a critical situation occurs, a corresponding notification can be sent as a push message by email, text message, and other communication tools to specified recipients.

As a modular system, the Digital Twin Starter Kit can be individually adapted to the requirements of the respective system and scaled up as needed. Experts from Bosch Digital Twin Industries and Pepperl+Fuchs support users with coordinated advice on custom-fit integration and upgrades in line with IIoT and Industry 4.0.

Stepper Motor Controller Module with Multi-Protocol Communication

The I/O module controls stepper motors with Modbus/TCP, Ethernet/IP, or PROFINET interface to host PC, PLC or PAC

Automation, Motors & Drives

Acromag now offers a stepper motor controller in their BusWorks® NT Series of Ethernet I/O modules. The new NT2710 module provides six pulse train/logic outputs, six encoder inputs, and four general-purpose digital I/O for motion control applications with stepper motor drivers. A wide variety of commands are supported to precisely control the stepper motor position, speed and direction. Linear, triangular, and trapezoidal S-Curve acceleration/deceleration profiling reduces mechanical stress for smoother movements. Programmable controllers (PLCs/PACs) interface with the NT2710 module using Modbus TCP/IP, EtherNet/IP, or PROFINET network protocols. An OPC UA server, MQTT client, and RESTful API are also provided to support Industrial Internet of Things (IIoT) applications.

Integrated DIN rail bus for up to 64 channels over one IP address

NTE Ethernet models provide dual RJ45 ports for network communication plus the stepper I/O control channels. NTX expansion modules add extra I/O channels to control more motors or axes. Three NTX modules can link to the NTE communication module through an integrated DIN rail bus interfacing up to 64 channels over a single Ethernet IP address. A variety of signal processing functions are available on other NT Series analogue and discrete I/O modules, which can be combined to monitor or control voltage, current and temperature signals. Applications include machining, packaging, positioning, dispensing, printing, and many other industrial manufacturing operations. Motion control functions can now be integrated with data acquisition, status monitoring, on/off control, predictive maintenance, energy management, and many other requirements.

The BusWorks NT2000 Series offers a broad variety of I/O signal processing options. Sixteen I/O configurations are available as either NTE Ethernet I/O or NTX expansion I/O models. Analog I/O models feature up to sixteen inputs or eight outputs for monitoring and controlling current or voltage signals. Discrete I/O models provide sixteen tandem input/output channels or six mechanical relays to sense or switch on/off and high/low logic levels. For temperature measurement, thermocouple and RTD input models support many sensor types and ranges.

Latency-Free Ethernet Couplers

Contactless transmission of up to 50 W power and data rates of up to 100 Mbit/s

Automation

Turck's NIC-Q86-ETH inductive Ethernet multiprotocol coupler is opening up the possible range of application fields for contactless power and data transmission. The coupler transmits up to 50 W of power as well as 100 Mbit/s full duplex latency-free (<1 µs) data in all Ethernet protocols. This makes the new system the ideal interface between moving components or mobile applications and machine parts for particularly high real-time, performance or data rate requirements, especially when they are connected via Turck's multiprotocol and EtherCAT I/O modules and controllers that operate automatically in Profinet, Ethernet/IP, Modbus TCP and EtherCAT networks. Turck continues to offer the compact and robust NIC couplers with IO-Link COM3 and 230.4 kbit/s for applications in the IO-Link environment and for up to 18 watts of power.

Transmission up to 10 mm distance

The Fast Startup function (ramp-up time: 450 ms) enables the coupler to be used optimally in applications with frequent tool changes or production processes with fast cycle times. The combination of IP65 protection, the maximum transmission distance of 10 mm and the independence of the transmitted Ethernet protocol makes the NIC an efficient solution for OEMs and users with changing system requirements. A coupler set consists of a primary and a secondary part (NICP/NICS-Q86-ETH). Both parts can also be dynamically coupled with any other primary or secondary parts.

