Quick access

Industry News2 Industry News3 White papers4 Event: Industrial Cyber Sec Forum 20235 Robotics + Adhesives: A Powerful Combination6 Digital Twin Technology7 Smart Building & Factory Automation8 ODVA at SPS 20229 Siemens & Inovance at SPS 202210 Optical Mounts, Flow measurement & SPoE Solutions11 Box PC & Robotic System12 DC/DC Converters, Space-ready Optics & UHF Transmitter & Receiver13 TIMGlobal Media on Business TV show14 Index15 Contacts16Companies in this issue

Circuit Design Inc.13 Traco Electronic AG13 VPInstruments44 Analog Devices GmbH11 ArtiMinds Robotics GmbH8 Circuit Design Inc.13 Distec GmbH12 Microchip Technology2 ODVA Open DeviceNet Vendors Association9 Optical Surfaces Ltd11 Resolve Optics Ltd13 Siemens AG10 Titan Enterprises Ltd11 Traco Electronic AG13 VPInstruments4

Microchip Launches Radiation-Tolerant Power Management Device Targeting Low-Earth Orbit Space Applications

Space system developers can quickly develop prototypes and final designs for their power management system with a radiation-tolerant device based on a familiar plastic COTS device

Electronics & Electricity

The commercialization of the Low-Earth Orbit (LEO) region is transforming space exploration and satellite communication at roughly 1,200 miles above Earth. For satellites to successfully operate and reach their destination it is essential to select components that can withstand the harsh space environment. Building on its existing radiation-tolerant portfolio, Microchip Technology Inc. announces the introduction of its first commercial-off-the-shelf (COTS) rad-tolerant power device with the MIC69303RT 3A Low-Dropout (LDO) Voltage Regulator. The new high-current, low-voltage MIC69303RT is a power management solution targeting LEO and other space applications. The device is available for prototype sampling in both plastic and hermetic ceramic to support the requirements of the mission.

The MIC69303RT is based on proven COTS devices making it easier to conduct preliminary evaluation and early development. Operating from a single low voltage supply of 1.65 to 5.5 volts, the device can supply output voltages as low as 0.5V at high currents, offering high precision and ultra-low dropout voltages of 500 mV under extreme conditions. The MIC69303RT is a companion power source solution for Microchip’s radiation-tolerant space-qualified microcontrollers such as the SAM71Q21RT and PolarFire® FPGAs including the RTPF500TLS.

“MIC69303RT is Microchip’s first rad-tolerant power management device with a hermetic ceramic package, latch up immunity and 50 Krad total dose robustness,” said Bob Vampola, vice president of Microchip’s aerospace and defense business unit. “Microchip has over 60 years of space flight heritage in a comprehensive portfolio that allows customers to choose products designed to work together and accelerate their design processes.”

“This COTS rad-tolerant power management solution enables new design possibilities in space applications,” said Keith Pazul, director of marketing for Microchip’s analog power and interface business unit. “Customers can design their space system with confidence by selecting the COTS MIC69303RT space-qualified part to power Microchip space-qualified MCUs and FPGAs.”

Designed for harsh aerospace applications, the MIC69303RT is operational in temperature ranges from -55°C to +125°C. It is offered in 8-pin and 10-pin package configurations with radiation tolerance up to 50 Krad. The low noise of the output is critical to sensitive RF circuits, post regulation of switching power supplies and industrial power applications.

The MIC69303RT device is the newest space-qualified product by Microchip and is manufactured in compliance with the following MIL Class Q or Class V requirements: screening testing, qualification testing and TCI/QCI specifications. The plastic MIC69303RT is compliant with high reliability plastic quality flow derived from AEC-Q100 automotive requirements with specific additional tests necessary for space applications.

Development Tools

The MIC69303RT Plastic Evaluation Board is designed to evaluate the performance of the plastic engineering IC version for the MIC69303RT. The 4-layer PCB allows the user to easily change and measure the electric parameters of the device at different input and output conditions.

5G Smartphone for Hazardous Areas

World's first in its kind for ATEX and IECEx zone 1/21

Automation, Industry 4.0

i.safe MOBILE, innovation and global market player for explosion-proof mobile devices and solutions announces the immediate availability of the world's first 5G smartphone for ATEX and IECEx zone 1/21. The intrinsically safe mobile device, which was also developed for use in 5G campus networks, offers companies great flexibility potential thanks to its wide range of possible applications, especially in the automation sector.

The extensive deployment scenarios range from predictive maintenance, AR applications, control and cooperation of production robots and production lines, management of Automated Guided Vehicles, remote monitoring and support to PTT video calls in the system area to prevent plant failures. The high-performance Qualcomm® QCM6490 chipset, a large 6-inch display, 48 MP main camera, and standards such as Wi-Fi 6, Bluetooth 5.2 and NFC complete the Android 12 smartphone's extensive feature package.

5G as a convergent key technology to the enterprise of the future

Thanks to the ongoing development towards 5G technology and the use of compatible mobile devices such as the IS540.1, companies can digitalise their production facilities and processes even further and fully utilise applications such as remote maintenance, IIOT and augmented reality now also in the sensitive Ex zones.

Fields of application for the new IS540.1 industrial smartphone from i.safe MOBILE are scenarios in hazardous areas involving autonomous driving on campus grounds, platooning (automated column transports e.g. on large company premises with 5G campus network), control and monitoring of mobile robots, near real-time monitoring in process automation, workflow in the control loop and in plant management, logistics management, asset tracking and site access tracking,

Performance, safety, clarity and usability

The Qualcomm® QCM6490 chipset offers the smartphone powerful AI and computing functions, while the 48 MP main camera offers highest image quality. Dual Band Wi-Fi 6 (with 2.4 and 5 GHz support) connectivity enables additional efficiency gains, faster data transmission at higher data rates in industrial communications.

Peripheral devices such as a wired RSM (IS-HS2.1) for secure PTT/PoC communication, a high-performance barcode scanner (IS-TH2xx.1) or a thermal camera (IS-TC1A.1) can be connected via the 16-pin ISM interface.

ION Science Holdings Acquires Analox to Further Accelerate Growth

ION Science, developer and manufacturer of PID gas sensors and instruments, has announced the acquisition of Analox Group, a gas sensing and analysis manufacturer based in Stokesley, North Yorkshire.

“This is a major step on our strategic growth journey,” explains ION Science Group Managing Director, Duncan Johns. “With strong brands in global markets, ION and Analox will continue to operate separately. However, both companies invest heavily in research and development, so by working together, we are really excited by the opportunities this acquisition presents for accelerating future growth.

“Importantly, both companies share a common focus on customers’ needs, and especially product quality and reliability. We also both supply OEM sensors and engineered solutions, so customers can expect a broader range of solutions in the future. From an ION Science perspective, this move will expand the range of measurement technologies that we will be able to offer, which means that in addition to VOCs, we will also offer detection and measurement solutions for a wide range of other gases.”

