Quick access

Contents2 Industry News: EPC - Renesas | Advantech - AI EdgeLabs3 Industry News: Hannover Messe | Rohde & Schwarz4 Industry News: WIKA - Asystom | Alfa Laval5 Industry News: Softing Industrial - INSYS Icom | European Chip Skills Academy6 GL Events (Advertisement)7 Automation Extended: Unlocking Industry’s Full Potential8 Automation: TRIO Motion | MCS Group9 Automation: JUMO | Beckhoff Automation10 Reducing Maintenance by Removing Mechanical Motion11 Sensors, Test & Measurement: ifm | EBE sensors + motion12 Empowering Humanoid Robots13 Motors & Drives: Apex Dynamics | Stabilus14 Motors & Drives: Gamak | Kollmorgen15 Motors & Drives: Toshiba | ABB IEC Motors16 Electronics & Electricity: Phoenix Contact | TDK Lambda17 Electronics & Electricity: Traco Electronic | Schurter | Sensata18 Index19 Contacts20Companies in this issue

JUMO GmbH & Co. KG10 Portescap S.A.13 SCHURTER AG18 Traco Electronic AG18ABB IEC Low Voltage Motors16 ABB Process Automation8 Apex Dynamics UK Ltd14 Beckhoff Automation GmbH10 Gamak Makina Sanayi A.S.15 GL Events Exhibitions Industrie7 JUMO GmbH & Co. KG10 Kollmorgen Europe GmbH15 MCS Group9 Phoenix Contact GmbH & Co. KG17 Portescap S.A.13 SCHURTER AG18 Sensata Technologies Holland B.V.18 Stabilus GmbH14 TDK-LAMBDA Germany GmbH17 Toshiba Electronics Europe GmbH16

#2 Contents

#3 Industry News: EPC - Renesas | Advantech - AI EdgeLabs

#4 Industry News: Hannover Messe | Rohde & Schwarz

#5 Industry News: WIKA - Asystom | Alfa Laval

#6 Industry News: Softing Industrial - INSYS Icom | European Chip Skills Academy

#7 GL Events (Advertisement)

#8 Automation Extended: Unlocking Industry’s Full Potential

#9 Automation: TRIO Motion | MCS Group

#10 Automation: JUMO | Beckhoff Automation

#11 Reducing Maintenance by Removing Mechanical Motion

#12 Sensors, Test & Measurement: ifm | EBE sensors + motion

#13 Empowering Humanoid Robots

#14 Motors & Drives: Apex Dynamics | Stabilus

#15 Motors & Drives: Gamak | Kollmorgen

#16 Motors & Drives: Toshiba | ABB IEC Motors

#17 Electronics & Electricity: Phoenix Contact | TDK Lambda

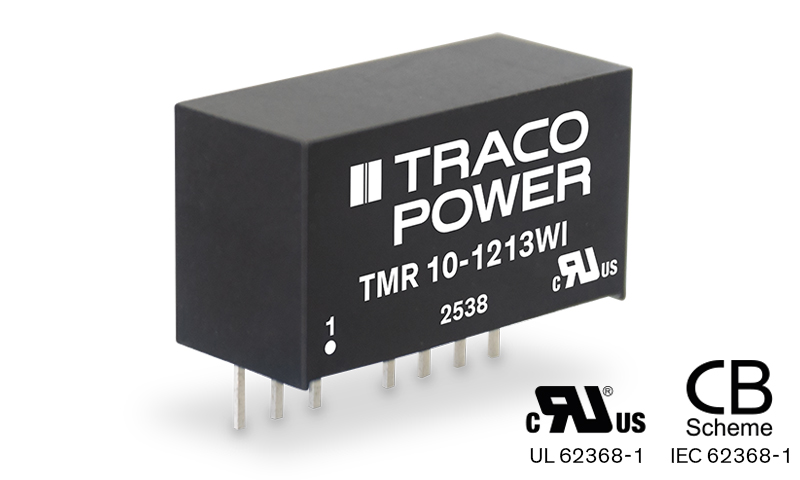

#18 Electronics & Electricity: Traco Electronic | Schurter | Sensata

#19 Index

#20 Contacts

EPC Announces Strategic GaN Technology Agreement with Renesas

EPC's GaN technology strengthens Renesas' market presence in high-volume consumer and AI power.

Under the comprehensive licensing agreement, Renesas will gain access to EPC’s proven low-voltage eGaN (enhancement mode gallium nitride) technology and its established supply-chain ecosystem, accelerating the adoption of high-performance GaN solutions across a broad range of markets. EPC and Renesas will collaborate over the next year to establish internal wafer fabrication capabilities for these products. In addition, Renesas will second-source several of EPC’s popular GaN devices that are already in mass production, enhancing supply-chain resilience for customers.

Broader access to GaN technology for customers

As power electronics designers push for higher efficiency, greater power density, and lower carbon footprints, the physical limits of silicon increasingly constrain performance and miniaturization. Compared with silicon, GaN transistors offer higher efficiency, faster switching speeds, and significantly smaller form factors. These advantages are reshaping power conversion architectures across applications ranging from consumer electronics to AI data centers. This alliance expands customer access to GaN technology while providing increased supply assurance through qualified second sourcing.

“Together, EPC and Renesas are forming a global alliance to deliver state-of-the-art power efficiency - cutting costs in AI data centers and enhancing autonomous systems. This is an exciting moment for our industry and our company,” said Alex Lidow, CEO of EPC.

“Expanding our business into low voltage GaN allows us to serve the fastest growing power segments,” said Rohan Samsi, VP, GaN Business Division at Renesas. “This agreement with EPC complements our established high-voltage 650V+ portfolio and enables us to capitalize on high-volume markets such as AI power architectures from 48V down to 12V and 1V, as well as client computing and battery-operated applications.”

Advantech Announces Software Partnership on Cybersecurity

AI EdgeLabs selected as Primary Runtime Security and Governance Platform for Edge and Industrial Systems

Advantech announced the partnership with AI EdgeLabs, the pioneer in AI-native extended runtime security and governance platform for distributed mission-critical workloads and infrastructure. The partnership reinforces Advantech’s commitment to industrial cybersecurity and supports customer readiness for evolving European cybersecurity requirements, including the Cyber Resilience Act (CRA) and NIS2.

Distributed Edge / IOT operational technology (OT) environments play a critical role in manufacturing, transportation, energy, and other essential industrial sectors. As these systems become increasingly connected, they face heightened cyber risks while also falling under stricter regulatory oversight. European cybersecurity regulations are placing new mandatory obligations on system operators and product vendors, requiring continuous risk management, runtime protection, and demonstrable security controls throughout the system lifecycle.

Reducing the need for third-party tool integration

Advantech already implements secure development and hardware practices aligned with IEC 62443 standards. By integrating AI EdgeLabs’ runtime & governance layer, Advantech enables enforcement of CRA and NIS 2 compliance for their partners and end clients.

“With AI EdgeLabs designated as its primary runtime security solution, Advantech will embed compliance-ready security capabilities across selected edge and industrial platforms, reducing the need for customers to integrate additional third-party security tools to meet regulatory obligations. This a strategic move for us” said Alicja Strzemieczna, Sales Director Manufacturing and Infrastructure Sector at Advantech Europe.

“Regulations like CRA and NIS2 require security controls that operate continuously, not just at design or deployment time,” said Inna Ushakova, CEO at AI EdgeLabs. “Working with Advantech allows us to bring runtime security and compliance capabilities directly into industrial and edge platforms used in critical environments.”

Application Park with Robotics Innovations at HANNOVER MESSE

The latest trends in robotics can be experienced at HANNOVER MESSE 2026 from April 20 to 24.

The focus at this area of the fair will be on AI-based perception systems, autonomous mobile manipulators, and humanoid robots. Their advantage over classic industrial robots lies less in their pure performance and more in their adaptability: they are designed to use tools, workstations, and infrastructures developed by people. This enables processes to be automated or modifications made to established procedures and products without having to rebuild the entire production environment. In the classic fields of automation such as automotive or electronics production, specialized industrial robots with greater accuracy, speed, payload, and reliability will continue to occupy the high ground for the time being. Many advances on the software side are also expected in the field of robotics. In addition to improved digital twins through data-driven methods, aspects such as simulation and virtual commissioning are becoming more prominent as a means for programming or teaching robots more quickly – without interrupting production.

