Quick access

Contents2 Industry News: Nord | Joint Standard for Energy Management | Endress+Hauser3 Industry News: QT GROUP | AI for Advances Materials Design Wins Manchester Prize4 Industrial News: Canton Fair | Altair5 Industry News: ABB Robotics | Pepperl+Fuchs6 Safety & Security: Certified Components: A Strategic Advantage in Cybersecurity8 Safety & Security: Virtual Model for Safety Planning for Production Environments9 Safety & Security: SICK | MyScada10 Safety & Security: As Geopolitical Tensions Rise AI Is Amplifying the Threat of Global Cyberwarfare11 Safety & Security: Murrelektronik | Schmersal12 Automation: MES Is Not Rocket Science if You Treat It Right13 Automation: Beckhoff | VPInstruments14 Electronics & Electricity: Harting | Autronic | ITEN15 Sensors, Test & Measurement: FLIR | Amsys16 Sensors, Test & Measurement: ifm | Optris17 Sensors, Test & Measurement: LIKA | WIKA18 Industrial Equipment: Aerzen | Pfeiffer19 Energy Efficiency Business & Industry: Decarbonisation: How Filtration Play a Key Role in Transforming Captured CO2 Into a Value Stream20 Index21 Contacts22Companies in this issue

ACE Stoßdämpfer GmbH7 Balluff GmbH18 Lika Electronic Srl18 Optris GmbH & Co. KG17 VPInstruments14ACE Stoßdämpfer GmbH7 Aerzener Maschinenfabrik GmbH19 AMSYS GmbH & Co. KG16 Armis11 Autronic GmbH15 Balluff GmbH18 Beckhoff Automation GmbH14 Cleanova20 Critical Manufacturing13 FLIR SYSTEMS TRADING BELGIUM16 HARTING KGaA15 ifm electronic gmbh17 ITEN SA15 K.A. Schmersal GmbH & Co. KG12 Lika Electronic Srl18

#2 Contents

#3 Industry News: Nord | Joint Standard for Energy Management | Endress+Hauser

#4 Industry News: QT GROUP | AI for Advances Materials Design Wins Manchester Prize

#5 Industrial News: Canton Fair | Altair

#6 Industry News: ABB Robotics | Pepperl+Fuchs

#7

#8 Safety & Security: Certified Components: A Strategic Advantage in Cybersecurity

#9 Safety & Security: Virtual Model for Safety Planning for Production Environments

#10 Safety & Security: SICK | MyScada

#11 Safety & Security: As Geopolitical Tensions Rise AI Is Amplifying the Threat of Global Cyberwarfare

#12 Safety & Security: Murrelektronik | Schmersal

#13 Automation: MES Is Not Rocket Science if You Treat It Right

#14 Automation: Beckhoff | VPInstruments

#15 Electronics & Electricity: Harting | Autronic | ITEN

#16 Sensors, Test & Measurement: FLIR | Amsys

#17 Sensors, Test & Measurement: ifm | Optris

#18 Sensors, Test & Measurement: LIKA | WIKA

#19 Industrial Equipment: Aerzen | Pfeiffer

#20 Energy Efficiency Business & Industry: Decarbonisation: How Filtration Play a Key Role in Transforming Captured CO2 Into a Value Stream

#21 Index

#22 Contacts

60 Years of Driving Businesses

G. A. Küchenmeister and Günter Schlicht founded NORD DRIVESYSTEMS on 1 April 1965. Since then, the family business has evolved into an important system provider for mechanical and electronic drive technology with more than 4,800 employees worldwide.

60 years of NORD – this milestone is a special one. The company is characterised by long-term experience, extensive know-how in more than 100 industries, own production facilities, great production depth, and a global network. Thanks to its qualified employees, NORD can provide its customers worldwide with individual drive solutions from a comprehensive range of modular products and high quality standards.

Company history in retrospect

After the foundation in 1965, today’s Zahnradwerk NORD was built in Glinde in 1977 for the manufacturing of gear components. In 1979, the first foreign subsidiaries have been founded in the USA, France and Sweden. Today, NORD serves the international market with 48 of its own subsidiaries in 36 countries and further sales partners in more than 50 countries. This allows for service, advice, storing and assembly directly on site – always close to the customers.

NORD has expanded its production by in-house manufacturing of electric motors, and shortly afterwards started the production of electronic components in Aurich. Due to the high demand, the NORD Electronic Drivesystems subsidiary in Aurich, Lower Saxony, has grown ever since. In 1991, Fertigungstechnik NORD was founded in Gadebusch – a plant for machining for the manufacture of housings and shafts. The plants in Germany, Italy, Poland, the USA and China are steadily expanded and modernised. The headquarters in Bargteheide, where a modern administration building has recently been built, is also in continuous development.