Analox Managing Director, Emma Harbottle says: “Over the last 40 years we have designed and developed innovative gas sensing solutions that truly solve our customers' challenges. We are extremely proud of the reputation we have built, especially in the defence, beverage & hospitality and laboratory sectors. By working closely with ION we can continue to build on the success of both companies and I am excited to see what the future holds.”

Continental Strengthens Drive Belt Portfolio Of Industrial Division Through Uniform Brand Identity

More efficient handling thanks to globally harmonized portfolio and naming structure for industrial drive belts

Standard, Advanced, Supreme Performance: This is how the performance level of Continental’s drive belts is set up to be identified in its industrial segment in the future – uniformly, worldwide. With its new and globally aligned name and brand structure, the technology company aims to bundle its forces for a clear, comprehensive and efficient presence. “We are harmonizing our portfolio worldwide and improving transparency for our customers, who can now read the performance level and properties of a belt directly on the product,” says Rodrigo Maia, who heads up Continental’s industrial drive belt business. “With our unified approach, we will continue to strengthen the Continental brand and our belts will appear in the premium look that matches their product quality. This opens the door for further improvements and new products.”

In concrete terms, this means that Continental will not only make its belt portfolio more transparent, but also improve the performance and properties of some of its belt series. Moreover, completely new product lines are being launched on the market to expand the existing range. “Our customers and partners, and of course ourselves, will benefit from our globally harmonized, transparent and broad portfolio. If, for example, a plant fails owing to exceptional circumstances in the future, another location can step in. This enables us to work more efficiently and increase productivity,” adds Maia.

First-class industrial belt drive solutions and services

"We want to consistently demonstrate this premium approach to the outside world. In the future, it will be visibly reflected in the appearance of the belts and the naming structure,” says Sascha Heyde, the product manager responsible for belt drive solutions in Continental’s industrial segment. “These are changes, of course. But the same quality standard and people that our customers are familiar with stand behind them. We will all continue to provide the best quality, technology and service to keep our customers’ and partners’ operations running as smoothly as ever. That is why we chose the term ‘continuity’ for our communication approach."

All regions will be using the naming structure by the end of 2023. Maia sums up: “Bringing all products, competencies, innovative technologies and services together under one name is an important step in ensuring the long-term success of Continental and our strategic business partners. And that is the step that we are taking now.”

10 tips you need to know for compressed air savings

Best practices to save compressed air from VPInstruments

Test & Measurement

Almost all manufacturing plants use compressed air. Compressed air takes up 10 to 30% of the electrical bill of an average industrial company. Being significantly costlier than electricity, research has shown that factories can spill up to 50% of their compressed air consumption. There is a considerable amount of compressed air which gets lost due to leakages or inefficient production procedures.

To increase and manage the efficiency of compressed air systems, compressed air savings is crucial and important. By optimizing usage of compressed air and saving on energy and costs, it helps the system become more reliable, sustainable, and productive. In this whitepaper, VPInstruments guides you through the top ten best practices that you can apply right away to save compressed air in your plant.

Industrial Cyber Sec Forum 2023: Protect your Industrial Infrastructure!

This international event dedicated to cybersecurity will take place in the Van der Valk Hotel Nivelles-Sud, Belgium, on February 9, 2023. TIMGlobal Media is media partner.

The occurrence and sophistication of cyber-attacks are evolving at a fast pace. While cybercrime is widely publicized in the world of fi nance and at the states level, industry is also a prime target, since all parts, components, and systems are interconnected through Industry 4.0.

The international survey conducted in 2020 by specialist in cybersecurity solutions and services Fortinet showed that during the past year, 58% of large industrial companies stated they had experienced a security breach in their OT systems. In addition, security specialist Kaspersky reported in a 2020 study that 93% of companies believe their cybersecurity strategy is insufficient. Moreover, the Ponemon Institute’s independent study indicates that 61% of companies said outdated IoT systems were the main obstacle to reducing cyber risks. Last, among a survey of 77 Belgian manufacturing companies made by the trade association Agoria, 55% of respondents say they do not use or consider any standards for IoT cybersecurity. To conclude “the IoT environment is technologically very vulnerable” and “manufacturing companies are generally not able to react adequately to an IoT cyber incident and to recover quickly.”

Industry 4.0, industrial cybersecurity, IIoT, SCADA, PLC, DCS, ICS, edge computing, storage, and more hot topics

In manufacturing companies, computer (IT) networks and industrial operational technology (OT) networks are increasingly merging as a result of the digital transformation. The IT / OT convergence is driving the need to integrate equipment such as programmable logic controllers (PLCs), industrial control systems (ICS), industrial internet of things (IIoT), supervisory control and data acquisition (SCADA) systems and distributed control systems (DCS).

“It is clear that the IoT environment is very vulnerable and that few companies have good visibility of this type of environment. Although budgets allocated to OT security are increasing, awareness and general knowledge of the risks related to the IT / OT convergence are still insufficient,” summarises François Vajda, Managing Director of Mark-Com Event.

Target audience: decision makers in public or private sectors, professional users, B2B actors

To meet these challenges Mark-Com Event announces the Industrial Cyber Sec Forum 2023 to be held on February 9, 2023 at the Van der Valk Hotel in Nivelles-Sud. The goal is to present the IT decision makers and industrial security managers the market situation as well as what is provided by main suppliers. A series of conferences will allow visitors to learn about the latest developments in the field and to answer their questions.

“We will offer both high-level thematic presentations and other presentations from suppliers in the ICT market. At the same time, a special room will enable visitors to discover new technological developments and understand the major issues at stake,” adds François Vajda.

This event is aimed at information and communication technologies specialists as well as those responsible for the operation and security of industrial environments to enable them to understand the latest technological developments.

The Van der Valk Hotel in Nivelles-Sud off ers well-equipped conference rooms, a 500 m2 sponsor area and ample parking.

Optimizing the Application of Adhesives thanks to Cobotics

Meler, HMI-MBS and Universal Robots pool their know-how to offer an adhesive application workshop with the help of a collaborative robot, on January 19 at Meler's Orleans facility.

Industrial Equipment & Supplies

The application of adhesives for every industry represents only a single stage of the production process in many sectors, as a part of the whole. This is why Meler France team, in collaboration with HMI-MBS and Universal Robots, organized a workshop on its premises to show how cobotics could optimized adhesive application at the end of the line.

Stabilisation of pallets with adhesive...and a cobot

The day's programme included a presentation by the organising companies and a live demonstration in which the attendees, with technical profiles from the aeronautics or automotive industries, were able to see the advantages that a collaborative robot can bring to any adhesive application. Sylvain Pitard, Sales Director of Meler's French subsidiary, and Julien Plault, HMI-MBS sales technician, explained two real use cases of adhesive application in palletizing processes, see Figure 1 and Figure 2 (for webmag readers click on the title to see pictures or at this link).