Among the exhibitors in the Application Park are:

Duatic AG from Switzerland will be among the exhibiting companies. The company is showcasing a versatile, vision-enabled semi-humanoid robot designed for dynamic manipulation and autonomous navigation. It offers advanced dexterity and precise movement, e.g. in intralogistics. Duatic's human-sized mobile dual-arm robots are tailored to industrial requirements, and are characterized by a unique modular architecture that enables easy maintenance and low operating costs. The robots are designed for heavy-duty cycles and offer high payloads and long operating times without requiring any changes to the infrastructure.

Hexagon, well-known for the activities in measurement technologies, will be presenting its AEON humanoid robot at HANNOVER MESSE. AEON combines sensors from Hexagon with advanced mobility, AI-driven mission control, and spatial intelligence to deliver agility, versatility, and perception. This combination enables AEON to be used for a wide range of industrial applications: from picking up specific objects and scanning industrial components for inspection purposes to creating digital twins. Thanks to a battery change mechanism that takes just 25 seconds, AEON does not need to be recharged to continue working.

Innok Robotics will be showcasing the new INDUROS family (350s, 700, 700s, 1300) at HANNOVER MESSE 2026. Innok thus offers a clearly graduated AMR portfolio – the right AI-supported transport robot for every material flow up to the 1.3 metric tonne class. The trade fair highlight in the Application Park in Hall 26 will be the new fleet manager in the Innok autonomy platform, Innok Cockpit for centralized planning, control and optimization of complete Innok robot fleets.

Techman Robot, a global leader in collaborative robots (cobots), will unveil its "AI Vision Flying Trigger" system at HANNOVER MESSE. Deeply integrated with the NVIDIA Omniverse platform, this cutting-edge solution underscores Techman Robot’s leadership in AI robotics and delivers a revolutionary smart manufacturing solution tailored to the European market’s dual demands for zero defects and high efficiency. The highlight of Techman Robot's showcase is the practical application of Digital Twin technology. The system allows for the precise simulation and optimization of the robot's high-speed motion paths and AI vision algorithms in a virtual environment before physical deployment.

If you want to meet the specialists at HANNOVER MESSE, you can register for a free ticket on the fair website: https://www.hannovermesse.de/en/application/registration/direct-entry-tickets-passes?code=OnhAp

Demystifying EMC 2026 Virtual Conference Hosted by Rohde & Schwarz

The annual virtual conference Demystifying EMC (DEMC) 2026, hosted by Rohde & Schwarz and partners, will take place over two half days on February 10 and 11, 2026.

Rohde & Schwarz invites the global EMC community to its virtual conference Demystifying EMC 2026, focusing on new regulations, emerging test methods, and faster, more efficient EMC testing. Interactive sessions will provide practical, step-by-step demonstrations.

Keynote: Navigating EMC testing in the age of AI and 6G

Arthi Krishnamurthy, EMC Segment Manager at Rohde & Schwarz, will highlight how AI, 6G, and advanced materials demand higher‑frequency testing, updated standards, and more efficient test methods to future‑proof EMC practices.

The conference will cover updates to CISPR standards for emissions above 1 GHz, Draft CISPR 32 Edition 3 proposals, APD weighting techniques, reverberation chamber testing, and fundamentals of conducted RF immunity per IEC 61000‑4‑6. Additional sessions include automotive EMC in reverberation chambers, high‑frequency GaN‑FET measurements, and EMC compliance for UAVs. Accelerating EMI testing DEMC 2026 will show how optimized setups and modern receivers reduce test time, introduce techniques like the Vibrating Intrinsic Reverberation Chamber (VIRC), and present results for a new antenna design supporting radiated EMI testing up to 44 GHz.

Interactive sessions

Hands‑on webinars will guide attendees through EMC measurement preparation, including an EMI debugging demo on a digital‑display coffee machine and a session clarifying misconceptions in transient immunity testing (IEC 61000‑4‑X).

More information on the event, speakers and registration can be found here: https://www.rohde-schwarz.com/demc/

WIKA Aquires Majority of Asystom Shares to Strengthen its IIoT Portfolio

Asystom SAS, a French company specialising in industrial smart monitoring and predictive maintenance solutions is now a part of the WIKA Group.

The measurement technology manufacturer and IIoT solution provider WIKA has held a stake in Asystom since 2024. As the majority shareholder, WIKA now intends to play an even more active role in shaping the company’s strategic direction. The global network of WIKA subsidiaries is to strengthen the sales and servicing of the Asystom solutions – for example for installation. WIKA will also use its research and development resources to collaborate with Asystom on the continuous development of its portfolio.

Asystom develops advanced sensors and intelligent solutions for the remote monitoring of industrial systems. The company’s core offering is based on embedded acoustic and vibration data processing technologies, combined with AI-driven analytics and diagnostic tools that enable continuous machine health monitoring. Multisensor instruments support signal acquisition, while the IIoT software layer analyses the data and detects deviations using machine learning. This enables companies in the process and manufacturing industries to identify anomalies at an early stage and perform targeted maintenance on their systems. Users can therefore avoid costly failures and organise their maintenance processes much more efficiently.

“WIKA sees itself as a driver for the development of pioneering IIoT technologies,” says Thomas Hasenoehrl, WIKA’s Vice President IIoT Systems & Solutions. “The majority stake in Asystom is another strategic milestone in this regard. The IIoT offers enormous optimisation potential for the industry, particularly in the field of predictive maintenance. With its innovative, scalable solution, Asystom complements our partner network perfectly.”

Pierre Naccache, Asystom’s CEO, says: “Industrial players need solutions that stand the test of time. With WIKA, we combine global deployment capabilities and a shared technology vision to deliver a complete, integrable and scalable approach that brings together sensors, connectivity, software and services, addressing industrial needs in the short, medium and long term. Our ambition goes beyond predictive maintenance alone: we want to provide an open and future-proof foundation for collecting, processing and turning industrial sensor data into actionable value at scale.”

Closing the Loop on Plastic Waste

Alfa Laval is turning circularity into action with the launch of ThinkCircularity, a take-back programme that recycles materials from its ThinkTop valve control units. The pilot project has been well received by customers and partners

ThinkCircularity initially focuses on plastic recycling. Each ThinkTop contains 500 grams of plastic, and the pilot project has demonstrated that this material can be recycled to produce new units without compromising quality. Tests confirm that the mix of reused and virgin plastic in future units meets all performance standards – from tensile strength to durability.

Furthermore, other materials and components from the ThinkTops – such as valuable metals and electronics – are responsibly recycled.

”Circular thinking is not just a buzzword for us – it is a responsibility,” says Inger Bygum, Head of Sustainability at Alfa Laval Hygienic Fluid Handling and Heat Transfer Technologies. “With ThinkCircularity, we ensure that materials from old ThinkTops can be reused, recycled or disposed of in the most responsible and value-creating manner.”

First units returned

In food, dairy and pharma industries, there is an ongoing focus on process optimization and resource savings. For instance, by upgrading their existing ThinkTop control units, which can save 90% on water and energy used for cleaning-in-place. This is also the case in Norway, where Skala, the Alfa Laval Master Distributor, specializes in servicing hygienic industries. They recently introduced the ThinkCircularity take-back scheme to their customers and have already sent back several hundred units.

“Our customers care about water and energy efficiency – and sustainability,” says Owe Barsten, Responsible Manager at Skala Components. “Upgrades mean that older units are scrapped, but now we can offer a truly circular solution where old ThinkTops give life to the next generation.”