Typical areas of application for the couplers are mobile load carriers, rotary indexing tables, rotating tools or mobile pick-to-light systems.

AI Camera for Collision Warning in Industrial Environments

Enhanced driving safety with AI camera for person detection

Automation, Vision & Identification

On construction sites with blind spots, a construction machine equipped with the ifm O3M AI 2D/3D intelligent sensor system can reverse more quickly. A municipal vehicle can stop reliably, even if the person crossing is difficult to detect. At airports or container terminals, the sensor system guides the positioning of a passenger boarding bridge or a container to within centimetres without risk of collision. The combination of the two technologies virtually eliminates the annoying false triggers that are almost inevitable with conventional 3D systems. The number of false alarms is significantly reduced. This is because the system can detect whether there is a person or a pile of earth in the vehicle’s path. The result is increased efficiency in the work process.

Improved results in a radius up to 25 meters

Such is achieved through the unique combination of a 3D PMD sensor and 2D AI camera in an embedded area monitoring system. System reliability is greatly enhanced by fusing data from two different types of sensors on a fully integrated and calibrated platform. AI analysis of the 2D camera data improves the quality of object detection, enabling it to distinguish between people and other obstacles. The new collision warning system works much better and more accurately than conventional solutions. The O3M AI smart sensor system uses the data from the 2D and 3D cameras to generate a video that displays the surroundings and simultaneously overlays information on the exact distances to all objects and people within a radius of up to 25 metres onto the image. The O3M AI can always tell whether emergency braking, a controlled stop or deceleration would be appropriate in a given situation.

The high-resolution digital Ethernet camera is equipped with a powerful processor with AI accelerator (NPU). This enables ultra-fast processing of the AI algorithms for person detection directly in the system. In addition to the Ethernet camera, a 3D PMD camera is integrated. It provides an accurate distance measurement to the object in every single pixel based on the PMD time-of-flight principle. Depth mapping from the 3D system and video from the Ethernet camera can be combined or used on their own, depending on the application.

Trained for industrial environments

The O3M AI’s person and obstacle detection has been optimised for mobile machines. The collision warning system can accurately distinguish between a distant obstacle and a person in close proximity, even if that person is lying on the ground, is wearing dark clothing or is difficult for conventional systems to detect due to larger tools or unusual posture. It works in both bright sunlight and twilight and has a maximum range of 25 metres with an accuracy of 10 centimetres.

The AI, hardware and software have been developed in Germany by ifm. A wide variety of people, equipment and work positions from the typical mobile machine work environment are included in the AI training examples. The result is a far greater gradation of possible alarms and warnings from the system. When it comes to striking the right balance between efficiency and safety, this is an important criterion.

The new combined sensor system for mobile machines is available in several versions.

Enhanced Connector To Simplify Direct PLC-to-Database Integration

Accelerated PLC integration without need for programming

Automation

Softing Industrial announces feature enhancements to its tManager product line, enabling seamless, bi-directional communication between Siemens PLCs and SQL databases. The latest update introduces symbol browsing capabilities for Siemens S7-1200 and S7-1500 controllers, significantly reducing integration time and eliminating the need for manual tag creation. The enhanced Siemens connector builds on Softing's proven tManager in-chassis connectivity platform and expands tManager ControlLogix and tManager IPC (Industrial PC) to support Siemens controllers in addition to Rockwell and Modbus PLCs. Users can now browse PLC symbols and SQL database fields directly, set up triggers and deploy industrial applications such as track and trace, quality monitoring, KPI dashboards and recipe downloads.

Symbol browsing speeds up project realization

Previously, Siemens integration required time-consuming, manual symbol setup. With this new functionality, browsing and mapping symbols from Siemens S7 1200 and 1500 controllers is now just as streamlined as it is with Rockwell PLCs. The update also maintains support for legacy symbol creation with Siemens S7 300, 400, 1200 and 1500 controllers, ensuring full backward compatibility for existing installations.