Technological highlights

In 1981, NORD has developed the UNICASE™ housing concept, a groundbreaking invention for the industrial production of gear unit housings, which is still international standard. In 2000, the focus was on the product launch of decentralised drive technology.

Innovations pay off

Just before the turn of the years 2022/2023, NORD passed the one billion euro sales threshold for the first time in the company's history. This shows, how well the manufacturer’s drive solutions meet the requirements from different industries and how much NORD is appreciated as a strong and reliable partner – expressed in 2023 by the company’s claim “Our Solution. Your Success.”

Outlook after 60 years

2025 will be a very special year for the NORD DRIVESYSTEMS Group: For more than 60 years, NORD has been representing reliable and innovative drive solutions. Despite the current economic challenges and uncertainties in the global markets, the company looks ahead confidently. Innovative drive solutions, industry expertise, international orientation, high quality standards and a strong global network form the basis for sustainable growth. The anniversary is not only a reason to celebrate but also an incentive to further set new industry standards and to further convince customers with powerful solutions.

Innovative Standard for Optimization of Industrial Energy Savings

Accurate energy consumption data is essential for companies aiming to achieve climate-neutral production. To support this goal, a consortium of organizations has recently published a groundbreaking specification for interoperable and efficient energy management in industrial and process automation.

A key goal of the mechanical and plant engineering industry is to achieve climate-neutral production in the future. This effort is supported by the European Union’s European Green Deal, which aims to make Europe climate-neutral by 2050. In order to achieve this goal and implement many other use cases, accurate data on energy consumption in production is crucial. The consortium, consisting of the organizations ODVA, OPC Foundation, PI and VDMA, has now jointly published version 1.0.0 of their groundbreaking specification for interoperable and efficient energy management in industrial automation and process automation. This group is chaired by the VDMA.

Dietmar Bohn, Managing Director of PI, explains: “The measurement and analysis of energy consumption in machines and systems is an extremely important topic for the future. We are pleased to make an active contribution to this important initiative to optimize energy consumption and thereby reduce the harmful effects on the environment caused by waste and surplus.”

Standardized information model based on OPC UA

This specification defines a standardized information model based on OPC UA that enables comprehensive energy management in industrial automation. “This Power Consumption Management collaboration ensures that end users have a highly standardized and interoperable means of achieving their environmental, social and governance (ESG) goals,” explains Dr. Al Beydoun, President and CEO of ODVA.

The introduction of this standard will make energy management in industry considerably easier: companies can now record, analyze and use precise and consistent energy data even more efficiently in order to further increase their energy efficiency. This not only helps to reduce operating costs, but also to reduce the ecological footprint. Standardization makes it possible to implement innovative technologies and best practices faster and more effectively, which contributes to more sustainable and environmentally friendly production in the long term.

Monitoring and standby management: core content of the new specification

The specification essentially comprises two main content fields: Firstly, monitoring, i.e. the display of all types of energy consumption, including electrical energy as well as energy from air, water or coal. Secondly, standby management, which is understood to mean the control and display of various energy-saving modes on machines and components. It is based on the results of the research project “Development of energy management interfaces for IoT technologies (IoTEnRG)”. “The aim of the IoTEnRG research project was to make the results available to industry. We were able to contribute our results directly to the Joint Working Group and thus significantly accelerate the development of the OPC UA Companion Specification,” says Prof. Dr. Niemann from the Institute for Sensor Technology and Automation at the University of Applied Sciences and Arts in Hannover.

“For digitalization, we need an agreement on a common understanding and description of data, including in the energy sector. OPC UA provides exactly that. I am proud that with this joint group, we can also contribute to the energy transition and thus promote optimized energy savings through standardized and efficient monitoring,” says Stefan Hoppe, President of the OPC Foundation.

Machinery Building Block: A step towards climate-neutral production

The VDMA has defined a fundamental standard for the entire mechanical and plant engineering industry, known as “OPC UA for Machinery”. Various functional building blocks are specified in this standard. A new building block for energy management is being developed based on the publication. “The four organizations have been working hard to harmonize and standardize information on energy consumption in manufacturing. This is an excellent first step towards defining an upcoming OPC UA Building Block for mechanical engineering that will bring the machine and plant manufacturing industry a big step closer to the goal of climate-neutral production,” says Andreas Faath, director of the VDMA Machine Information Interoperability department.