First step in a broader circularity strategy

Key elements in Alfa Laval’s circularity strategy include designing products for durability, high efficiency and long lifetime. With ThinkCircularity, the company now closes the loop by offering an end-of-life solution that ensures that old products are scrapped responsibly and new products in the future can be made from recycled plastic. Inger Bygum emphasizes that this pilot project is only the start:

“Recycling plastic from old ThinkTops is just a small drop in a vast ocean of circular opportunities. Still, this pilot project is important to us and has taught us valuable lessons that will help us develop new business models, partnerships and methods to scale reuse and recycling.”

So far, the ThinkCircularity initiative has been launched in selected European countries.

Softing Industrial Becomes Certified Partner of INSYS Icom

The strategic partnership expands Softing Industrial’s portfolio for secure industrial networking, VPN-based remote access, and OT/IT integration in Industry 4.0 and Industrial IoT applications.

Softing Industrial is now a certified partner of INSYS icom, succeeding DELTA LOGIC Automatisierungstechnik GmbH, which was acquired by Softing Industrial in April 2025. The partnership brings together two areas of expertise that complement each other perfectly: For more than 40 years, Softing Industrial has stood for modern connectivity solutions in industrial automation and professional OT/IT data integration. Its products ensure the acquisition, aggregation, and provision of machine data via secure and standardized communication protocols such as OPC UA and MQTT.

INSYS icom contributes its proven expertise as a manufacturer of industrial routers for secure network connectivity, VPN-based remote access, and the management of industrial router fleets (icom Router Management).

Added value for machine builders, plant operators, and system integrators

The partnership provides users with consistent, clearly structured solutions for all areas of industrial connectivity: Secure connection of distributed systems, structured remote access, and standardized collection and integration of machine data for Industrial IoT and Industry 4.0 applications.

Joint focus on Industry 4.0 and Industrial IoT

“Partnering with INSYS icom is a logical step to provide our customers with even more comprehensive solutions for Industry 4.0, Industrial IoT, and remote services,” says Emrah Acar, Product Manager at Softing Industrial. “Together, we make industrial plants more transparent, efficient, and future proof.”

“With Softing Industrial, we have gained a partner with extensive experience in industrial data integration and automation,” says Anna Wels, Vice President Project Business at INSYS icom. “Together, we can offer customers end-to-end, secure, and scalable solutions for networking, remote maintenance, and Industrial IoT applications.”

ECS Summer School 2026: Empowering the Next Generation of Microelectronics Talents

ECS Summer School Applications Open for Undergraduate STEM Students in Europe

The European Chips Skills Academy (ECSA), a European Union (EU)-funded project coordinated by SEMI Europe, in collaboration with industry partners AENEAS, EPoSS, and INSIDE, announced on February 12 that applications are open for the ECS Summer School. Taking place from 23 – 28 August 2026 at the University Residential Centre, University of Bologna, Bertinoro, Italy, the programme invites applications from undergraduate STEM students across the EU and associated countries.

“Programmes such as the ECS Summer School are vital to motivating and developing the next generation of talent that will sustain Europe’s semiconductor workforce,” said Laith Altimime, President of SEMI Europe.

As Europe accelerates its transition to a digitally enabled future, demand for skilled professionals in microelectronics and semiconductor technologies continues to grow. The ECS Summer School offers a comprehensive, immersive learning experience designed to equip the next generation of engineers, researchers, and innovators with foundational and advanced insights into chip design, semiconductor fabrication, and embedded intelligent systems.

“The ECS Summer School provides students with a strong entry point to acquire practical skills and form valuable connections with industry and academia,” said Patrick Cogez, Technical Director at AENEAS and ECSA lead partner for the organisation of the Summer School.

The curriculum spans four core domains of microelectronics:

-

Semiconductor Technology,

-

Integrated Circuit Design,

-

Digital Systems and Embedded Intelligence,

-

Integration of Electronic Systems.

This year’s summer school will be co-organized by ABGi and IPCEI ME/CT. Lectures, demonstrations, and interactive activities will be delivered by experts from leading universities, research institutes, and industry partners, complemented by career testimonies from engineers working in the field.

Eligibility & Application Details

The Summer School is open to undergraduate students who will have completed at least two years of university study by the time of the event and who will still have at least one year remaining in their degree programme. Participants must be enrolled in a STEM (Science, Technology, Engineering, Mathematics) discipline at a university based in the EU or eligible associated country and possess a good command of English, as all activities will be conducted in English.

Registration details, application requirements, and the full programme overview are available on the official ECS Summer School 2026 page.

Automation Extended: Unlocking Industry’s Full Potential

A new wave of more efficient, adaptable and intelligent plant operations is emerging as conventional control systems evolve into modern, open and modular automation ecosystems. Stefan Basenach, Senior Vice President ABB Automation Technology, explains how ABB’s Automation Extended allows industrial organizations to fully embrace the opportunities of digitalization while futureproofing their operations.

Automation

For decades, industrial automation has been built on the simple overarching principle that reliability comes first. Distributed control systems (DCS) have delivered the deterministic, real-time control that industries depend on to keep energy flowing, chemicals processing, materials moving and goods produced safely and efficiently. Today though, that foundation is under unprecedented pressure. Market factors such as volatility, sustainability targets, cybersecurity threats, workforce change and the accelerating pace of digital innovation are all forcing industries to rethink how automation evolves without jeopardizing operations.

While the advent of Industry 4.0 saw the mass adoption of digitalization, it also highlighted the limited flexibility of existing systems to accommodate change, especially in terms of realizing the full benefits of the technology. Rapid developments in IIoT, cloud, edge and data analytics have blurred the lines between traditionally distinct IT and OT systems. In addition, operators have faced the translation of big data from field devices and connected systems into measurable gains in production efficiency, sustainability and resilience.

ABB’s new Automation Extended program is a direct response to these challenges. Instead of needing customers to replace what already works, Automation Extended provides a structured, future-ready way to modernize industrial automation while ensuring continuity, protecting prior investments and infrastructure and safeguarding mission-critical operations.

From traditional DCS to Automation Extended

Modernization in process automation has historically involved disruptive system migrations, major shutdowns or long upgrade cycles that force customers to choose between innovation and operational stability. While digital technologies, including advanced analytics, AI, edge intelligence and cloud connectivity have promised significant performance gains, integrating them into legacy control environments has often entailed increased complexity and risk.

Automation Extended represents a decisive shift. It is not a new DCS in the traditional sense, nor a bolt-on digital layer detached from control. Instead, it is providing new capabilities to ABB’s existing automation platforms through a modern, open and modular automation ecosystem, built explicitly to support continuous innovation without disturbing core control functions.

Crucially, Automation Extended builds on systems that customers already trust, specifically ABB Ability™ System 800xA®, ABB Ability™ Symphony® Plus and ABB Freelance. Tried, tested and proven in multiple applications across multiple industries, these platforms remain the backbone of plant operations, while new capabilities are introduced progressively and safely around them.

Separation of concerns

At the heart of Automation Extended is a modern modular architecture, characterized by the implementation of separation of concerns principles into two distinct but securely connected environments, each optimized for a different purpose and operating as a cohesive ecosystem.

The Control Environment is where deterministic, real-time process control takes place. It remains robust, lifecycle-resilient and cyber-secure, prioritizing availability, safety and reliability. This environment aligns closely with the traditional strengths of a DCS and continues to handle the immediate responses required for safe plant operation.

Sitting alongside it is the Digital Environment. This environment is essentially a flexible, modular space where innovation happens and where features and tools such as advanced analytics, AI-driven applications, condition monitoring, predictive maintenance, alarm management and decision-support tools can be deployed, updated or removed without affecting the core control functions.

This separation is what sets Automation Extended apart from previous approaches, by allowing each environment to evolve within its own lifecycle, at its own pace, while remaining securely interconnected. Lifecycle Services are integral to the automation ecosystem, enabling not only continuous updates but also optimizations without disrupting critical operations. This creates a trusted operational foundation for customers, allowing the automation ecosystem to remain innovative while safeguarding installed assets and ensuring seamless adaptation to future demands.