As manufacturers face increasing pressure to improve traceability, reduce errors and gain real-time insights from plant-floor data, legacy approaches like clipboard logging or custom-coded solutions often fall short. tManager addresses these challenges with a no-code, off-the-shelf solution that’s easy to deploy and maintain.

With robust in-chassis and IPC-based architecture, built-in fault tolerance, store-and-forward capabilities and scalable integration with multiple PLCs and databases, the solution offers a reliable and supportable path to digital transformation. It enables rapid implementation of high-value industrial use cases including KPI monitoring, high-speed sorting, recipe management and MES integration — without the complexity of OPC protocol translation or PC-based middleware.

Extending Process Control: How Edge Intelligence and Lifecycle Separation Enable Smarter, More Resilient Industrial Operations

Real-time handling of process data at its point of production is an integral aspect of tomorrow’s automation system, enabling a more resilient operating environment for plant owners. ABB’s Kim Fenrich, Global Product Marketing Manager - DCS Platform, explains how edge computing complements the functional separation of core operations from a parallel layer of digital applications for monitoring and performance optimization.

Automation

On the journey to greater efficiency, agility and sustainability, the process industries are being transformed by two distinct yet complementary technology trends. Together, they represent a new architectural approach that’s making control infrastructures smarter, safer, more autonomous, and more reliable. As key enablers for plant owners’ wider digitalization strategies, they’re also paving the way for a flexible, freely scalable automation future.

The first of these technological enablers is edge computing. An increasingly important element of today’s automation system and industrial producers’ wider digitalization strategies, edge computing brings real-time processing power, the hosting of applications and data storage closer to where they deliver the greatest value – at the point of data production. Enabled by technological advances in infrastructure, containerization, connectivity, and AI, edge affords a host of benefits in industrial automation environments. These include greater performance, faster response times, reduced latency and improved resilience, as well as more efficient use of available network resources and strengthened cybersecurity.

Rapid response, greater resilience

By enabling real-time data processing directly at the source, near sensors, actuators, and other devices, edge computing allows control and monitoring systems to respond quickly to changing conditions. By processing data locally, it avoids delays caused by sending information to distant servers or data centers, ensuring near-instantaneous responses for safety-critical and time-sensitive operations.

Processing data at the source significantly reduces the need for high-bandwidth connections and lowers the cost of transferring large volumes of data to cloud-based applications. Edge systems can also operate independently, providing resilience during network disruptions or cloud service outages. This makes edge computing especially valuable in remote industrial sites or mobile environments, where internet connectivity may be limited or unreliable.

Placing computing resources at the site where data is generated – such as a mine, offshore windfarm or oil platform – helps reduce cybersecurity risks associated with transmitting industrial facility data over public networks to remote data centers. While both private and public clouds offer strong built-in security, keeping commercially sensitive data on-site ensures it remains under direct control of plant operators, minimizing the risk of unauthorized access or data exfiltration. In addition, processing data locally allows faster containment of cyber threats. If one edge node is compromised, the impact can be isolated without affecting the broader network. This localized approach also helps organizations avoid potential legal or regulatory complications related to storing or processing sensitive data in other jurisdictions.

Responding to the voice of process industry end-users

Since its introduction in the 1970s, the Distributed Control System (DCS) has revolutionized industrial operations by improving efficiency, safety and reliability. While technology has evolved over the decades, its core purpose remains the same: reducing the need for constant human oversight in control and monitoring tasks.

During this time plant owners have faced growing challenges, from global competition and stricter safety regulations to rising cybersecurity threats. At the same time, they have been forced to adapt to meet rapidly changing customer demands which require flexible, scalable production systems capable of delivering customized products quickly. The pressure to produce more with less continues to intensify as the process industries respond to the demands of energy transition and decarbonization. Plants must become leaner, cleaner and more energy efficient, while minimizing waste and shifting to renewable power sources. Compounding these challenges are the realities of a changing workforce; where experienced engineers are retiring and being replaced by digital-native employees that lack the decades of ‘traditional’ and expert knowledge of their predecessors.