Captions for Figure 1

1. Automatic application of adhesive on the moving box. / 2. Loading of the box and stacking on the pallet with a COBOT. / 3. Formation of a compact batch ready for transport.

Captions for Figure 2

1. Loading of the goods with a COBOT. / 2. Automatic application of the adhesive on the box hold by COBOT. / 3. Moving and positioning of the goods at another point of the working line.

Production and environmental advantages

The logistics sector has been quick to implement the combination of both technologies: cobotics and adhesive application because of the production benefits they bring to the profitability of the end-of-line. Occupational risks related to loading and transporting goods are reduced (Figure 3 - 1) and operators can focus on higher value-added tasks.

However, the interest in introducing these technologies is not just about cost efficiency and safety. By introducing the application of adhesives, the goal is also to eliminate the use of single-use packaging materials (Figure 3 - 2) and achieve excellent results in the unification of goods. This ecological aspect helps continue to driving companies to change their end-of-line installations.

In addition, the Q&A session allowed attendees to benefit from personalized advice in regards with the implementation of new projects. Sylvain Pitard, Sales Director of Focke Meler France, acknowledges his satisfaction as host: "It is exciting to resume the networking activities that are so typical of a sector like ours, where we always work as a team. It is this type of exchange that makes our commercial activity more valuable and we are also proud to have organized it in our Orléans facilities, which were inaugurated in the middle of the pandemic".

What is Digital Twin Technology and Why is it Important for Manufacturers? Virtual Twin Experience

Whilst uptake in smaller manufacturing firms has been slower, automotive and industrial sectors are slowly starting to see the value that digital twin technology can bring, no matter the size of the business.

Automation

3DS Delmia. Digital Twin technology has quickly become a staple with many of the largest manufacturers in the automotive and industrial engineering sector around the world thanks to its ability to provide huge amounts of value in saving time and optimizing plant effectiveness.

What is Digital Twin & Virtual Twin technology?

Digital twin technology allows manufacturers to gain a digital representation of a real-world system – the digital twin mirrors the software or model to gain data and insight that can update

Digital twin is actually an executable model of a physical system. The physical system can be a factory or a plant or a mine or resource any of them. Which brings in learning and experiences from the physical part, so that you can continuously update your distribution model. The next step up from digital twin is virtual twins, which provide a far more dynamic look factory systems. Virtual twins provide businesses with the ability to visualize models and simulate sophisticated experiences—whereas digital twin solutions are static. Virtual twin essentially shows manufacturers exactly what can be executed and implemented in the real world, it’s primary focus is to give actionable solutions to improve efficiencies.

In fact, Virtual Twin technology helps us visualize a model not only of the product, but manufacturing and operations as well. When thinking about the capabilities of digital twins, they operate in a closed loop of “ability to ability”, but virtual twin goes beyond that. It provides the opportunity where you can control the real world with the virtual world with this closed loop ability and we can bring innovation to expand on that. Virtual Twin solutions can be beneficial for almost any manufacturing organization, both small and large. It also empowers workforce of the future, and considering current conditions, it's like bringing in new resiliency while people are working in the new or next normal due to this pandemic.

Which Industries Can Benefit from Digital & Virtual Twin?

Digital twins initially found their way into a select few industries where businesses could easily see value and return on investment. The automotive & industrial equipment sectors were the two main areas that invested in digital twin technology initially, along with oil and gas shortly after. These industries had a clear need for the insights provided by digital twins to streamline processes and provide extra efficiency.

In more recent times, manufacturing and life sciences are beginning to really catch up on the benefits that are brought about by digital twins as they’re really relying on the twins ability to provide sophisticated models that can be acted upon. In manufacturing and the operations industries, the overall goal for most businesses is to achieve greater profitability in a safe and sustainable way.

The length and breadth of industries that can adopt this type of technology stretches far and wide, and the same can be said about virtual twin technology, as this is essentially a step further than the insights offer by digital twins.

Why Are Digital/Virtual Twins So Important for Manufacturers?

There are many benefits to having digital or virtual twins integrated into your workflow as a manufacturing business, though the most pertinent are normally time, cost and resource savings, increased levels of safety for all employees.

In recent years, there’s been an increased focused on sustainable manufacturing and a ‘circular economy’, with real emphasis being placed on improving the overall productivity and safety of processes. Alongside this, there’s been a real shift in manufacturing bosses looking for more control over production, whilst also minimizing costs. All of this is covered by digital/virtual twins, as they give manufacturers access to important information about cutting costs whilst maintaining, and improving, workflows.

Whilst manufacturing and operations industries are becoming ever more complex due to the digitalization and innovation within each sector, so it’s important that things are made as simple as possible. Operation lead times can begin to become longer and longer if inefficiencies in the new workflow aren’t ironed out, and that’s where digital and virtual twin technology comes in to play. Having the insight and agility to make changes in manufacturing is exceptionally important, especially with the supply chain issues that are currently facing the vast majority of manufacturers around the world.

To really emphasize the effectiveness of virtual twin technology in particular, in one case study, DELMIA saw plant effectiveness increase by 250% after the installation of a virtual twin. The twin provided an in-depth analysis of inefficiencies and provided the manufacturer with simulation models that would help to combat those inefficiencies. Alongside this, employee safety and fulfillment rose by 5% in time savings.

In a separate case study, DELMIA saw another company increase on time deliveries by 50% thanks to better planning techniques and technologies. There was also a 50% reduction in lead times, which enabled the company to maintain high levels of orders, whilst shipping a higher percentage out on time to consumers. This is obviously exceptionally important when you consider how consumers are changing their behavior when it comes to reduced lead and delivery times.

In summary, digital and virtual twins are quickly becoming the staple within many industries thanks to the number of benefits they bring to each company. Manufacturing and logistics in particular can benefit from the technologies, thanks to vastly reduced lead times and help when it comes to planning efficiently.

Prashanth Mysore, Strategic Business Development and Industry Marketing Director at DELMIA, part of the Dassault Systèmes Group

Robotics Projects: Software as Key to Success

Since the market for special machine construction cannot implement the flexible automation solution that Primus Präzisionstechnik needs, the team decided without further ado to implement the robotics project itself.

Automation, Sensor Technology

Artiminds. Since its foundation in 1978, Primus Präzisionstechnik in Bückeburg, Lower Saxony, has built up a good reputation as an independent system supplier for efficient drive solutions. The family-managed company employs 110 people who develop and manufacture special gear units with power ratings of up to 100 watts for customers in the automotive sector, building automation and medical technology.