Endress+Hauser With an Overall Positive Performance in 2024

The measurement technology and automation solutions specialist increased its sales, created new jobs worldwide, invested more than at any time in its history and maintained profit stability.

The past year was shaped by global crises and political conflicts, making for patchy economic conditions. “2024 was a year of many challenges,” CEO Dr Peter Selders commented at the company’s annual media conference in Reinach, Switzerland. “While Endress+Hauser did not meet all its targets, the company held up well. We made important progress in many areas and have taken our company forward.”

Small and medium-sized markets enable growth

The Group grew its net sales by 0.7 percent to 3.744 billion euros. Organic growth – without currency effects – was 1.3 percent, CFO Dr Luc Schultheiss reported. “The hoped-for economic upturn in the second half of the year failed to materialize,” he said. Sales in all three of the Group’s major markets – the USA, China and Germany – were subdued. This was offset by the company’s small and medium-sized sales centers.

In Europe, sales were down 0.9 percent, mainly as a result of declining numbers in Germany. On the other hand, various individual markets on the continent, including Italy, France and the UK, performed well. Asia as a whole was down 1.9 percent – a result of flagging sales in China. India and Japan, meanwhile, delivered good growth.

In the Americas, Endress+Hauser achieved a 4.2 percent increase in sales overall, driven mainly by growth in Canada, Argentina and Brazil. The USA was only a minor contributor to this positive overall performance despite having been a highly successful market for many years. Africa and the Middle East performed strongly, with growth of 13.3 percent.

Worldwide network

Endress+Hauser invested 349.3 million euros – more than in any other year in its history – in new buildings, equipment and IT. The Group commissioned new production facilities at its campus in Chhatrapati Sambhajinagar (formerly Aurangabad), India, dedicated a guest house in Arlesheim, Switzerland, and opened regional logistics hubs in China and India. The company is currently implementing investment projects valued at over 550 million euros, the biggest of which is in Maulburg, Germany.

Sustainable performance

Despite making large capital investments and creating additional jobs, the Group maintained profits at high levels, recording net income of 407.9 million euros, only 0.2 percent down from the prior year. This corresponds to a 14.1 percent return on sales. “Commercial success is the foundation that allows us to further drive our company’s sustainability,” Dr Selders emphasized.

In the annual EcoVadis sustainability benchmark, Endress+Hauser scored 78 out of 100 points, its highest rating ever. The Group has thus retained its Gold status, a placing that puts it among the top 5 percent of the 130,000 or so rated companies.

New fields of application and future markets

A strategic partnership with sensor manufacturer SICK in process automation expands the offering in gas analysis and gas flow measurement technology. Endress+Hauser strives to support its customers even better in increasing the efficiency of their plants, protecting the environment and reducing their carbon footprint. “Endress+Hauser is broadening its market base. We are covering new fields of application and tapping into future markets,” said Supervisory Board president Matthias Altendorf. About 800 sales and service employees have transferred from SICK to Endress+Hauser under the partnership. Production and further development of gas analysis and measurement devices has been bundled under the umbrella of Endress+Hauser SICK GmbH+Co. KG, a 50/50 joint venture between the two companies that has around 730 employees across five locations in Germany.

AI, Robotics, and the Future of Smart Manufacturing

Qt Group, the global software company who offers a variety of solutions from development of mobile and desktop applications to quality assurance tools hosts a webinar series called the “Visionary Voices of Tech”

In the current webinar episode “AI, Robotics, and the Future of Smart Manufacturing” Michele Rossi, Industrial Automation Industry Director of Qt Group discussed with experts the changing landscape and trends taking place in the industry at the moment. Guests were Daniele Bernardini, CEO of Cognivix, Przemysław Krzywania, HMI Director at Spyrosoft, Kai Hackbarth, Bosch Global Digital Solutions’ Head of Product and Solutions and Tommi Mänttäri, Senior Manager R&D of the Qt Group.

As industrial automation accelerates, manufacturers face the dual challenge of innovation and security. The experts explore how AI, robotics, and smart technologies are transforming manufacturing—while emphasizing the importance of building secure, resilient systems from the start.

In the webinar viewers can learn about AI-powered robotics and edge computing reshaping smart manufacturing, the role of multimodal human-machine interfaces (HMIs) in safer, more intuitive collaboration and the impact of evolving regulations like the AI Act and the Cyber Resilience Act on industrial solutions.