Innovation with continuity

For industrial operators, Automation Extended gives the ability to adopt new digital capabilities step by step that are aligned with their operational priorities, risk tolerance and business strategy. Rather than large, one-time transformations, modernization can now be achieved incrementally, with enhancements such as security patches, performance improvements and new applications added as and when necessary, without the cost, disruption and potential errors of carrying out a full upgrade or replacement.

With operators facing ever-pressing pressures on costs, this approach directly addresses the need to maximize the return on existing automation investments. With Automation Extended, the life and value of even decades-old plants can now be extended and augmented through access to modern technologies such as AI, edge intelligence and real-time analytics.

Automation Extended also helps customers manage the growing complexity of integrating different systems from different providers. Open standards such as OPC UA, together with cloud-native technologies and container-based architectures, enable interoperability across vendors, systems and domains. By removing issues such as compatibility and interoperability between different communications protocols, for example, they make it easier to integrate new tools, connect IT and OT environments, and scale solutions across sites or fleets.

Equally important is cyber security. The clear separation between control and digital domains, combined with lifecycle-driven services, helps organizations stay compliant with evolving regulations while reducing exposure to cyber risk.

Empowering a changing workforce

With humans still very much at the heart of industrial operations, there is a need to consider not only what new technology can do, but also how it interacts with those who need to use it.

As experienced personnel retire and are replaced by a new generation of digital-native engineers, there is a need to ensure that their operational knowledge is both preserved and made as easily accessible as possible.

Automation Extended provides intuitive, connected and collaborative tools that resonate with modern skill sets, while preserving the proven control logic and operational knowledge embedded in existing systems. Features such as advanced visualization, analytics and intelligent decision-support applications ensure that human expertise is augmented, helping operators and engineers make better decisions faster.

Crucially, Automation Extended provides the foundations for accommodating future changes. By anticipating future use cases, from predictive maintenance to expanding autonomous operations, it creates an environment where skills can evolve alongside technology, reducing the impact of knowledge gaps and supporting long-term operational resilience.

Enabling sustainability and performance at scale

Sustainability and regulatory pressures on energy, emissions and resources are increasingly reshaping the priorities of industrial companies. Meeting these pressures depends on better data, deeper insight and tighter integration between process and electrical systems.

By extending the reach of control systems into data-driven optimization, Automation Extended supports these goals. Enhancements such as continuous condition monitoring, AI-assisted performance analysis and real-time energy insights all enable more efficient operations without compromising safety or availability. Over time, these capabilities can help achieve the transition toward lower-carbon, more resource-efficient production models, while maintaining the reliability that essential infrastructure demands.

A unified lifecycle approach

Another defining element of Automation Extended is ABB’s comprehensive lifecycle services. Managing control and digital environments independently requires a coordinated approach to updates, maintenance and optimization. ABB’s lifecycle services ensure that systems remain secure, supported and future-ready throughout their operational life.

This proactive, service-driven model reduces total cost of ownership, improves system availability and assures customers that their automation environment can adapt to future demands whether driven by regulation, market shifts or technological change.

Unlocking industry’s full potential – today and tomorrow

With Automation Extended, ABB is not asking customers to abandon the systems that have served them well, but rather extending their value into the next era of industrial automation.

Automation Extended also reflects a broader shift in how industrial automation is evolving. By adopting emerging industry concepts such as NAMUR Open Architecture, software and hardware decoupling, and hyperautomation, ABB opens up new possibilities in industrial operations through greater openness, modularity, human-centric design and secure innovation.

Rather than locking customers into rigid upgrade cycles, ABB is positioning automation as a continuously evolving ecosystem that balances stability with agility, and reliability with innovation. For industries facing an uncertain future, this balance will be invaluable, providing the scalability and adaptability to meet future changes and challenges.

Stefan Basenach

He has worked at the Swiss group ABB for over 20 years and is currently Senior Vice President of Global Process Automation Technology. He is committed to implementing sustainable practices and played a key role in leading the ABB Process Automation Energy Division in Germany in supporting the energy industry in its transition towards a net zero economy.

He holds a Diplom Ingenieur degree in Technische Kybernetik (Technical Cybernetics) from the University of Stuttgart, specialising in control methodology for technical and non-technical systems with a focus on biochemical engineering.

I/O System for Extended Control Capabilities in Motion-Centric Machines

Direct integration of high-speed I/O via compact slices for more flexibility in machine development

Motors & Drives

The Trio Motion MS I/O System enables direct integration of I/O slices with a Motion-PLC controller. Highly efficient data transfer is achieved via Trio’s new MS-Bus interface, a local communication protocol for MS I/O slice connection that provides high data throughput for responsive machine control. The MS I/O system can be tailored to the connectivity requirements of the machine, allowing any combination of digital inputs and outputs, and analogue inputs and outputs.

I/O slices simply ‘click in’ via forward insertion, with fast and easy mounting to a DIN rail. Connection is achieved via spring clamp connectors for a tool-free, secure installation, combined with push button wire removal, making slice insertion and swapping fast and easy to achieve. Slices are just 12mm wide, minimising the footprint inside a cabinet or onboard a machine.

Coupler for port expansion

Up to 16 I/O slices can be directly integrated with a Motion-PLC controller, with extension achieved by adding one or more MS EC (EtherCAT) couplers. Each MS EC coupler can integrate a further 16 I/O slices, and in total, a Motion-PLC controller can be expanded to host 1024 digital ports and 128 analogue ports.As well as extending I/O connectivity, adding an MS EC coupler can also achieve a distributed I/O system, keeping I/O close to the sensors to reduce the cost and time of cabling. Instead, just a single cable is required to connect the MS EC coupler to a Motion-PLC controller. Multiple MS EC couplers can be connected to a single EtherCAT controller, including third-party controllers, to create complete control across a machine.

Connection to EtherCAT

Slices click in to the MS EC coupler, communicating with it via the MS-Bus interface, and the MS EC coupler acts as a high-speed bridge to the EtherCAT network. With update rates down to just 125µs, this achieves high performance for both motion control and machine control automation. With EtherCAT IN and OUT ports, the MS EC coupler can also be placed at any point across the EtherCAT network.

The Motion-PLC controller I/O slice interface and the MS EC I/O coupler are synchronized to Trio’s Motion-iX motion engine, enabling deterministic behaviour across all motion and machine connections. This ensures high-speed, reliable control to optimise control coordination. I/O integration and management is achieved through Trio’s easy to use MotionPerfect software for motion and machine set up.

The new I/O system is launched alongside Trio’s new Motion-PLC range that provides advanced motion control performance with the functionality and simplicity of a PLC. The new class of controller combines high-performance motion control over EtherCAT plus logic and I/O expansion, enabling faster, simpler machine development. The first controllers in the range are now available to order and scale machine and motion requirements up to eight axes.

Software Platform for Production Monitoring

Monitoring and reporting of production and energy data

Automation, Industry 4.0

CodeMaster is an Industry 4.0 application platform developed by MCS Group. It provides real-time traceability and sustainability reports, offering tangible advantages and gains. In line with the Industry 4.0 concept, it builds a bridge between the production site and management. The platform offers sector-specific solutions without discriminating between sectors, especially with regard to energy, maintenance and production outputs.

Production monitoring

Production operations can be monitored in real time, with operators able to follow all operations on kiosks at the plant. CodeMaster maximises the use of maintenance capabilities and increases machine utilisation. It reduces downtime of machines in operation.

Energy monitoring

CodeMaster enables real-time traceability to monitor energy consumption in operation. Energy can be monitored on a machine or production basis and calculate the total spent energy on a daily, weekly and monthly basis.

The smart control mode saves energy by momentarily stopping non-essential processes, while ensuring production traceability throughout the process. Monetary gains from daily and All-time energy savings are displayed on the screen.

Carbon emissions are calculated from the electricity and gas consumption during production and the Carbon Footprint is instantly displayed. This data can be integrated with ERP.

CodeMaster offers solutions with Operator Tracking control for accessing to machines and plants with maximum efficiency and process security. Operator can define the downtimes and send breakdown notification to maintenance by RFID cards.