By accelerating decision-making and supporting a more responsive, resilient control paradigm that can integrate new capabilities without disrupting existing operations, edge computing addresses these challenges by offering plant owners a powerful way to maximize the value of their process data.

Re-appraising the decades-old automation paradigm

From an automation standpoint, industry’s ongoing push toward digitalization is driving the convergence of operational technology (OT) and information technology (IT). This integration enables the deployment of value-added digital applications that can reside either on-premises or in the cloud. For existing facilities, it’s essential that these new automation capabilities be introduced with minimal disruption to current processes and operations.

In response to growing demands from process industry customers for greater efficiency, flexibility, interoperability, security, and sustainability, there is a fundamental rethinking of long-standing automation system models. Plant owners are seeking to modernize and future-proof their operations while maintaining continuity and minimizing production downtime.

Building on decades of experience delivering process control solutions worldwide, ABB’s response to these evolving needs is an automation system that embraces advances in digital technology while preserving the ultra-reliable performance industrial users depend on.

Towards modularization and a separation of concerns

ABB’s vision for a future-proofed automation system centers on providing a separation of concerns; two distinct but interconnected software environments designed to balance reliability with innovation. This division supports dependable, real-time process operations while enabling open access to process and equipment data for monitoring and optimization.

These environments – termed the control and digital environments – provide a modular, scalable architecture that encourages innovation by simplifying the introduction of new technologies and services to meet evolving operations demands.

The control environment forms a robust, cyber-secure foundation for executing critical automation functions. It includes the physical hardware, software configurations, and network infrastructure required to ensure deterministic, real-time control of industrial processes. Crucially, it leverages edge computing to process and store data locally, allowing for immediate responses to operational changes.

Operating alongside this is the digital environment, which provides secure access to process data for higher-level Monitoring and Optimization (M&O) applications. Hosted either on-premises or in the cloud, these applications can analyze performance, predict maintenance needs and drive efficiency improvements without interfering with core control functions. This digital layer also acts as a sandbox for deploying emerging technologies, such as AI-powered analytics, incrementally and safely via software-defined methods, avoiding costly plant shutdowns or disruptions.

This dual-environment architecture reflects industry’s broader shift toward digitalization, where operational and informational technologies (OT and IT) converge to unlock new automation possibilities. For existing installations, it’s essential that these innovations be integrated with minimal disruption to ongoing operations.

A vision for smarter, more resilient industrial operations

In response to growing demands for efficiency, flexibility, interoperability, security, and sustainability, process industries are rethinking traditional automation models. Plant owners seek to modernize and future-proof their systems while maintaining continuity and control.

ABB’s vision of an automation ecosystem addresses these needs by embracing advances in cloud native technology and connectivity, without compromising the ultra-reliable performance that industrial users expect. Built on decades of experience, this approach enables seamless integration of new capabilities while preserving the integrity of core operations. The commitment to continuity allows process industry users to meet today’s challenges, including sustainability, energy transition and a new generation workforce, while adapting to evolving market opportunities.

How Electromechanical Actuation is Making Electric Flight a Reality

Whether you’re talking about hybrid regional jets to next-generation air taxis it’s increasingly clear that the future of flight is electric, and electromechanical (EM) actuation is playing a central role in making this a reality. As aircraft systems move away from hydraulics and pneumatics in favor of all-electric architectures.

Motors & Drives

EM actuation is enabling lighter, more modular designs that promise greater efficiency, simplified maintenance, and a clearer path to certification.Whether you’re talking about hybrid regional jets to next-generation air taxis it’s increasingly clear that the future of flight is electric, and electromechanical (EM) actuation is playing a central role in making this a reality. As aircraft systems move away from hydraulics and pneumatics in favor of all-electric architectures, EM actuation is enabling lighter, more modular designs that promise greater efficiency, simplified maintenance, and a clearer path to certification.