Gain expert insights on the significance of embodied AI and the challenges of integrating physical AI into real-world environments, stressing the importance of secure programming standards and industry standardization.

A recording of the webinar is available on the Qt website: https://www.qt.io/live-webinars-and-events, together with overview and registration page for all events and webinars.

AI for Advanced Materials Design Wins Inaugural £1 Million Manchester Prize

Polaron’s AI model explores thousands of material designs for next-generation batteries in under a day - a task that takes current state-of-the-art simulations around 50 years. This achievement wins the annual multi-million-pound Manchester Prize from the Department for Science, Innovation and Technology in the United Kingdom.

Advanced materials underpin every facet of modern life - from metal alloys that support infrastructure to lithium-ion batteries powering electric vehicles. Despite their importance, traditional methods for designing these materials are slow, costly, and inefficient due to complex manufacturing processes.

Polaron is the first-ever winner of the Manchester Prize. Launched in 2023, the first year of the Manchester Prize called upon the innovators, academics, entrepreneurs, and disruptors in the UK to enter AI solutions that would deliver public good, receiving nearly 300 entries.

Polaron has developed state-of-the-art generative AI that leverages microstructural image data - showing the features of a material only visible under a microscope - to bridge the gap between the way materials are made and their performance. The technology empowers engineers to characterise materials, quantify microstructural variation, and optimise microstructural designs faster than ever before. Polaron has published scientific papers that demonstrate a more than 10% improvement in energy density of batteries is possible, roughly equivalent to adding 20 extra miles of range to a typical electric vehicle.

Polaron was founded by Dr Isaac Squires, Dr Steve Kench and Dr Sam Cooper, spinning out their research at Imperial College London in November 2023. The growing start-up unites AI, engineering, and materials science, paving the way for material innovations in batteries and beyond.

Its AI models can explore thousands of material designs in under a day - a task that would take current state-of-the-art physics-based simulations around 50 years.

What the Polaron model can explore in a matter of seconds, takes simulations 12-48 hours. Therefore, exploring 20,000 variations would take Polaron’s models around 1 day, and simulations around 50 years. SOURCE: Kench S et al (4 December 2024), Li-ion battery design through microstructural optimization using generative AI, Matter, Volume 7, Issue 12, pp. 4260-4269. Available at https://www.sciencedirect.com/science/article/pii/S2590238524004466

Dr Isaac Squires, CEO of Polaron, winner of the first Manchester Prize, said: “We are thrilled to have won the first ever Manchester Prize - it has been an extraordinary team effort. In the last year, we have turned the research we pursued at Imperial College London into a commercial product, using our AI to reduce years of materials development into a matter of days. We are now working with our first customers in the battery manufacturing sector to apply Polaron to improve the performance of EVs by extending range and reducing charge times. While this has been our core market to date, Polaron is material agnostic, and we are already bringing our rapid design capabilities to industrial manufacturing more widely, including alloys, composites and catalysts.”

About the first Manchester Prize

The Manchester Prize is a multi-million-pound, multi-year challenge prize from the UK’s Department for Science, Innovation and Technology to reward UK-led breakthroughs in artificial intelligence for public good. It is rewarding innovations that will help to transform the lives of the people across the UK and continue to secure the UK’s place as a global leader in cutting edge innovation. In its first year, the Manchester Prize sought innovations from UK-led teams that overcome challenges in the fields of energy, environment and infrastructure.

Feryal Clark, Minister for AI said: “The Manchester Prize shows how we’re putting AI to work for people all over the country – supporting breakthroughs and innovations which will unlock so much positive change in our lives.”

Nick Jennings, chair of the judging panel for the Manchester Prize and Vice-Chancellor of Loughborough University, added: “Choosing a winner of the inaugural Manchester Prize was an incredibly tough decision. Polaron stood out because of its highly innovative approach to revolutionising a process that will unlock a multitude of possibilities for industry. Advanced materials play an extraordinarily important role across our lives; Polaron’s capacity to transform the pace of materials research and development is truly exciting and is a great example of AI being used for social good.”

Canton Fair – An Event with Global Reach

The opportunity to attend the 137th session of the China Import and Export Fair is a new and interesting experience for me. It is new after nearly twenty years of attending European B-2-B events.

Having attended European shows in the broader factory automation environment since I joined a B-2-B publishing company in the summer of 2006, this week has opened a new chapter in my career. I travelled to Guangzhou, China to attend the 137th Canton Fair as editor of IEN Europe. With its 55 exhibition sections and 172 product zones, this is the most horizontal event I have attended in my professional life; even the Hannover Messe, one of Europe's major spring events each year, has a fairly vertical selection of industries compared to this. Certainly one of the first things you notice is the high level of internationalisation, with buyers from more than 210 countries and regions.