"We are a solution provider," says Managing Director Thorsten Völz. "An idea service provider, in a manner of speaking, with an affiliated production facility with a high production depth. The in-house options comprise of turning, milling, assembly and all associated sub-processes." The company has been practicing the much-vaunted Industry 4.0 for many years now, automating and digitizing as many processes as possible with the aim of maintaining a high level of repeatability and process stability, even for large volumes.

This is the case with a force-controlled pick-and-place and joining process in which small gearboxes are produced from several individual parts for a customer in the automotive industry: The task here is to fit three shafts and five gears into a gearbox housing. Before placement, the individual parts are also greased. Approximately 250,000 of these gearboxes are manufactured by Primus each year - until now manually. "This is a complex application with many process steps and different components that need to be assembled into a gear motor, which is later sealed airtight," Völz tells us. "It is therefore vital that all components are assembled completely and correctly. And this is where, unfortunately, people are sometimes the weakest link." To improve product quality and process stability and reduce costs through better dosing of the grease, Primus decided to automate this production step robotically. "We ultimately failed to have a suitable specialized machine built for this purpose," the Managing Director elaborates. The fault lies in the high number of variants and the fact that the intelligence required for the application was not available for the planned budget. "For a standard application, the perfect machine would have been available to us, producing 100,000 parts in a cycle-optimized manner," Völz recounts. "But then, we wouldn't have had any influence on changes, modifications and the different variants." That was not what Primus wanted. "We had to decide on how to proceed," explains Sascha Schwier, Technical Manager at Primus Präzisionstechnik. "Either we design the system completely for accuracy, or we equip it with intelligence so that we can also use it to manufacture other products and reproduce different process steps." A decision was made in favor of the second option. "Our concern with automation was not about optimizing cycle times, but about increasing process accuracy and achieving stable repeatability. Since we wanted to remain flexible in terms of implementation and hardware selection, we decided to start on a greenfield site and tackle our first robotic cell in-house, although we still lacked previous experience in robotics," the Managing Director sums up.

When the software solution is the key

The team first began by procuring the appropriate hardware. "Using sensor technology, we taught the robot to see and feel," says Völz. Primus equipped the robot with a camera and a force-torque sensor. An individual gripper system was added to handle the gears and shafts. The key to the smooth interaction of all parts was the manufacturer-independent software solution ArtiMinds Robot Programming Suite (RPS). "We were looking for a programming environment so that we wouldn't have to touch the source code directly," says Völz. "In the process, the RPS acted as an interface that couples all the peripherals together."

With the software, even complex sensor-adaptive applications can be easily implemented. Users program the robot using drag & drop from predefined templates - the robot code is written independently by the software. In the process, ArtiMinds RPS ensures seamless integration of online and offline programming. In this way, flexible automation solutions can be created and electrical grippers, force torque sensors, image processing systems and PLC communication can be integrated easily. Schwier explains, "For the process to run robustly, the system must be able to compensate for tolerances independently. The only way to achieve this is through intelligent communication between the components. We have practically built our special machine, yet we can still use it flexibly thanks to the algorithms of ArtiMinds RPS."

"ArtiMinds' software solution was a major building block in realizing our requirements," says Völz. "In a classically programmed environment, we would have needed significantly more test cycles and a significantly longer development period." Primus was particularly impressed by the clear and intuitive programming with the software. "ArtiMinds RPS offers many helpful functions that make work easier, such as the 3D simulation environment or the ability to switch back and forth between online and offline mode depending on requirements," lists Michael Castien, Robot Programmer at Primus Präzisionstechnik. "The very big advantage is that I can use a single platform to harmoniously integrate and control all components and sensors such as robots, cameras, force-torque sensors, grippers and motors in the process. The RPS simplifies this step and provides a uniform programming structure." When it comes to solving tricky challenges, the software can also provide quick and easy help with its wizards. "ArtiMinds RPS is a bulging toolbox, so to speak," says Castien "With the provided tools we were able to quickly and safely reach the desired result, as with the spiral search function for instance." This function block provided in the software’s template library enables the robot to conduct a force-controlled search for the insertion and joining location for the gears and shafts. "When there was no template available for a required function, the ArtiMinds support team quickly helped to find a solution without complications," says Castien.

Analysis, optimization and remote maintenance with ArtiMinds LAR

To keep an eye on the plant during operation, Primus uses another product from ArtiMinds: the Learning & Analytics for Robots (LAR) analysis software. This software provides detailed evaluations and data about the production process. "The information is based on robot movements, force-torque measurements, image processing results or error codes," explains Raimund Hartelt, Senior Business Development Manager at ArtiMinds. "These are collected automatically and stored in the database. Enriched with process information from the RPS templates, Primus can interpret the data in a goal-oriented manner with a direct view on the task to be solved and derive optimizations. Moreover, because different users need different data and KPIs, everyone can tailor their dashboard to their exact requirements."

On one hand, Primus uses LAR for process monitoring and fault detection or analysis, on the other hand also to convert process stability into key figures. "ArtiMinds LAR enables us to take a targeted approach to process optimization and troubleshooting," says Schwier. "This eliminates the need for fishing in the dark." Castien also sees this as a major advantage: "There is always a kind of demonstration effect when troubleshooting. Once you are standing in front of the system, the error no longer occurs. With LAR, I can automatically record all the data and, thanks to the seamless documentation, isolate errors within a short time." In addition, optimization potential that would not be visible to the naked eye can be easily objectified. Castien explains, "We have two robots with the same program. The analysis data from the LAR showed that there are still differences, though, and contrary to our assumption, the two systems don't run the same." Using this data, Castien was able to readjust the precision to within 100ths and, after a few runs, re-evaluate whether or not the changes had the desired positive effect.

Cooperation at an equal level

With the software solutions from ArtiMinds, Primus Präzisionstechnik was in a position to implement that flexible robotic cell that the company needed for the fully automated assembly of the small gearboxes. "We achieved our goal and were able to increase the process quality from about 90 to almost 100 per cent," Völz states with satisfaction. "Furthermore, the system gives us high flexibility since we can adapt it to new tasks or changed conditions without much effort, i.e. reprogram it independently. In addition, the robotics know-how built up as part of the project provides us with a major competitive advantage!" The gear specialists were also impressed by the trusting cooperation at eye level. "We grew together on the tasks," says Castien. "When there were challenges, we worked out solutions and ways in partnership. And we still have intensive exchanges, for example, to extend the preparation of LAR's analysis data to our needs, as we are currently doing."

Silke Glasstetter, Head of Marketing at ArtiMinds Robotics

ODVA Conformance Testing Available for ETHERNET/IP Devices on the ETHERNET-APL Physical Layer for Process Automation

At SPS 2022, ODVA presented the availability of complete EtherNet/IP over Ethernet-APL conformance testing as the final step to make the benefits of Ethernet available at the field level in the process industries.