Regal Rexnord Aerospace Solutions is helping to advance the adoption of electro-mechanical actuation by delivering integrated subsystems that combine high-performance motors, gearing, brakes, and control systems. Drawing on the industry expertise of its brands, including Rexnord Aerospace, Kollmorgen™, Portescap™, Nook™, and Delavan™, Formsprag Clutch, Thomson, the company is helping to support a wide range of aerospace applications through a unified, system-level approach.

The shift to all-electric

For decades, hydraulic systems have delivered the motion needed for flight control, landing gear, and high-lift systems. But as new aerospace platforms emerge, the drawbacks of hydraulics, such as complex plumbing, weight penalties, and intensive maintenance, are becoming more apparent.

That’s where EM Actuation comes in. By replacing traditional hydraulic systems with compact, electrically driven actuators, aircraft designers can reduce weight, simplify architectures, and increase system flexibility. The result is faster assembly, superior control, and improved reliability.

"We’re seeing a clear shift toward fully electric fly-by-wire systems, particularly in emerging platforms like eVTOLs and uncrewed aircraft," explains John Meyer, Senior Director Marketing at Regal Rexnord. "EM Actuation offers a streamlined alternative with real benefits in integration, efficiency, and performance."

Unlocking the aircraft of tomorrow

Modern EM Actuation systems are far more than a simple motor and gearbox. To meet aerospace demands, they must be precision engineered for high reliability, minimal weight, and exceptional control responsiveness. This calls for a coordinated approach where every element – motors, gearing, sensors, and brakes – is designed to work together as a complete system.

“In most of the programs we support, the actuator isn't something pulled directly from a catalogue,” notes Julian Del Campo, Senior Business Development Manager at Regal Rexnord. “It’s a tightly integrated system that tailors proven designs to the envelope, load, and responsiveness required for that airframe. That’s where the value of early engineering collaboration really shines.”

This is exactly why EM actuation suppliers should be deeply involved with design projects from day one, helping OEMs and system designers explore trade-offs between actuator size, power consumption, and redundancy strategies. A collaborative process like this accelerates development and supports a smooth path to compliance – both key factors as aerospace innovation accelerates and compresses timelines.

Programs that once spanned a decade now aim for certification in a fraction of that time. The emerging advanced air mobility (AAM) sector is a clear example, with developers working to deliver electric aircraft to market on ambitious schedules. That’s adding extreme emphasis on agility and scalability, as EM actuation systems must not only meet performance targets but do so within short, iterative development cycles. Suppliers need to offer rapid prototyping, customizable solutions, and deep familiarity with aerospace standards.

“Being able to take a proven aerospace motor or resolver design and adapt it quickly to a new platform is a huge advantage,” says Julian. “It reduces risk and shortens the path to flight qualification. That’s critical when every moment counts.”

From innovation to integration

As the boundaries of EM Actuation expand, the technology is reaching into new areas of the aircraft. In the future, electric actuation is expected to play a role not just in secondary functions but also in primary flight controls, landing systems, and high-lift devices, even in large commercial aircraft.

This evolution is already underway, and it underscores the need for systems that are not only robust but also easy to integrate. EM Actuation solutions must deliver precision control, environmental durability, and fault tolerance, all while fitting into the tight weight and space constraints of modern aircraft.

At the same time, developers are seeking out partners who can support them with more than just components. Regal Rexnord’s motion control brands offer decades of aerospace experience, along with a proven track record of collaboration across a broad spectrum of air and defense platforms.

Robust, Compact Cycloidal Gears for Heavy-Duty Applications

For precision positioning of heavy loads

Motors & Drives

Heavy loads are often moved by means of hydraulic systems or large planetary gears. However, cycloidal gears are clearly superior in most cases. Their special design principle enables very high reduction ratios with only two to three gear stages, which guarantees precise and reliable positioning within a hundredth of a millimetre in an extremely compact design. Nabtesco knows the specific challenges of heavy-duty applications and implements robust and efficient gear and drive solutions.