China's industrial innovations in batteries, photovoltaics, digital technologies and intelligent manufacturing are represented with a focus on advanced technologies and green solutions.

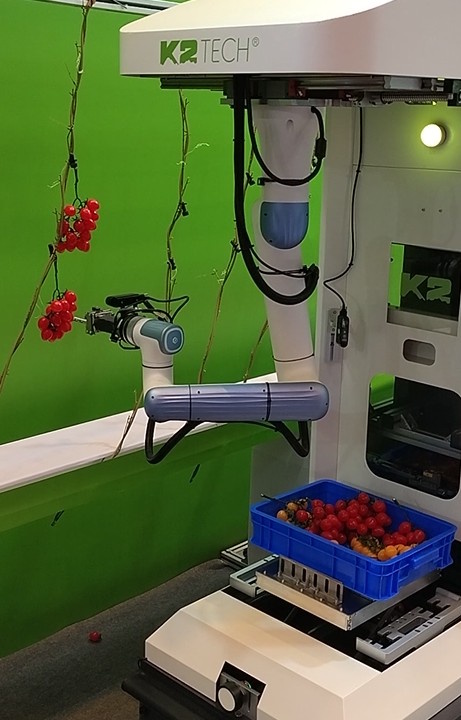

One of the new highlights of the show is the Service Robots Zone, which showcases the latest developments and innovations. From manufacturers of joints and grippers that work like a human hand, to cobots and mobile robot units for the agricultural industry, harvesting fruit or vegetables such as tomatoes, they are all there. And that is not all. You can also find innovative designs for surveillance and detection, used for monitoring tasks in hazardous industrial areas, or for finding and rescuing people in a fire zone or after a natural disaster.

Another trend you can see, as at the European events, is that robots are becoming humanoid. When it comes to service and human-machine interaction, these design features clearly make sense, as they allow people to interact with a friendlier-looking machine. The benefits in industrial and manufacturing environments remain to be proven. However, a few years ago, nobody would have thought that a 20-inch multi-touch interface would be the way to go for machine operation, and you know what customers are demanding in terms of HMIs today.

With the growing investment in China's robotics sector over the next 10 years, the size and versatility of the Service Robot Zone at the show will certainly grow to the next level. I really hope to come back in the coming years to see this transformation and innovative ideas live and in action.

Altair Names MAIT Group as Channel Partner

MAIT will offer the entire Altair simulation and data analytics portfolio to all customers in Germany, Austria, Belgium, Luxembourg, Netherlands, Switzerland and Liechtenstein

Altair welcomes MAIT Group as a new channel partner. Within the partnership, MAIT will offer Altair’s leading simulation solutions throughout the DACH, BENELUX and Liechtenstein Regions.

"MAIT offers solutions that span the entire product lifecycle, from development to manufacturing right through to services. With this comprehensive portfolio, they are an excellent addition to the Altair partner ecosystem,” said Kimon Afsaridis, vice president of indirect sales EMEA and managing director – Eastern Europe, Altair. “Focused on the machinery, aerospace, and healthcare industries, MAIT delivers innovative digital solutions to their customers. In addition to their complementary offerings, they share a similar company culture to ours, driven by passionate people and a deep expertise in the industries they serve. With this partnership all signs point to growth in the DACH region, where together we will provide customers with full support and high-value products tailored to their needs.”

Software for critical business areas

"This agreement with Altair significantly broadens our simulation portfolio," said Stefan Niehusmann, CEO, MAIT-Group. "We remain dedicated to providing cutting-edge solutions to our customers across the industries we serve. With Altair's offerings, our customers now have access to a comprehensive range of capabilities - from structural simulation and electromagnetics to data analytics. They can benefit from faster decision-making, AI-powered simulation tools, and accelerated time-to-market for their products."

MAIT Group provides innovative digital solutions in product lifecycle management, enterprise resource planning and Cloud- and managed services. With its three business divisions, ERP, PLM and IT, MAIT is a holistic and long-term solution provider in all its over 7000 customers' critical business areas. MAIT (a neologism made up of "mate" for partner, "IT" and "AI" for artificial intelligence) generates sales of ~ €200 million and implements, with its 900 employees, specific solutions in close cooperation with their customers at more than 25 locations in Germany, Austria, Switzerland and Benelux.