Reporting

Production reports based on machines can be obtained from the CodeMaster platform. Energy and maintenance reports can also be added as optional extras. All information received in report form can be converted into file formats such as xls and pdf.

CodeMaster sets the standard for measuring production efficiency and provides OEE tracking to ensure consistent implementation of this standard. It reduces performance losses in the production process, minimises downtime and usability losses, and improves production efficiency by an average of 20% with effective quality monitoring.

DIN Rail Controller for Diverse Measurands

For precise control of temperature, pressure and more

Automation

The JUMO diraTRON DR100 DIN rail controller is an important tool for process control. The device can be adapted to different process requirements with configurable measurement inputs and control options as a two-point, three-point, modulating, or continuous controller. An analog output for controller, actual value, or setpoint output as well as 2 digital control signals for such uses as implementing simple logic functions or delayed switching on and off ensure a wide range of application possibilities. The integrated RS485 interface enables seamless communication with other systems and ensures easy integration into existing networks.

Rear panel bus for reduced cabling

All relevant information is displayed clearly and concisely on the text display. The rear panel bus enables quick and easy installation of up to 10 devices while at the same time reducing the amount of cabling required. The JUMO diraTRON DR100 is a versatile and user-friendly device that is attractive to a wide range of industries and applications. A key advantage is its easy integration into existing JUMO and third-party systems.

Ultra-Compact Industrial PCs for Demanding Automation Tasks

New processor generation increases computing power

Automation

Beckhoff’s C60xx scalable series of ultra-compact industrial PCs combines high computing power in an extremely compact format with a wide range of options for installation in the control cabinet. A new Intel Atom® processor generation now provides even more performance reserves in the devices, which cover the spectrum from low to high automation requirements.

Fanless design for complex automation tasks

With a new generation of processors, the C6015, C6017, and C6025 ultra-compact Industrial PCs can be used for even more demanding computing tasks than before, while retaining their compact form factor. The fanless devices are designed in particular for control, visualization, and communication – from complex automation and virtualization to use as an edge device or HMI platform. All of this benefits from the new Intel Atom® x7 CPU series, which offers up to eight processor cores and a 3.0 GHz clock frequency.

As the smallest device with dimensions of just 82 x 82 x 40 mm, the C6015 ultra-compact Industrial PC is ideal for highly compact applications, virtualization, and IoT. The same applies to the C6017 with an installation depth of 66 mm, which has an additional second board level for optional interfaces and integrated 1-second UPS. Measuring 82 x 127 x 47 mm, the C6025 can also be expanded to up to eight processor cores and used with high-performance SSDs and USB-C.

Reducing Maintenance by Removing Mechanical Motion

How an easy-to-use sensor module can bring flow intelligence to consumer and industrial equipment

Sensor Technology

For the coffee shop, the task is to draw the exact dose of water required to produce the full richness of a perfect cup of espresso. For the pub or bierkeller, it is serving exactly a half-liter of weissbier so that the customer gets no more and no less than they paid for. And for the industrial process control engineer, the requirement is to know exactly when a filter has cleaned its rated volume of water and is due for replacement.

In all these applications, accurate flow sensing can substantially increase the value of equipment or machinery. Traditional electromechanical technology for flow sensing has, however, been a pain point for system design engineers, causing performance and reliability headaches which have proved difficult to eradicate.

Pure electronic sensing using ultrasonic technology eliminates the moving parts from a flow sensor assembly, and provides an escape route from the problems with traditional flow sensors. When first introduced, ultrasonic sensor ICs posed a considerable integration challenge which generally restricted their use to the manufacturers of specialist measurement equipment.

But now successive generations of complete off-the-shelf ultrasonic flow sensing modules, which provide a simple measurement interface to any microcontroller, have made accurate, reliable ultrasonic flow sensing a valid option for non-specialist designers of any type of equipment which can benefit from flow rate measurement.

Stuck with traditional turbine-based flow sensors

Traditionally, flow sensing has been performed using a simple electromechanical assembly comprising a length of tubing containing turbines, which is positioned inline with the flow (see Figure 1). The speed at which the turbines rotate can be converted into a measurement of the flow rate. Over time, these measurements can be integrated to provide an absolute measurement of the volume of liquid that has passed through the sensor.

This method of sensing flow provides a simple measurement interface to an external logic device such as a microcontroller or programmable logic controller (PLC). But equipment manufacturers have to take account of serious drawbacks which can limit the sensor’s usefulness, or even make the sensor inoperable. The problems stem from inherent mechanical characteristics of the turbine or wheel in the assembly.

The first problem is that a turbine has friction which creates inertia: at low flow rates, the force of the flow will be insufficient to overcome the turbine’s inertia, and so the turbine will fail to rotate. As a result, a low flow rate will be registered as zero flow. Part of the value of many applications for flow sensing is the ability to measure leakage – in other words, a fault condition in which the flow is continuous, but at a much lower rate than in normal operation. In this case, an electromechanical flow sensor will be able to measure normal flow, but will likely fail to alert the operator to leakage.

The second problem with turbines is catastrophic failure: the turbine is a moving part, and so can become corroded or broken. Reliability is a key issue for users of flow sensors: mechanical flow sensors suffer from wear and tear which limit their operating lifespan.

Ultrasonic flow sensing technology eliminates moving parts

If the problem is the presence of a mechanical component in the flow to be measured, then the solution is to measure flow contactlessly. This can be accomplished by ultrasonic sensing technology.

Ultrasonic flow sensors measure fluid flow rate by transmitting sound waves through the flowing medium via paired transducers positioned diagonally across the pipe. One transducer sends ultrasonic pulses downstream while the other sends them upstream. The flowing fluid affects propagation speed: downstream pulses travel faster (aided by the flow) while upstream pulses travel more slowly (impeded by the flow). Flow velocity is directly proportional to the difference in transit times between these paths.

This non-intrusive measurement technique works with clean liquids and gases, has no effect on the flow medium itself, and scales across various pipe diameters. Crucially, it also eliminates the drawbacks of turbine-based mechanical flow sensors. The absence of moving parts inside the flow medium means that the sensor offers a practically unlimited operating lifespan, and can also measure extremely slow flow speeds.

Implementation of this method of flow sensing calls for extremely accurate measurement of the small-time differences between downstream and upstream sound transmission – a phenomenon measured in picoseconds.

In fact, the entire time signal-processing function may be implemented by an ultrasonic flow converter IC from ScioSense. This highly integrated device, shown as the ‘UFC’ block in Figure 2, triggers the twin transducers, measures the time difference between the return signals, and converts the measurements to a flow rate and accumulated volume data for any given pipe diameter.

Key design considerations in ultrasonic flow metering

To integrate an ultrasonic flow converter (UFC) into a flow sensor system, the designer has to take account of various considerations which affect the operation of the technology. These include:

- The transducer mounting geometry.

- The acoustic properties of the pipe material - metals, plastics, and composite pipes each have different acoustic impedances and attenuation characteristics. Wall thickness, surface finish, and coatings can reflect or absorb acoustic energy. The acoustic path must also account for refraction at material boundaries.

- Temperature variation - sound velocity in fluids varies significantly with temperature. For instance, the speed of sound in water varies by approximately 0.6%/°C.

Off-the-shelf modules provide ready-made solution

Specialists in flow measurement system integration, such as water utility meter manufacturers, maintain internal design expertise to enable the integration of a UFC into a custom flow sensor assembly, taking account of the factors listed above.

But the wider application of flow sensing has value in a broad range of other types of equipment. Examples include:

- Coffee brewing machines,

- Beverage dispensers,

- Water purifiers,

- Water heaters, boilers and heat pumps,

- Irrigation systems,

- Cooling machines,

- Industrial process control systems and filters,

- Livestock feeding equipment.

In these applications, flow sensing is a peripheral rather than a primary function, and so here OEMs typically prefer a ready-made, off-the-shelf ultrasonic flow sensing solution which dramatically reduces design time and effort and accelerates time to market.