Robust cycloidal gears for precise positioning of heavy loads

Cycloidal gears use cams and rollers for power transmission. This design ensures virtually full contact and even distribution of forces within the gearbox, which produces high rigidity. As a result, it is possible to transmit very high torques with maximum precision and smooth operation. The increase in backlash is infinitesimal, even over long periods (hysteresis loss < 1 arcmin, purely mechanical backlash 0.1 - 0.2 arcmin). In addition, minimum wear operation ensures a long service life. The integrated angular ball bearings absorb both axial and radial loads and bending moments, and provide for high moment rigidity and resistance to impacts and overloading (up to 500 % of the rated torque). By the way: In cycloidal gears, the efficiency improves as the load increases. The reason: Higher torque results in higher rigidity. Rigidity reduces elasticity in the gear, which causes an increase in efficiency.

Exceptional performance up to 70,000 Nm

Whether in robotics, mechanical engineering or other high-tech industries: Wherever exact positioning and absolute reliability are required, Nabtesco gears are the first choice. The product portfolio ranges from highly integrable component sets, compact gear units, and dynamic servo gearboxes to powerful rotary indexers and covers a torque spectrum up to 70,000 Nm. The following parts of the portfolio are especially suitable for use in heavy-duty applications: Neco®HT (modular high-torque gears), RV-N (solid shaft robotic gears), RV-C (hollow shaft robotic gears) and RS (hollow shaft rotary indexers). The product range also includes the world’s largest precision gearbox (RV-2800N) and the world’s largest plug-and-play precision gearbox (Neco® HT-900).

Wide range of heavy-duty applications

Nabtesco cycloidal gears are designed for high torques and heavy loads and have proven themselves a million times over in countless heavy-duty applications. Heavy-duty positioners (large head and tailstock positioners, “L” and “H” positioners) benefit from the specific properties of the heavy-duty solutions, as do machine tools (e.g. machining centres for large gearwheels, feeder systems for large, heavy parts, tower drilling centres for wind turbines), production plants (such as “big wheel” refrigerator production, extrusion blow-moulding machines) and industrial automation (handling of large glass panes, metal sheets, heavy machine parts, or entire vehicles).

Highest service level

In cooperation with the customer the company implements custom drive solutions that are perfectly adapted to the particular challenge. The cycloidal gear specialist offers full-service support and assistance with all aspects of gears and drive systems – from initial consultation to selection and design, as well as production and maintenance.

SIL3 Approved PROFIsafe Encoder

Functionally safe, reliable performance in the toughest industrial environments

Leine Linde is proud to launch a comprehensive new safety range alongside the cutting-edge FSI 600 series. The series is a family of safety-certified rotary encoders, engineered to meet the highest functional safety standards. With this initiative, Leine Linde enables industrial players to enhance workplace safety while meeting growing global regulatory demands. As safety requirements in industrial automation continue to rise, so does the need for certified, high-performance safety products. Leine Linde’s new solution delivers on both – helping leading manufacturers protect people, machinery and production environments worldwide.

Certified for the most demanding applications

The FSI (Functional Safety Integrated) 600 series marks a significant step forward in Leine Linde’s portfolio. With its SIL3 and PLe category 4, functional safety compliance it is certified for use in the most demanding safety applications. The absolute inductive sensing offers a durable, contactless technology for long-term reliability in harsh environments. PROFIsafe over PROFINET ensures safe communication in real-time industrial networks.

The first product in the FSI 600 series, FSI 608, is a unique safety encoder that fully complies with the latest standard: IEC 61800-5-3, covering functional, electrical and environmental encoder safety. FSI 608 is among the first encoders on the market to meet this level. With multiple mechanical options, scalable resolution and comprehensive built-in safety functions, the FSI 608 offers easy integration into diverse automation setups.