Presented during the SPS 2022 fair in Nuremberg, ODVA announced that conformance testing is now available for EtherNet/IP network-enabled devices that communicate over the Ethernet-APL physical layer. Conformance testing verifies the Ethernet-APL physical layer functionality by checking that the different port types properly adhere to the relevant specifications. The EtherNet/IP communication network functionality is also confirmed as a part of this process. Together, both tests ensure maximum interoperability between vendors as well as different types of instruments and infrastructure components. The availability of complete EtherNet/IP over Ethernet-APL conformance testing is the final step for ODVA to make the benefits of Ethernet available at the field level in the process industries.

Ethernet-APL is the new intrinsically safe, two-wire, Single Pair Ethernet (SPE) solution, based on an extension of 10BASE-T1L (IEEE 802.3cg2019), that meets the requirements of the process industries. The advantages of Ethernet-APL include significantly faster communication speeds of up to 10 Mbit/s, hazardous area protection, power to field instrumentation, and long cable runs of up to 1,000 meters (IEC 61158). Ethernet-APL devices adhere to IEC TS 60079-47 (2-Wire Intrinsically Safe Ethernet) in order to ensure “intrinsically safe” ignition protection.

Taking advantage of the new markets and applications brought by Single Pair Ethernet (SPE)

EtherNet/IP over Ethernet-APL conformance test orders are ready to be placed now. Vendors are invited to place their test orders on ODVA’s website. The physical layer testing covers IEEE data, 10BASE-T1L, and Ethernet-APL port profiles power requirements. This includes EMC testing that aligns with IEC/EN 61326 and NAMUR NE 21. EtherNet/IP network conformance testing covers communication functions defined above layer 2 of the OSI model, and relies upon ODVA’s standard, highly rigorous process. Also, note that intrinsic safety and/or functional safety certification are taken care of by separate safety testing agencies.

“ODVA is focused on expanding the capabilities of EtherNet/IP by taking advantage of the new markets and applications that Single Pair Ethernet (SPE) has opened up. Ethernet-APL is purpose-built to meet the needs of the process industries, which will enable Ethernet-based control and commissioning at the field level and enhanced field to cloud connectivity,” said Dr. Al Beydoun, President and Executive Director of ODVA. “EtherNet/IP is a complete industrial communication network that encompasses discrete, hybrid, and process applications. Recent efforts of joining the Process Automation Device Information Model (PA-DIM) collaboration and the availability of Ethernet-APL testing reinforce ODVA’s commitment to meet the full requirements of the process industries.”

Latest version of The EtherNet/IP Specification including EtherNet/IP for Ethernet-APL

Vendors are now able to bring ODVA CONFORMANT™ products for EtherNet/IP to the market that can function on the Ethernet-APL physical layer. End users will soon be able to take advantage of the benefits of Ethernet at the field level of the process industries, which include significantly faster commissioning time, multiple process variables within one device, and advanced diagnostics and prognostics for failure detection. Additionally, the Ethernet-APL physical layer transports application-layer safety and security services such as CIP SafetyTM and CIP SecurityTM, which utilize IEC 61508 and ISA/IEC 62443 standards.

A thorough testing process helps vendors to be able to offer higher performance products with less potential to cause issues when they are installed at the point of use. Third-party verification in the form of conformance testing is a valuable step in the product development process that ensures a superior vendor product and the best possible end user experience through confirming that the required parameters in the specification are met.

Siemens at the SPS Nuremberg 2022: An Hybrid Press Event

Under the motto "Make it real", Siemens presented on how the real and digital world can be combined so that companies become Digital Enterprises.

Automation

The main topics discussed were the presentations of current business cases, new products for intelligent manufacturing as well as the future of industry with the Siemens Xcelerator. In the run-up to the press conference, Siemens offered an exclusive, guided tour of the Siemens booth.

"With Totally Integrated Automation, we started 25 years ago integrating the OT world and opening it up to IT applications. Siemens Xcelerator further accelerates IT/OT integration, making it the next big vision for industrial transformation. We're bringing IT and OT together more seamlessly than any other company, making industrial processes simple, open, flexible, and sustainable," said Rainer Brehm, CEO Factory Automation of the Siemens AG at the press conference on SPS 2022.

Siemens Xcelerator - what is it about?

With Siemens Xcelerator, the company provides a new digital business platform. This enables customers of all sizes in the fields of industry, buildings, grids, and mobility to accelerate their digital transformation and increase value creation. The new business platform is characterized by simplicity, flexibility, and openness. Everything is geared to the overarching goal of making the digital transformation of companies easier, faster, and scalable. In this context, Siemens Xcelerator consists of three pillars:

Portfolio: the new platform offers a curated, modular portfolio of software and IOT-enabled hardware built on standard application programming interfaces and including a variety of services from Siemens and certified third parties.

Ecosystem: Siemens offers a growing ecosystem of partners.

Marketplace: this facilitates interactions and transactions between customers, partners, and developers.

Sustainability in Industry

Sustainability is becoming increasingly important in industry. At SPS, Siemens showed how companies are implementing their sustainability goals while remaining profitable.

With SiGREEN Siemens offers companies the basis for targeted emission management and so the opportunity to effectively pursue their decarbonization goals on the product level. SiGREEN thus provides an answer to the increasing demand for transparency regarding the products’ carbon footprint (PCF).

Electric motors are responsible for over 70% of industrial energy demand. Siemens is aware of this issue. With energy-efficient drive systems, energy savings of up to 60 % can be achieved in the overall system.

Inovance Launches PLC, Servo Drives, & Motion Controllers at SPS 2022

Attending the SPS Nuremberg trade show for the first time, Inovance Technology Europe presents the European face of a fast-growing $3 billion industrial automation company, through four new products.

Automation, Motors & Drives

At SPS 2022, Inovance Technology Europe, the Stuttgart-based European arm of global industrial automation company Inovance, announced the launch of four new products for the European market: the high performance Easy Series PLC, the GL20 I/O modules, the AC703 IPC motion controllers, and the SV670 servo series. The company also re-presented the MD800 compact AC drive which has never before been seen at the SPS show, and gave an advanced preview of the SV680 servo drive.

The hidden champion

At the SPS in-person press conference, Inovance first reported about its rapid growth, both globally and in Europe, revealing that global sales have hit $3 billion over the last three years. The company then showed how they have invested significantly in Europe for the long-term. Benefetting from a wide team in Europe, the company spreads across an office network that includes Stuttgart (the European HQ), Bordeaux, Milan, Istanbul, and Barcelona, as well as a network of European distributors. Looking at its Stuttgart HQ, Inovance has important R&D facilities for the development of real-time machine control software. Additionally the company has employed a team of product managers who work closely with OEM customers to understand and define the optimal solution for their needs, alongide with a strong team of European applications engineers to advise and support customers.