Complete ultrasonic flow sensor modules meet this market need. ScioSense is a pioneer in this market, offering first the UFM-01 and, in 2025, launched an improved version, the UFM-02. The advantage of a modular solution is that it is extremely easy to integrate into end equipment designs. In the case of the UFM-02, for instance, the module is available in two thread sizes: 0.5” and 1”, each provided in either a BSPP (British Standard Pipe Parallel) or NPS (American National Pipe Straight) format. Two more thread sizes, 3/8” and1.5”, will be available soon. The smallest thread size manages a maximum flow rate of 20l per minute, and the largest, up to 450l per minute.

he module is highly sensitive to slow liquid flows, allowing the sensor to accurately detect leakage. In its smallest, 3/8” thread size, the UFM-02 can measure flows as slow as 0.03l per minute.

The UFM-02 is also easy to interface to any microcontroller or PLC. The module is available with a choice of two cable connections. A four-wire pulse interface cable provides a simple output signal with up to 450 pulses per liter and a 10-wire SPI cable which provides digital data including total volume of liquid flow in cubic meters, filtered flow rate in liters/hour, and a measurement of the liquid’s temperature.

An important development in the second-generation UFM-02 module is its power consumption, which is substantially lower than in the UFM-01. Average operating current has been reduced to 50µA, low enough to enable applications to run for years on a standard primary battery.

The introduction of this latest module means that a drop-in solution for ultrasonic flow sensing can now be implemented in applications which cannot easily be connected to a mains or other external power supply and so rely on battery power.

Module manufacturer with a long heritage in ultrasonic flow sensing

Ultrasonic flow sensing provides a reliable, accurate and sensitive alternative to traditional mechanical flow sensing. By using a modular off-the-shelf sensing assembly, OEMs can take advantage of these qualities of ultrasonic technology in a solution which is easy to integrate into an electronics system.

Designers who evaluate the latest UFM-02 module can also take confidence from the long heritage of ScioSense, a company which introduced its first ultrasonic flow converter IC more than 25 years ago, and which can offer customers deep expertise in every aspect of the implementation of ultrasonic technology for flow measurement.

Empowering Humanoid Robots

As the robotics sector steadily moves from science fiction to factory floor, a new generation of humanoid robots is emerging to reshape industry, healthcare, and daily life.

Motors & Drives

This class of machines are designed to do more than automate. They're built to move like us. They're built to work alongside us. And at times, they're even built to stand in for us.

Yet replicating human motion is not just a question of software and AI. It starts at the core components that enable this movement, with actuators and motors that combine compact size, lightweight design, and remarkable performance.

That’s where Portescap comes in. As part of the Regal Rexnord family of brands, Portescap brings decades of experience in miniature motion systems and a proven track record in high-performance medical and industrial applications. Today, it is supporting a new wave of robotics OEMs as they transition from prototype to production.

The rise of humanoid robotics

The idea of a humanoid machine has fascinated engineers, scientists, and storytellers for over a century, appearing in literature and early cinematic visions of the future long before the technology existed to make them real. Early attempts at humanoid robots in the mid-to-late 20th century were largely experimental, often limited to slow, rigid movements and basic programmed routines.

Since the turn of the millennium, however, a combination of breakthroughs in AI, computing, motion control, and materials science has brought the concept within reach. Today, humanoid robots are being developed with increasingly sophisticated capabilities: they can walk, balance, manipulate objects, and respond to voice commands or sensory feedback.

The purpose of this form factor is not simply to mimic the human body for its own sake. It allows these robots to interact with human environments, designed around our size, tools, and workflows, without needing extensive changes to infrastructure. That makes them well-suited to working alongside people, whether on production lines, in warehouses, in healthcare settings, or in the field.

Preparing for harsh environments

Many of today’s robotics applications are destined for highly controlled environments like warehouses or hospitals. However, as the technology matures and its capabilities grow, there's a very good chance that tomorrow’s systems may need to walk the ocean floor, enter radioactive zones, or carry out maintenance in the vacuum of space.

In many of these environments, human workers would face unacceptable risks from heat, pressure, radiation, or isolation. Humanoid robots and exoskeletons offer a way to extend human capability into these hazardous zones, performing tasks remotely, reliably, and – vitally – without exposing human operators to danger.

These scenarios demand more than smart AI; they require mechanical systems engineered to endure the extremes. Portescap is already well-prepared for these scenarios, however, as it has extensive experience in building motors for extreme conditions, such as high heat, chemical exposure, vibration, and more.

While many robotic applications are still pre-commercial, Portescap is already developing solutions that can handle these tough operating conditions. With sealing, insulation, and specialised materials, the company is ready to support OEMs as their applications move off the lab bench and into the field.

Making hands work

One of the key requirements of any humanoid robot is the ability to interact with its environment in the same way a human would. As such, it's vital that they have functional hands.

Achieving this, however, is not necessarily a simple task.

Although we often take it for granted, the human hand is a marvel of engineering, one that is capable of delicate manipulation, strong grip, and complex motion, all in a compact, adaptable form. This means that any robotic replica must be small enough to fit inside human-like form factors, strong enough to grip and lift weight, and smart enough to know just how much of that strength to use.

To meet this challenge, Portescap offers a wide portfolio of motor topologies and technologies. Cylindrical motors, shaped like slim batteries, can be embedded in fingers or palm area. Flat motors, meaning with short axial distance, offer high torque in compact packages for wrists or arm integration. Crucially, the company also provides brushed DC, hybrid stepper, and brushless DC options (including both slotted and slotless designs), helping developers strike the right balance of speed, torque, smoothness, and efficiency for each axis of motion.

But components alone don’t make a system. What sets Portescap apart is its "engineer-to-engineer" approach. The company works directly with roboticists, guiding design teams through motor selection, integration with gearheads and encoders, and performance optimisation to achieve specific motion goals. Whether an OEM needs fast, high-volume gripping or smooth, multi-articulated gestures, Portescap can configure a solution that fits the form and delivers the function.

Bringing bionics to life

Humanoid robots are not the only application for this kind of solution, however. Perhaps the most immediate and transformative impact of robotic hand development instead lies in prosthetics.

Portescap’s technology is already powering a new generation of bionic limbs that combine functional grip with intuitive control. These solutions go beyond raw motor specs, drawing on a deep understanding of cost, weight, and patient ergonomics.

Prosthetic developers often target around 80% of human hand dexterity, with 10-20 basic motion patterns. These designs must be lightweight, durable, and efficient, while remaining affordable for cost-sensitive markets. Portescap’s experience in both premium and value-engineered designs makes it well suited to this space.

From proof-of-concept to scaled production

Across the industry, OEMs are racing to prove the value of next-generation robotics. Demonstrator units and pilot projects are being used to unlock funding, attract strategic partners, and secure long-term market positions. That means motion system partners must be able to deliver quickly, reliably, and flexibly.

Portescap supports this full journey. The company can provide small quantities for R&D testing and validation, then take advantage of Regal Rexnord's global reach and engineering expertise to scale seamlessly to support commercial launches, with lead times and production infrastructure already proven in demanding sectors like medical devices and aerospace. This makes it not just a component provider, but a long-term platform partner.

This scalability also enables cost-effective iteration. Customers can test several configurations or gear ratios in parallel, then down-select based on actual test data. Portescap’s global support network helps manage this process efficiently, reducing development risk and time to market.

Partner for the Next Generation

As robotics moves toward real-world deployment, success will come down to more than innovation. It will require motion solutions that are engineered precisely, delivered reliably, and scaled effectively.

From form-fit options and technical expertise to production agility and application support, Portescap offers everything OEMs need to bring humanoids and exoskeletons to life. In a field where form follows function, the company is ready to power what’s next. And as part of Regal Rexnord, it does so with the strength and support of a global organisation, combining local expertise with worldwide reach to help OEMs turn ideas into fully realised, market-ready solutions.

Planetary Gearbox-Series with Hollow Input and Output Shafts

Available in three frame sizes with a wide gear ratio range

Motors & Drives

Apex Dynamics has launched its accurate, compact and powerful range of PFII planetary gearboxes. Designed for use in shaft-driven actuators, linear units and machine axes, the PFII Series delivers high torque, low noise and precision. With an extremely compact and efficient design, PFII gearboxes feature an innovative coaxial configuration using a hollow input and output shaft. This means the output shaft is in line with the motor shaft, combining excellent performance with smart design.