ABB Plans to Spin off Its Robotics Division

Plan for a listing as separate company in the second quarter of 2026

ABB announced a process to propose to its Annual General Meeting 2026 to decide on a 100 percent spin-off of its Robotics division. The intention is for the business to start trading as a separately listed company during the second quarter of 2026.

Peter Voser, Chairman of ABB, said: “The board believes listing ABB Robotics as a separate company will optimize both companies’ ability to create customer value, grow and attract talent. Both companies will benefit from a more focused governance and capital allocation. ABB will continue to focus on its long-term strategy, building on its leading positions in electrification and automation.”

ABB Robotics provides intelligent automation solutions to its global customer base. Customer value is created through the differentiated offering of the broadest robotics platforms, including Autonomous Mobile Robots, software and AI combined with proven domain expertise to a broad range of traditional and new industry segments. More than 80 percent of the offering is software/AI enabled.

Morten Wierod, CEO of ABB, added: “ABB Robotics is a leader in its industry and there are limited business and technology synergies between the ABB Robotics business and the remainder of ABB divisions, with different demand and market characteristics. We believe this change will support value creation in both the ABB Group and in the separately listed pure play robotics business.”

The ABB Robotics division has approximately 7,000 employees. With 2024 revenues of $2.3 billion it represented about 7 percent of ABB Group revenues and had an Operational EBITA margin of 12.1 percent.

If shareholders decide in favor of the proposal, the spin-off is planned to be done through a share distribution, whereby ABB Ltd.’s shareholders will receive shares in the company to be listed (working name “ABB Robotics”) as a dividend in-kind in proportion to their existing shareholding.

Dr.-Ing. Gunther Kegel and Werner Guthier Pass the Baton to Their Successors at Pepperl+Fuchs

After three decades of continuity at the top of the company, Pepperl+Fuchs is now repositioning itself: Dr.-Ing. Gunther Kegel, CEO for many years, and Werner Guthier, CFO, are stepping down from the Executive Board as planned.

Both will initially remain with the family shareholders of Pepperl+Fuchs in an advisory capacity. They will be succeeded by Dr. Wilhelm Nehring as the new CEO and Martin Walter as the new CFO – a deliberate and long-planned rejuvenation to actively shape the future of the company. Both will take up their duties on May 1, 2025.

Dr. Wilhelm Nehring most recently served as CEO of a mechanical engineering company, and previously held senior leadership positions in the electrical industry. Martin Walter was formerly Senior Vice President of Controlling & Accounting at a globally active German industrial company. Both have built impressive careers and bring fresh perspectives and new impulses to Pepperl+Fuchs' leadership, which the Mannheim-based company seeks to leverage for its continued success. The entire executive board is convinced that the expertise, strategic mindset, and innovative approaches of Dr. Wilhelm Nehring and Martin Walter will enrich Pepperl+Fuchs with fresh ideas and a modern leadership culture, bridging the significant gap left by Dr.-Ing. Gunther Kegel and Werner Guthier.

"After more than 30 years of responsibility for this company, it is naturally not easy to let go of the reins. One does not want to leave the role without knowing that a successor will continue the task with just as much passion. However, I am absolutely confident in Dr. Wilhelm Nehring and Martin Walter: they have great potential and also possess the spirit and vision needed to lead Pepperl+Fuchs into a successful future. They will do a fantastic job!" said Dr.-Ing. Gunther Kegel. Together with the family shareholders and CHRO Florian Ochs, he has carefully prepared this transition over an extended period to ensure the company’s continuity and stability.

With this generational change, Pepperl+Fuchs is sending a clear signal for the future: The new executive leadership will continue the company’s successful trajectory while also exploring innovative paths to ensure long-term growth

Certified Components: A Strategic Advantage in Cybersecurity

Certified Security at the Core: How IEC 62443-4-2 Devices Help Machine Builders Boost Efficiency and Compliance

Automation

In the face of growing cybersecurity threats and tightening regulations such as the EU Cyber Resilience Act (CRA), machine builders must rethink the role of industrial network devices. Cybersecurity is no longer just a feature. It is a prerequisite for market access, operational continuity, and brand reputation. IEC 62443-4-2 certified devices are emerging as key enablers in this new landscape. They not only support compliance with evolving regulatory frameworks but also simplify certification efforts, reduce integration risks, and promote long-term efficiency.

This article explores how IEC 62443-4-2 certified components contribute to hardening machines, support CE/UKCA certification processes (i.e., CE marking for the European market and UKCA marking for Great Britain, which confirm that products meet safety and performance standards), and offer a futureproof path to CRA compliance.