A complete motion solution package

Inovance's complete motion solution package includes motion controllers, servo drives with EtherCAT and servo motors, HMIs, and LV and MV AC drives. Showcased during SPS, the four new products were: the Easy Series PLC, the GL20 I/O modules, the AC703 IPC motion controller, and the SV670 servo drive. The Easy Series is a high performance, compact, EtherCAT-enabled PLC. The highly compact GL20 I/O modules are 2/3 smaller than Inovance’s previous generation product, and offer a minimum cycle time of 125 microseconds. The AC703 IPC motion controller offers a CODESYS (IEC 61131-3) programming environment, up to 32 axes control, a Webvisu server, EoE support, IIoT capability and safe shut-down (without the need for an additional UPS). Finally, the SV670 single-axis pulse servo drive offers high performance, enhanced functionality, and true flexibility.

Meanwhile, alongside the product launches, Inovance offered a preview of the SV680 servo drive with advanced functional safety functions - including FSoE, and extremely high performance, and also presented the MD800 AC multidrive at SPS for the first time. While MD800 was launched late last year, it has never been seen at the Nuremberg show until now due to last year’s cancellation. MD800 is a compact AC multidrive that is designed to answer the call of European OEMs for reduced installation costs and smaller machine cabinets.

David Bedford Guaus, Strategic Marketing Manager for AC drives and servos at Inovance Technology Europe, says: “It is a very exciting time for Inovance Technology Europe right now. With the resources of a $3 billion global corporation behind us, we are investing heavily in Europe for growth, and are constantly winning new customers and recruiting new staff. Unlike many drives and automation companies at the moment, we are able to supply product immediately and with very short lead times.”

“There are two things that are particularly exciting about Inovance for me: one is the chance to play a big part in building a pan-European company from the ground up. The other is our product range. We have one of the most complete product ranges of any industrial automation company, as reflected in the fact that, in 2021, we invested 9.4% of revenues, and fully 20% of our global headcount, into R&D. Our product range includes: LV and MV AC drives, servos, motion control, PLCs, HMIs, CNCs, and industrial and SCARA robots”.

Easy-to-use, high stability Optical Mounts

Designed to mechanically support parabolic, spherical, and flat mirrors from 100 to 600mm in diameter

Vision & Identification

Employing high precision optics in applications where optical stability is critical is pointless unless they are positioned with absolute precision and stress-free. To fulfil this need, Optical Surfaces designed the OS Series of optical mounts to overcome the ease of use and poor performance shortfalls of many general-purpose mounts.

For smaller diameter mirrors (100 – 254mm) a choice of four models of OS Mounts provide a secure and stable platform for your optical experiment. Two-axis angular alignment can be quickly achieved by means of dual action adjusters with fine screw and ultra-fine differential micrometre action. Using these mounts, you can rapidly align a mirror within a few arc seconds. Each mount comes with a baseplate to facilitate rapid and simple mounting onto an optical table or other experimental platform.

Trouble-free operation

For secure and stable positioning of larger diameter mirrors (305 – 550mm) – Optical Surfaces offers four standard OS Series mounts. Angular alignment of larger diameter mounted mirrors is achieved about the vertical and horizontal axes over a wide range of angles. Using these mounts, it is possible to rapidly align a large diameter mirror within a few arc seconds. Each OS 300-600 mount comes with adjustable feet to facilitate rapid and simple mounting onto an optical table. A range of additional motorised options are available for OS 300-600 series mounts, for instance to facilitate remote operation in hostile environments or for use in limited space applications where manual adjustment may be difficult.

Flow Sensing Challenges in Food & Beverage Production

Titan Enterprises offers a range of high-performance flowmeters in food grade materials where both food hygiene and precision flow measurement are required.

Sensor Technology, Test & Measurement

Flow measurement is a critical tool for food and beverage manufacturers, the industry having a diverse range of processes that require the precise control of liquid flow rates. Production processes including filling of vessels or bottles, measuring liquid ingredients, and controlling cleaning processes, require varying degrees of complexity and accuracy to ensure consistent product yield and minimise wastage. Although there are a wide variety of general flowmeters on the market, only a few high-performance measuring devices will ensure the high levels of hygiene and precision are maintained for applications in the food and drinks sector.

“The physical properties of the liquids themselves lend additional complexities to the choice of flow measuring equipment,” says Neil Hannay, Senior Development Engineer at Titan Enterprises. “Consideration of whether the liquid is viscous, volatile, corrosive, flammable, or contaminated with particles, for example, or needs to be maintained at a high temperature, are key factors in deciding a suitable flow meter.”

Monitoring Flow of High and Low Viscosity Fluids

Flow monitoring of high viscosity liquids, such as cooking oils, sauces and syrups (e.g. syrup injections in beverage lines) require devices such as Titan’s oval gear flowmeters, which provide highly accurate flow measurement. Unlike other flowmeters, measurement accuracy of oval gear flowmeters improves as the liquid viscosity increases, from a nominal 1% to around 0.1% of flow rate at higher viscosities.

Whereas for low viscosity liquids such as water, beer, wine and spirits, Titan’s NSF-approved 800-series and beverage flowmeters provide a low-cost drink dispensing solution. Designed to give high performance over 6 flow ranges from 0.05 to 15 l/min, these devices have totally non-metallic NSF-approved wetted components making them ideally suited for applications where both food hygiene and precision flow measurement are required.

Flow Monitoring at High Temperatures

In processes where ingredients need to be maintained at high temperatures – chocolate for example – a flowmeter designed for applications requiring precise flow measurement at elevated temperatures would be needed. Capable of operating up to 110°C, Titan’s inline non-invasive Atrato® ultrasonic flowmeter is largely immune from viscosity and offers excellent turndown and repeatability.

Titan Enterprises offers a range of oval gear flowmeters in food grade materials for viscous products such as sauces, oils and syrups, as well as NSF-approved mini-turbine flowmeters for drink dispensing. As an experienced OEM supplier, Titan develop customised flow meters for specific customer applications within the food and beverage industry.

Single-pair Power over Ethernet (SPoE) Solutions for Smart Building and Factory Automation

Analog Devices announces world’s first long-reach, SPoE Solutions to help customers drive greater levels of intelligence into smart buildings, factory automation, and other applications at the edge of traditional networks.

Automation, Electronics & Electricity

Analog Devices announced the world’s first Single-pair Power over Ethernet (SPoE) Power Sourcing Equipment (PSE) and Power Device (PD) solutions. The new offerings facilitate powered, last-mile connectivity for factory and building automation through real-time power management, telemetry, extremely low standby power consumption, and ease of installation.

“The Intelligent Edge is one of the most exciting developments of the digital era as computing power is pushed to previously inaccessible applications and locations,” said Leo McHugh, Vice President of Industrial Automation at Analog Devices. “Analog Devices is committed to delivering the unrivaled technology and solutions our customers need to leverage the full potential of the Intelligent Edge in smart buildings and factories as well as many more applications in the future.”