PFII gearboxes feature hardened planetary gears, combining high torque and precise operation with low noise and high speed. In addition, the adapter housings are made from lightweight aluminium to reduce weight without compromising performance or reliability, and internal gearing is made from alloy steel to support both high torque and rigidity.

Advanced clamping ring

The PFII comes in three frame sizes, with a wide range of gear ratios from 3:1 to 1000:1, offering high flexibility. It provides high performance with a rated torque up to 232 Nm and high accuracy, with backlash down to six arc minutes. One of the key features of the PFII range is the way in which the output shaft is clamped. A radial clamping ring is used for both input and output shafts, with the clamping ring on the output side equipped with two radial bolts to handle higher torque. This offers significant benefits over traditional systems, providing easy assembly and maintenance, and compact design as well as higher tolerance, robustness and greater suitability for dynamic applications.

The PFII enables shaft-to-shaft power transmission connection between two rotating shafts and versatile mounting specific to the motor. Customized adapters are available for shaft actuators, while Apex Dynamics can also supply couplings where they are required.

Tailor-Made Electromechanical Drives

Offering a wide range of output forces with short lead times for industrial applications

Motors & Drives

With the new Industrial POWERISE IPR40, Stabilus introduces custom-made electromechanical drives for industrial applications. The "Customized to Order" option allows clients to configure actuators precisely to their specific design, starting from ordering amounts of one actuator to any desired number.

Customer specific orders

Designers who do not find what they need in Stabilus' standard actuator range can now request a customized solution with short manufacturing and delivery times. Depending on the application, engineers coming from Stabilus or from its expert brands ACE Stoßdämpfer GmbH or HAHN Gasfedern GmbH will support customers from the design phase to commissioning.

The slim, compact IPR40 electromechanical spindle drives can be precisely customized to customer specifications in terms of connections, output forces, stroke lengths and speeds. They require little installation space and are available with either 12 V or 24 V power supply and in a waterproof IP67 version. Furthermore, IPR40 can be ideally combined with industrial gas springs from the Stabilus Group when designs require movement and control of larger masses. The services accompanying these customized drive innovations include design, configuration, and commissioning, on-site if desired, including all settings and parameterization of the electronic control units (ECUs).

Following this most recent market launch of IPR40 type actuators, Stabilus will extend the Customized to Order option to its entire family of electromechanical drives, encompassing the IPR35, IPR35 SMART, and IPR40 SMART models.

Compressor Motors with 5.5 to 250 kW

Designed for heavy-duty compressor applications

Motors & Drives

Electric motor manufacturer GAMAK delivers high-performance solutions designed to meet the most demanding industrial applications. The GAMAK Compressor Motors set a trusted benchmark for performance-critical compressor systems. The series of high-performance induction motors are specifically engineered for demanding compressor applications. The series covers power ratings from 5.5 to 250 kW and is available in IE3 and IE4 efficiency classes for optimized energy use.

VFD-ready construction with reinforced insulation

Designed for variable and continuous load operation, the motors feature a service factor of 1.15 or higher and enhanced starting torque characteristics, enabling reliable startup and safe handling of temporary overloads caused by high starting torque, pressure fluctuations, and abnormal operating conditions. The service factor acts as a built-in safety margin, extending maintenance intervals, reducing failure risk, and ensuring stable operational continuity. VFD-ready construction with reinforced insulation according to IEC 60034-18-41 ensures reliable operation under high dv/dt and PWM stress. High-power versions are equipped with insulated bearings to prevent bearing currents. H-class insulation with PTC thermal protection, IP55 enclosure, and TEFC cooling provide durability, low maintenance, and long service life for compressors, refrigeration systems, pumps, and fans.

Firmware Upgrade for Advanced Linear Motor Safety

Servo drives and motion system with EnDat 2.2 protocol integration

Motors & Drives

Kollmorgen released the next update for the SafeMotion™ Monitor (SMM) firmware: SMM 3.0. This upgrade expands functional safety support for linear motors and linear axes, helping machine builders implement functional safety in applications ranging from semiconductor manufacturing to battery production and industrial automation that require safety.

Integrated into AKD2G servo drives and the Kollmorgen 2G Motion System, SMM 3.0 continues to work with all motors that feature any HIPERFACE DSL® rotary-safe feedback system. It also allows the AKD2G drive to now support EnDat 2.2 safe feedback systems to better serve the growing demand for high-performance safety solutions in precision motion control.

Performance and safety up to SIL 3 level

The EnDat 2.2 safe protocol, now supported by ADK2G drives and 2G Motion System, delivers dual independent positioning for robust error detection, high-speed serial data transmission for fast cycle times, integrated diagnostics with comprehensive monitoring, and flexible encoder support for incremental and absolute feedback drives.

Kollmorgen’s AKM2G and AKMA servo motors also include an EnDat 2.2 safe feedback option, offering even higher performance and accuracy than HIPERFACE DSL for axes where functional safety is required. When combined, machine builders get a complete, integrated motion solution for safety-related applications.

SMM 3.0 enables complete motion systems to achieve Safety Integrity Level 3 (SIL 3) certification. While the AKD2G drive has maintained SIL 3 certification since launch, the addition of EnDat 2.2 safe feedback support now provides a complete, matched solution capable of meeting this rigorous standard. This is especially important where operators face frequent high-risk scenarios, such as stage lifting systems and heavy material handling equipment. Furthermore, the SIL 3 capability helps future-proof systems so they can scale as safety requirements evolve.

Sine-Wave Drive Controllers for Three-Phase BLDC Motors

For reduced noise and increased control efficiency regardless of motor type

Electronics & Electricity, Motors & Drives

Toshiba Electronics Europe has launched two sine-wave pulse width modulated (PWM) drive controllers – TC78B043FNG and TC78B043FTG – for three-phase brushless DC (BLDC) motors, which can support both surface permanent magnet (SPM) and interior permanent magnet (IPM) motor types with low noise and high efficiency. In recent years, there has been an increasing trend to use IPM types in preference to SPM types for three-phase BLDC motors to achieve low cost, high output, and high torque. Typical applications include home appliances such as air conditioners and air purifiers, as well as a wide range of industrial equipment. However, IPM motors are prone to generating vibration and noise, so motor controllers that reduce noise and enhance control efficiency are in high demand.

The newly released devices incorporate a high-resolution sine-wave drive and support sine-wave start-up, which helps to reduce vibration and noise. In addition, according to the characteristics and usage of the motor, various speed settings can be programmed into the built-in non-volatile memory (NVM) via the Serial Peripheral Interface (SPI). This capability allows high-efficiency motor control by adjusting parameters such as lead angle control.

Pre-programmed speed profiles

A key difference between the two devices is that the NVM in the TC78B043FNG comes pre-programmed with the initial speed profile settings for common motors. This negates the need to manually program or configure it further before using it, accelerating development time. Furthermore, the TC78B043FNG has four terminals: FGC terminal, LATYPE terminal, LAOFS terminal, and LA terminal. The voltage settings of these terminals also allow more detailed readjustment of motor control parameters on the NVM without the SPI interface, such as motor lead angle control.

Operating from a supply ranging from 6V to 23V, these motor controllers perform over a wide temperature range from -40°C to +115°C. They also integrate thermal shutdown, under voltage lockout, current limiter, over current detection, and lock protection. Both devices include built-in 5V regulators, providing a stable supply for external components such as Hall sensors or logic circuits, reducing the need for an additional voltage regulator in the system design. The TC78B043FNG is housed in the widely used HTSSOP28 (6.3mm x 9.9mm) package, making it easy to mount on the board due to its lead package. On the other hand, the TC78B043FTG is housed in a compact, leadless WQFN20 (3.0 x 3.0mm) package, enabling miniaturisation of the circuit board and mounting in limited spaces.