IEC 62443-4-2: A practical path to hardening machines

IEC 62443-4-2 defines cybersecurity requirements for individual components such as routers, switches, protocol converters, access points, industrial computers, and more. Certified devices meeting Security Level 2 (SL2) provide robust protection against intentional misuse by attackers possessing moderate resources and skills. This level aligns well with the threat models most machine builders face in real-world industrial settings.

For machine builders aligning their systems with IEC 62443-3-3, which focuses on system-level security requirements, integrating certified components becomes a strategic shortcut. Each IEC 62443-4-2 certified component brings predefined capabilities that fulfil key system-level requirements, simplifying the builder's path to compliance.

Using certified components means a machine is built on a known, tested, and independently verified security foundation. Each certified device brings capabilities like authentication, access control, secure boot, signed firmware, encrypted communication, and more. The advantage extends beyond the product. It hardens the machine itself, streamlines audits, and supports third-party system certification efforts.

Even when using non-certified versions, the benefits are tangible. All Moxa products are developed under an IEC 62443-4-1 certified process, meaning the elevated security baseline applies across the entire portfolio. Certified components uplift the overall ecosystem by enforcing better design practices, consistent patching routines, and structured response protocols.

Going beyond compliance: Built-in features that deliver real value

IEC 62443-4-2 compliance transcends mere labelling; it embodies a design philosophy that prioritizes security. Key features include:

- Routers and Wireless Access Points: Equipped with embedded firewalls and integrated IDS/IPS with Deep Packet Inspection (DPI) to detect anomalies in industrial protocols.

- NAT Functionality: Supports network segmentation and conceals internal IP structures, reducing the attack surface.

- Serial Device Servers: Provide encrypted communication for legacy equipment, improving protocol security without requiring complete infrastructure upgrades.

- Protocol Converters: Not only bridge old and new systems securely but also protect against protocol abuse by verifying and controlling data exchanges between differing standards.

- Managed Switches: Enable granular traffic control, logging, and access policies features that unmanaged switches lack but are increasingly necessary for compliance and audit readiness.

A good example is the use of IEC 62443-4-2 SL2 certified ARM-based industrial computers, which provide a secure foundation for software integration. Such platforms help customers align with security-by-design principles. Moreover, policies such as "update without upgrade" ensure that the certification status remains intact over time, avoiding unexpected revalidation work.

To illustrate the practical benefits of certified components, consider the following scenarios.

In a typical automotive manufacturing environment, integrating Moxa’s IEC 62443-4-2 SL2 certified industrial secure routers, such as the EDR-G9010 and TN-4900 Series, can help strengthen cybersecurity across automated assembly lines. These devices offer strong protection against cyber threats while supporting CE and UKCA certification processes. By using certified components from the outset, manufacturers can reduce integration risks and improve operational efficiency, all while aligning with regulatory requirements.

Similarly, in a representative industrial automation setup, deploying IEC 62443-4-2 certified Ethernet switches, like Moxa’s EDS-4000/G4000 Series, enable better network visibility, traffic control, and access policy enforcement. These capabilities are increasingly important for meeting the technical and documentation standards required by the Cyber Resilience Act and other industry regulations.

Machine builders using unmanaged switches should migrate to managed and certified options for enhanced security. Greater visibility, policy enforcement, and traceability help meet CRA and other regulatory requirements that demand documentation and incident response capability. Machine builders using unmanaged switches should migrate to managed and certified options for enhanced security. Greater visibility, policy enforcement, and traceability help meet CRA and other regulatory requirements that demand documentation and incident response capability.

Security built into the organization: Long-term CRA readiness

IEC 62443-4-1 certification ensures the implementation of secure development processes. This is particularly important for CRA compliance, which mandates long-term support, vulnerability management, and transparency.

In the context of the CRA, machine builders must also ensure the security of their supply chains. This elevates the importance of choosing suppliers who are IEC 62443-4-1 certified ensuring that components are developed, maintained, and supported under a mature security framework.

Key benefits include:

- Structured patching and vulnerability management procedures.

- An active Product Security Incident Response Team (PSIRT).

- Availability of Software Bills of Materials (SBOMs), which allow machine builders to identify and track known vulnerabilities in third-party components is critical for risk assessment and compliance.

- Supplier transparency and traceability throughout the product lifecycle, as required by the CRA.