Enabling Digital Buildings of the Future

Analog Devices’ new SPoE solutions, LTC4296-1 and LTC9111, address the challenges of providing power and data to devices, even in remote, difficult to access endpoint locations. Analog Devices’ solutions aim to help new families of endpoint applications to be seamlessly powered and accessed across the network and used to assess local factors such as asset health, environmental conditions, security metrics, and more. The localized awareness and control they offer are the building blocks of the digital buildings of tomorrow.

Analog Devices’ SPoE solutions reduce reliance on localized power and batteries by using a single twisted pair of Ethernet cables to provide efficient, reliable, easily installed power at reduced size and weight. Combined with ADI Chronous™ ADIN1100 and ADIN1110 10BASE-T1L, Industrial Ethernet solutions, customers can reliably transfer both power and data over one kilometer – a significant increase from previous Ethernet standards.

Interoperable Efficiency

Analog Devices’ new LTC4296-1 5-port SPoE PSE with Classification and LTC9111 SPoE PD with Polarity Correction products support both SPoE and Power over Data Line (PoDL) variants of single-pair powering. SPoE augments Single Pair Ethernet (SPE) to provide more reliable, fault-tolerant, and interoperable point-to-point power solutions, delivering up to 52W. Both products are 802.3cg compliant and support Serial Communication Classification Protocol (SCCP).

The trend in the TFT display sector is towards ever higher resolutions and Full HD is increasingly being replaced by 4K or 8K. The LVDS interface is not well suited for the transmission of such large amounts of data. With the new “BoxPC Pro NPA-2009”, Distec offers a novel docking connector for direct connection of high-resolution V-by-One and/or eDP TFT displays. It is based on an industrial mainboard with the Intel® Core™ i embedded processor i5-1145G7E of the 11th generation.

24/7 operation in industrial and low-cost applications

Optionally, the NPA-2009 is also available with the Core™ i7-1185G7E or Celeron® 6305E processors on a project basis. All Tiger Lake processors feature high frame rates, economical power consumption and low latency and are suitable for continuous 24/7 operation. It is ideal for applications that require high-resolution displays with a high frame rate and high color depth, including info terminals, medical technology, and transportation.

24/7 Robotic System

Suitable for CNC machine, compatible with all robot brands, can be moved to any part, can be loaded and unloaded on more than one machine

Automation

Tezmaksan's RPA (Robotic Process Automation) system CUBEBOX brings profitability, efficiency and performance. CUBEBOX can help make savings and increase productivity by up to 50 percent in night shifts as it can work 24/7 without an operator. With its compact and ergonomic structure, the device can be positionned wherever the user want.

Ideal for uninterrupted and practical work

CUBEBOX's pallet changing feature allows the operator to load and unload the magazine "without interrupting the robot working with the machine". The system, which can adapt to every work piece, meets every business-specific needs with its three main and seven sub-models. CUBEBOX is a unique system that can easily define automation processes and use them without the need for program knowledge, thanks to the ROBOCAM program coming with a user-friendly interface.

In addition, CUBEBOX uses less resources, energy and labor. Thus, the user both minimizes costs and protects the future of our planet by minimizing their carbon footprint.

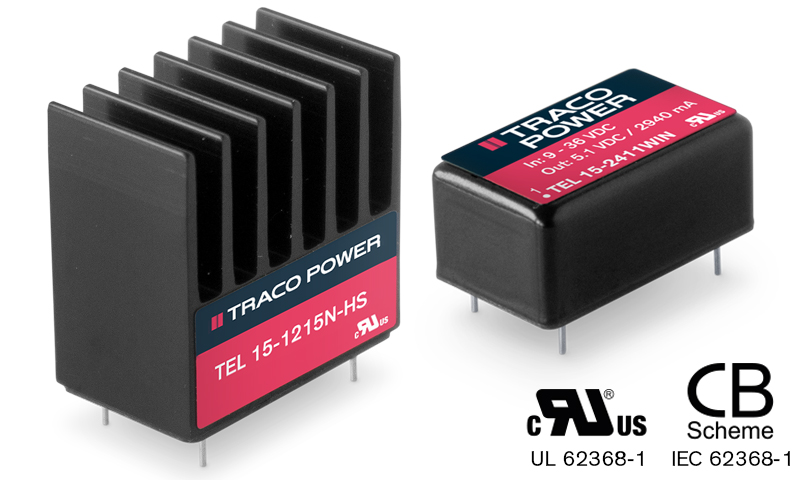

Ultra Compact 15 Watt DC/DC Converters (DIP-16) for Industrial Applications

Highest power density of 4.51 W/cm3

Electronics & Electricity

Traco. The TEL 15N & TEL 15WIN are two series of isolated 15 Watt converters which come in an ultra compact DIP-16 metal package. The design purpose of these series was to miniaturized low power DC/DC converters to the maximum without sacrificing high efficiency. They solidify the new standard for power density with 4.51 W/cm3 and effectively double the power density compared to 15 Watt converters in DIP-24 packages.

High efficiency (up to 88%) for low thermal loss

The TEL 15N and TEL 15WIN offer wide 2:1 or 4:1 input voltage ranges respectively and feature a high efficiency of up to 88% which enables an operation temperature of up to +55°C at full load and up to 85°C with 50% load. For extended temperature requirements, a version with a fully integrated heatsink casing is available allowing the converter to operate up to +70°C without derating. The converters also have an internal input filter to comply with conducted emission standard EN 55032 class A. Overall they feature an economical solution for space critical and cost sensitive applications in instrumentation, IT and industrial electronics.

Space-ready Optics for Micro and Nanosatellites

Meet the very strict requirements for a lens or optical system to be considered space-ready in a growing range of applications including remote sensing or surveillance

Sensor Technology, Vision & Identification

Resolve Optics is a leading provider of miniature space-ready optics that lie at the heart of microsatellites and nanosatellites being deployed for a growing range of applications including remote sensing, earth observation, data communications, scientific analysis, and surveillance.

For a lens or optical system to be considered space-ready it must meet some very strict requirements. The key environmental considerations when designing lenses for use in satellites includes how they react to the vibration and shock of launch, extremes of temperature, high vacuum and cosmic radiation encountered in space.

Adapted optics to smaller and smaller satellites

Mark Pontin, Managing Director of Resolve Optics commented “As satellites have decreased in size there is the necessity for the optics that lie at the heart of these imaging platforms to also reduce in size and weight. This is not always a straightforward task. If you are developing a camera system for a micro- or nanosatellite-based space mission, we recommend incorporating a compact sensor and then it will be possible for us to keep the lens design compact as well. Being able to keep the size of the lens compact also helps them withstand vibration and shock during launch into space as the mass is small. To ensure your micro- or nanosatellite optics are sufficiently robust, all elements in our space-ready optics are secured and unable to break loose when subjected to the rigours of launch and other environmental factors. All our satellite lenses and optical systems are athermalized to ensure they maintain focus throughout the wide operating temperature range typically experienced in space. The impact of cosmic radiation on your lens or optical system is a major consideration when designing for use in space. Unfortunately, standard optical glass types turn brown or grey when exposed to cosmic radiation. As a result, the light transmission of the lens will degrade markedly in just days or weeks. For longer term space missions, we use cerium doped glass elements that prolong the life of the satellite lens or optical system to years.”