NORD has increased the maximum torques of its UNICASE worm gear units. The NORD development team thus achieved increased performance of 10 to 15 percent – without changing the gear units’ outer (connection) dimensions, or their general outer appearance. The reliable and economic drive solution offers higher performance without the need of adjusting existing customer configurations. As the housing sizes remain unchanged, the worm gear units will still be available as a drop-in solution for maintenance works or repairs. To save costs and installation space, smaller sizes can be selected according to the application, resulting in more constructive freedom in machine and system design.

High-skilled engineering

The (connection) dimensions have not changed, but in order to implement higher power ranges, NORD incorporated new worm shafts with larger bearing seats, as well as an additional reinforcement of the worm wheel itself. The current UNICASE worm gear unit series offers a power range from 0.12 kW to 15 kW, and torques between 90 Nm and 3,000 Nm. Other product advantages include smooth and quiet running, high overload capacity and robust design. High axial and radial loads ensure high (operational) reliability and long service life.

The UNICASE worm gear units in cast iron housings from NORD are available in application-specific versions: as hollow and solid shaft gear units, and for shaft, flange or foot mounting. The company’s electric motors can be added as an integrated solution. Motor mounting via an IEC/NEMA adapter is also possible.

New Connector Contact Plating

Surface plating reduces the amount of precious metal needed for reliable connections

Electronics & Electricity

TE Connectivity (TE) is introducing a breakthrough connector contact plating technology: The ECONIDUR surface plating is designed to reduce traditional precious metal layers in contact surfaces and helps to significantly lower CO2 emissions while maintaining uncompromised quality standards. The name ECONIDUR mirrors the advantages of this nickel-phosphorous based plating: the contact finish is more ECOlogically friendly due to having a lower product carbon footprint, based on the NIckel-phosporous plating stack excellent performance in DURability is conserved. The high-performance ECONIDUR plated contacts solution supports engineers with superior vibration resistance and reliability for demanding applications. Recently developed measurement methods help to ensure high quality in process and product reliability.

Meeting increasing customer requirements

Whether it is high signal integrity or high vibration resistance, customer expectations have risen significantly. In most industrial applications, improved protection against vibration, fretting and corrosion is essential. This is why choosing the right plating is so important today. ECONIDUR plated connectors will function reliably in many industrial applications over a long period of time, e.g. in automation control applications and motor control systems. They support reliable signal transmission up to several Gbit/s and feature withstand capabilities in terms of vibration in the long-term, gas influences and micro friction.

Sophisticated stack configuration

The key to this high quality and outstanding performance is the layer structure: ECONIDUR contacts are plated with a skillfully engineered Nickel-Phosphorus plating (NiP) that utilizes a sophisticated stack configuration.

Overall, ECONIDUR plating reaches in minimum the same characteristics as a precious metal plating layer. For fretting and vibration resistance, ECONIDUR plated products are a reliable choice. According to TE internal analysis and calculations in alignment with ISO standards (14067/14040/44), CO2 emissions decrease heavily for over 44% compared to a precious metal plating, depending on layer thicknesses, performance level and connector type – thus contributing to greener manufacturing and supply chains. This decarbonized product helps customers meet their sustainability goals.

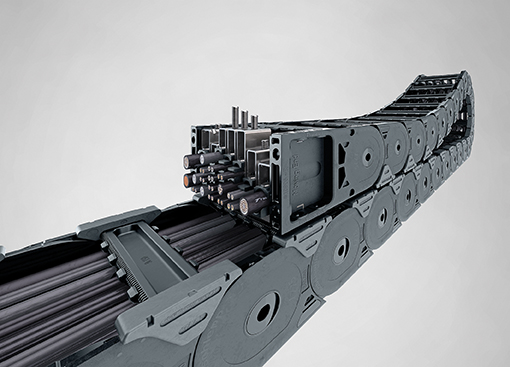

Modular Cable Carrier for Modern Machine Solutions

Robust, flexible and easy to assemble for a wide application range

Electronics & Electricity

The Tsubaki Kabelschlepp UNIFLEX Advanced 1775 has recently been significantly enhanced – not just in the details, but also in its variants. New width options between 100 and 400 mm and different frame variants (closed or with folding crossbars inside or outside) turn the cable carrier into a universal solution for a wide range of applications, from the automotive industry and machine tool manufacturing to agricultural technology and intralogistics.