Why Motor Efficiency Is the New Baseline, Not the Finish Line

ABB is changing the energy efficiency game with its new IE6 synchronous reluctance (SynRM) motor range, bringing hyper‑efficient, magnet‑free performance to key industrial applications.

Motors & Drives

If you want to understand the future of industrial decarbonization, look at the motors behind every pump, fan, and conveyor. According to the International Energy Agency’s (IEA) Energy Efficiency 2025 report, motor systems today account for around 60% of global industrial electricity demand and roughly one quarter of all electricity use worldwide.

Behind the numbers is a simple story: industry depends on motors, and the planet now depends on how efficiently they run. Yet more than half of all industrial motors in operation are estimated to be over ten years old, and almost a quarter are more than twenty years old. These ageing assets often run continuously, kept in service on a “if isn’t broken, don’t fix it” basis – even though their inefficiency quietly drains energy and productivity with every hour they run.

In a world racing to cut emissions and boost productivity, this is one of the biggest opportunities hiding in plain sight. Upgrading the motors that already power our world is a fast, tangible way for manufacturers to use less energy today, tomorrow, and for years to come.

The potential impact is enormous. If the more than 300 million industrial motor‑driven systems operating today were upgraded to high‑efficiency versions, global electricity use could be cut by up to 10%. The tools to unlock those savings already exist, and synchronous reluctance (SynRM) motors are one of the clearest examples of how industry can act now, without hesitation.

Cutting inefficiency and risk with SynRM technology

ABB first introduced SynRM motors in 2011 as a way to combine high efficiency with simplicity and robustness. Instead of relying on magnets or complex rotor constructions, SynRM strips the design back to essentials. It delivers the performance of an advanced motor without rare earth materials and with far less wasted energy inside the motor itself.

In a SynRM motor, winding temperatures can be up to 30°C lower and bearing temperatures up to 15°C lower than in a comparable induction motor. Less heat means less risk of failure, which means less unplanned downtime – so operators avoid the disruption and costs that inevitably come when critical equipment fails. And because there are no magnets, SynRM means operators can avoid the price volatility and supply‑chain risk of rare earth metals. That makes it a more predictable long‑term choice, helping manufacturers stabilize costs and reduce their dependence on global supply chains.

The IE6 SynRM range takes this technology to the next logical step. It brings performance into the mainstream by offering IE6 Hyper-Efficiency as a standard option for key applications such as pumps, fans and compressors. Motors of this class are no longer reserved for special projects or bespoke engineering; they follow traditional power and frame‑size combinations, so most of the time they can simply replace older motors without requiring a redesign of the surrounding equipment.

The savings hiding in every kilowatt

Over a typical 20‑year lifetime, around 97% of a motor’s total cost of ownership is the electricity it uses. The purchase cost accounts for only about 2%, and maintenance about 1%. When energy dominates the cost of ownership to this extent, maximizing efficiency is the only rational strategy.

The step from high efficiency to hyper‑efficiency may sound incremental, but in continuous‑duty applications, the effect quickly stacks up. In a 110 kW motor application running 8,760 hours a year at around 75% load, upgrading an existing IE4 SynRM motor and drive package to ABB’s IE6 SynRM package delivers a major long-term gain. Over a typical 20-year service life, annual savings add up to roughly €51,200 and 92,200 kg of CO₂ – the equivalent of taking 21.5 gasoline‑powered cars off the road for a year. And for operators already thinking of upgrading from IE4 to IE5, going one step further to IE6 can unlock up to 76% greater energy and emissions savings than an IE5 solution. Plus, the additional investment required for an IE6 package over an IE4 one can be recovered in around eight months.

IE6 efficiency is proof that savings are within reach – in lower energy use, faster ROI and deeper emissions cuts – especially when these gains are multiplied across dozens or hundreds of motors. And by cutting running costs and reducing exposure to energy price volatility, SynRM technology helps manufacturers sharpen their competitiveness in markets where both margins and carbon performance are under pressure.

Efficiency as a management discipline

The IEA’s analysis of more than 300 energy management case studies around the world found that sites with structured energy management systems achieved average energy savings of 11% in the first years alone, with many reaching 30% or more over time. These improvements are rarely thanks to a single technology. Instead, they come from treating energy efficiency as a management discipline – starting with smarter equipment choices.

Hyper‑efficient motors like ABB’s IE6 SynRM motors do not require radical process changes or unproven technologies. They can be integrated into existing systems and start reducing usage immediately. They make it easier for energy managers to hit decarbonization targets, stay ahead of tightening regulations, and show concrete progress to stakeholders.

The sustainability benefits start even before the motor is switched on. IE6 SynRM motors are part of ABB’s EcoSolutions portfolio, which includes third‑party‑verified Environmental Product Declarations to support transparent lifecycle assessments and ESG reporting. ABB is also using low‑carbon and recycled copper in motor production, reducing embedded emissions by up to 200 kg of CO₂ per 75 kW motor.

As a result, true high efficiency is no longer confined to a few flagship projects, but can now be applied as standard across entire motor fleets.

Making hyper‑efficiency the new normal

Industrial companies today must do more with every unit of energy they use, and simply keeping equipment running is no longer enough. It has to run leaner and cleaner than ever before.

With IE6 SynRM motors, upgrading outdated fleets becomes one of the simplest ways to navigate rising energy costs and carbon constraints – and to turn energy efficiency into a guiding principle that defines the next generation of industry.

At ABB, we call this “Engineered to Outrun”: the belief that there is always another step to take in efficiency and sustainability. By making hyper‑efficiency available as a standard solution across a range of industrial applications, ABB is allowing manufacturers to treat motor upgrades as a central pillar of their decarbonization strategies. And in doing so, industry can align growth with sustainability, instead of trading one for the other.

To find out more, please visit: IE5 and IE6 Synchronous reluctance safe area motors

M8 and M12 Device Connectors

Different pin and coding options suitable for automated production processes

Automation, Electronics & Electricity

Phoenix Contact is extending its range of device connectors for the transmission of data, signals, and power. The new M8 and M12 versions are suitable for direct integration into SMT soldering processes. The M12 SMD connectors are available with different pin assignments and codings. This offers users numerous application options. The connectors have been developed for automated assembly and therefore enable efficient production processes. In combination with the push-pull housing screw connections, the connectors offer futureproof connection technology.

Design enables uniform installation height

The new design brings further advantages: The optimized shielding concept reduces mounting and spring forces, facilitates mounting and ensures reliable shielding transmission. The shortened alignment pins make it possible to assemble the PCB on both sides. The uniform installation geometry of the compact connectors simplifies the device design and enables a uniform installation height across all versions. The connectors meet the requirements of RoHS II without exemption 6c and are therefore fit for the future.

3-Phase Input 4500 W AC-DC Power Supplies

Capable of providing single or dual outputs in different proportions

Electronics & Electricity

TDK-Lambda introduces the TPS4500 single- or dual-output industrial power supplies with a 4500 W rating. The modules can be configured to share the loads in any proportion, up to the rated output specifications, and are designed to operate in series or in parallel to increase the output voltage or power. Capable of operating from a high voltage three-phase input in a 360 – 528 Vac Delta or Wye configuration, the series can be used in multiple applications, including test and measurement equipment, semiconductor fabrication, additive manufacturing, printers, lasers, and RF power amplifiers. The high voltage, three-phase input avoids the requirement for costly step-down transformers and assists phase load current balancing.

The TPS4500 series is fully featured with isolated AC Fail, DC Good and dropped phase signals, remote on/off, remote sense, and a 12 V, 0.3 A standby supply. The PMBus™ communications interface enables comprehensive remote monitoring and control. It provides real-time visibility of key parameters such as output voltage, output current, internal temperature, status signals, and fan speed. Additionally, PMBus™ allows programming of critical settings, including output voltage, overcurrent limit, and remote on/off functionality. Nominal outputs of 92 V, 49 A and 184 V, 24.5 A are fully adjustable via PMBus™: 92 V can be set from 10 – 96.5 V, and 184 V from 20 – 193 V.

Robust design for operation in a wide temperature range