869 MHz Compact UHF Transmitter and Receiver

Simple, high-quality radio module that allows radio communication using user-specific protocols, without having an embedded communication protocol

Electronics & Electricity

Circuit Design, Inc., specialist of low power radio modules, announces the release of 869 MHz models of the compact UHF transmitter (CDP-TX-07MP) and receiver (CDP-RX-07MP).

The compact narrow band radio module CDP series has been highly regarded since the first generation model for industrial radio applications, including remote control, and is a long-selling model that has been supplied for over 20 years.

Simple, easy-to-use interface, allowing the use of user-specific protocols

The CDP series provides stable communication even in poor radio communication environments, thanks to narrow band communication and a receiver with high selectivity and blocking performance.

The CDP-07 model is the most compact model in the series. It is pin compatible and communication compatible with the previous models CDP-TX-05M-R / CDP-RX-05M-R. The smaller size and lower profile of the internal components have resulted in a 25% reduction in transmitter volume (compared with previous models).

An addtition to the 434 MHz versions

CDP-07MP models can have their preset frequency channel tables rewritten by a dedicated configuration program (Pictures 2-3). In the 869 MHz versions, you can select and set 4 channels from among the 155 channels (in 12.5 kHz steps) from SRD 868 to 870 MHz. The required frequency can be selected in the 869 MHz band (Picture 4) where sub-bands are specified by the application. The four preset channels can be selected from either solder jumpers or pins on the board.

Circuit Design maintains the interface while updating the internal radio circuitry and electronic components to ensure the long-term stable supply required for industrial equipment.

TIMGlobal Media, Pioneer of Specialized Technical Information in the Industry

TIMGlobal Media, which notably publishes IEN Europe and PEI in France, was hosted by French business TV channel BFM Business on Wednesday, November 9, 2022. Discover the video of the interview which were broadcast on this opportunity.

TIMGlobal Media, which notably publishes IEN Europe, and PEI in France, was the guest of French TV channel BFM Business this Wednesday, November 9, 2022.

As a European press group specializing in the industry, TIMGlobal Media aims to connect suppliers and buyers through the entire industrial purchasing process, while providing up-to-date information and adapting to the digital era.

Through the trend towards digitization, the use of social networks and webinars allow you to communicate better by relying on our very large database of nearly 350,000 GDPR-compliant subscribed users.

Through the information we provide, we strive to anticipate technological and social developments and present them to you so that you can take them into account in your strategy.

Thanks to our 77 annual printed and digital issues, 6 million page views on 12 websites and 900 newsletters, we provide you all the essential communication vectors to promote your products and your company. Discover the article dedicated to us by BFM Business as well as the video of the interview by clicking on this link.

Media Kit 2023 Click here

Free Digital Subscription Click here

TIMGlobal Media BV

Rue de Stalle 140 - 3ième étage - 1180 Uccle - Belgium

o.erenberk@tim-europe.com - www.ien.eu

- Editorial Director:Orhan Erenberko.erenberk@tim-europe.com

- Editor:Kay Petermannk.Petermann@tim-europe.com

- Editorial Support / Energy Efficiency:Flavio Steinbachf.steinbach@tim-europe.com

- Associate Publisher:Marco Marangonim.marangoni@tim-europe.com

- Production & Order Administration:Francesca Lorinif.lorini@tim-europe.com

- Website & Newsletter:Marco Prinarim.prinari@tim-europe.com

- Marketing Manager:Marco Prinarim.prinari@tim-europe.com

- President:Orhan Erenberko.erenberk@tim-europe.com

Advertising Sales

Tel: +41 41 850 44 24

Tel: +32-(0)11-224397

Fax: +32-(0)11-224397

Tel: +33 1 842 00 300

Tel: +49-(0)9771-1779007

Tel: +39-02-7030 0088

Turkey

Tel: +90 (0) 212 366 02 76

Tel: +44 (0)121 705 21 20

John Murphy

Tel: +1 616 682 4790

Fax: +1 616 682 4791

Incom Co. Ltd

Tel: +81-(0)3-3260-7871

Fax: +81-(0)3-3260-7833

Tel: +39(0)2-7030631

- WebMag IEN Europe July 2024 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- IEN Europe May 2024 IEN Europe presents Industry News, Products and Solutions for industrial decision makers in the pan-European B2B market.

- WebMag HANNOVER MESSE 2024 Special issue for Hannover Messe 2024, April 21 - 26

- WebMag January/February 2024 IEN Europe presents Industry News, Products and solutions for industrial decision makers in the pan-European B2B market.

- WebMag December 2023 Highlights Products and Solutions sps and from 2023

- IEN Europe November Webmag Special SPS As the industrial world gears up for the 2023 SPS Show in Nuremberg, attendees and exhibitors alike are eagerly awaiting the opportunity to delve into the latest trends and innovations that promise to reshape the future of industrial automation and techno

- IEN Europe April WebMag Throw an eye to this web magazine dedicated to the coming Hannover Messe 2023! We wish to see you there as well. Have a nice and interesting reading

- IEN Europe Jan/Feb 2023 Webmag Dear readers, Happy New Year to you! IEN Europe is coming back this new year with a special focus on robotics and digital automation.

- #6 AI IEN - December 2020 Discover our latest edition of our digital magazine: AI IEN!

- IEN Europe December Last issue of 2020, IEN Europe December highlights the key trends in the IoT & e-mobility, Automotive, and Identification & Vision Systems fields.

- IEN Europe November - SPS Webmag Discover in this digital issue the best technology showcased at the upcoming SPS virtual exhibition!

- #5 AI IEN - October 2020 We are delighted to release the fifth issue of AI IEN! With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.

- Covid-19 Special e-magazine Don't miss our new issue on Covid-19 to discover the most innovative Industrial answers to the pandemic.

- #4 AI IEN - June 2020 Don’t miss the fourth issue of AI IEN! With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.

- #3 AI IEN - April 2020 Don’t miss the third issue of AI IEN! With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.

- #2 AI IEN - February 2020 Don’t miss this new issue of AI IEN! With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.

- SPS Webmag November Discover in this digital issue the best technology showcased at the upcoming SPS - Smart Production Solutions 2019!

- #1 AI IEN - September 2019 We are delighted to announce the launch of our new digital magazine AI IEN. With a specific focus on Artificial Intelligence (AI) applied to the industrial field, AI IEN aims to become a point of reference for all AI professionals.