The UA1775 also offers practical advantages from an assembly point of view: The crossbars can be opened and closed in just two easy steps. A simple screwdriver is the only tool required. Should a crossbar stay open, it is still firmly attached to the chain link. If needed, the crossbars can easily be released with a simple twisting motion.

Quiet, durable, smooth

The four-part chain link design ensures quiet running while also saving storage space: Fewer parts, many options – that is the essence of the modular solution. Combining the cable carrier with the TS3 divider system opens up new application scenarios, for example for extended travel lengths or tight spaces. Particularly worth mentioning: The cable carrier is made with up to 35 % regranulate – a relevant aspect also in light of the increasing requirements for sustainability.

A modular system for the future

The UA1775 series is part of the modular UNIFLEX Advanced system. It can be supplemented with a variety of accessories: from robust standard guide channels made of steel or aluminum and universal end connectors to condition monitoring components. Complete system solutions – the TOTALTRAX® concepts – can also be implemented with these cable carriers.

Board-Mount EMI Filters

Differential mode filtering for switching power supplies with high input current requirements

Electronics & Electricity

TDK Lambda introduces the new RGF board-mount EMI filters. Suitable for power supplies with high input current requirements, these 20 and 40A filters are designed to provide exceptional differential mode filtering. Leveraging advanced TDK component technology, these modules streamline system-level compliance to CISPR as well as other compliance standards.The RGF filters are encapsulated for protection in harsh environments, measure 52.8 x 35.2 x 12.7mm in size, and feature a robust 5-sided metal case. The design includes two threaded and two non-threaded mounting holes, ensuring easy installation and enhanced cooling in both conduction and convection-cooled systems. Applications include harsh industrial, commercial-off-the-shelf (COTS), test and measurement, communications, broadcast, and robotics.

Input voltage range from 0 to 80V

When used in conjunction with non-isolated DC-DC converter modules, the filters provide a significant amount of differential mode attenuation over a broad frequency range. This reduces overall system noise and simplifies compliance to typical EMI standards. The input voltage ranges from 0 to 80V and withstands input transients of up to 100V for 100ms durations. The operating case temperature is between -40 to +120°C, with a qualified Thermal Cycling Test (TCT) of 700 cycles, or -40 to +125°C with a 60°C/minute ramp, and a 30minute dwell time. The RGF filters are compliant to MIL-STD-810G 516.6 Procedure I & IV for shock and MIL-STD-810G 514.6 Procedure I, Cat 10 for vibration.

Enclosure Concept for Outdoor Use

Innovative design for wireless, embedded and instrumentation systems

Electronics & Electricity

The innovative and advanced BoVersa enclosure concept from specialist manufacturer BOPLA offers customers an innovative modern design suitable for a wide range of applications. Flexible and customer-specific design options include a lighting concept, wireless communication and maximised cooling technology.

Application-specific combinations

For wireless systems a die-cast aluminium enclosure body with moulded-in cooling fins can be combined with a plastic cover, allowing unhindered radio transmission while providing an optimal combination for wireless applications that require cooling. For efficient heat dissipation, BoVersa has integrated cooling fins into the die-cast aluminium enclosure. The point-symmetrical design of the fins optimises airflow and ensures cooling of the enclosure when mounted horizontally or vertically. The uniform airflow maximises the efficiency of cooling and provides even and stable temperature distribution in the enclosure, increasing the service life and reliability of the built-in electronics.

BoVersa has a three-part enclosure structure consisting of a lower part, a functional lid and design cover which can be combined with each other as required. Colour accents can be added by combining enclosure parts in different colours to suit an application or branding requirement.

Features of the new BoVersa enclosure system also include transparent function lid providing a view inside the enclosure or built-in displays and open versions for integration of keyboards and displays.