Looking ahead: Certification as a business enabler

IEC 62443-4-2 certification isn't just for component manufacturers. Machine builders can also seek certification for their own systems. By starting with already-certified components, the overall scope of testing and documentation can be reduced significantly. More importantly, CRA enforcement is expected to be strict. Compliance may soon determine who can sell in the European market and who cannot.

Certification transcends risk avoidance, serving as a significant market advantage. Choosing suppliers and technologies that are already compliant simplifies the journey and reduces long-term operational costs.

Conclusion: Building compliance and resilience from the ground up

Certified security components streamline machine certification, bolster operational resilience, and equip organizations to meet evolving cybersecurity regulations. Adopting IEC 62443-4-2 certified devices, whether switches, routers, protocol gateways, or industrial PCs, support a structured, audit-ready approach to cybersecurity. Vendors that also follow certified development lifecycles and maintain a robust PSIRT offer the added benefit of post-sale transparency and support, both of which are key tenets of the Cyber Resilience Act.

Moxa, for example, offers the largest IEC 62443-4-2 SL2 certified portfolio on the market, which includes routers, switches, serial servers, protocol converters, access points, and computers. All products are developed under an IEC 62443-4-1 certified process, ensuring consistent secure development practices. Moxa’s Product Security Incident Response Team (PSIRT) is especially mature, and as a CVE Numbering Authority (CNA), the company plays a recognized role in the global cybersecurity ecosystem. This makes Moxa an ideal partner for machine builders aiming to build secure, certifiable, and futureproof industrial systems.

Virtual Model for Safety Planning for Production Environments

Projected Image, specialists in projected safety signage, have launched an innovative virtual warehouse model to help companies visualise their safety planning.

Industrial Equipment & Supplies

Newcastle-based Projected Image provide LED projectors that cast bright, hard-to-ignore health and safety signs onto any surface.

To help even more businesses simplify their health and safety signage, Projected Image have launched a cutting-edge tool which enables users to view projected signage solutions in a fully immersive virtual 3D environment.

“Safety is paramount in so many industries, but actually visualising how projected safety signage integrates into an existing workspace can be a challenge without an on-site demo. Our new interactive model gives companies the ability to virtually plan, test and perfect their signage before implementing it in real life, saving both time and resources" says Ian Spoors, Managing Director of Projected Image.

Demonstrating different conditions

Designed to disrupt outdated industry norms, the model is a browser-native experience which uses modern web rendering technologies to deliver projected safety signage in an interactive, 3D environment, requiring no plugins and no downloads for instant access. Built and optimised with performance-first principles, users can seamlessly navigate, pan and zoom through a warehouse simulation, exploring Projected Image’s signage solutions under dynamic conditions.

The model can also demonstrate how signage will look under various lighting conditions and in relation to obstacles and hazards that can be present in real life scenarios. The projected signage experts also say that the model is easy to use – with an interactive interface suitable for all technical proficiencies. Users can toggle between different signage systems, designs and lighting effects to address specific safety challenges and understand how the products work in action.

Muting Modules for Enhance Safety and Productivity

Providing safe material flow in the field, the new DMM4 muting module from SICK Sensor Intelligence provides safe human-material differentiation to improve protection and productivity in industrial settings.

Automation, Sensor Technology

As part of its commitment to industrial safety and access guarding, SICK has unveiled its powerful new DMM4 muting module. The DMM4 meets a wide range of muting needs and is highly reliable, flexible and configurable to deliver enhanced industrial safety without compromising productivity.

The DMM4 extension module represents the latest evolution in SICK’s safety solutions. It makes sure operators stay protected from hazardous machinery while materials, boxes and finished products move through smoothly. A robust, in-the-field solution with a host of new features and benefits, the DMM4 is fully compatible with SICK’s deTec safety light curtains and deTem safety light-beam sensors for seamless protection and efficiency with easy installation.

Enhanced safety and efficient material flow

Muting is a method that has been around a long time and has developed to become more versatile. Modern manufacturing requires safe passage of goods between production processes and this is increasingly important as production becomes more complex. A standalone muting module offers high flexibility and safety for free-flowing production and the DMM4 has a small footprint.

The robust muting module is designed to perform in the field and can be easily integrated. It doesn’t require a separate cabinet as it is equipped with protection against dust and water in the field, reducing wiring and commissioning time. A dedicated muting module with a high IP rating, it can be used in safety function up to PLe (ISO 13849)/SIL3 (IEC 62061) and fully supports compliance with ISO 13855, the standard covering the requirements of positioning safeguards with respect to the approach of the human body. The DMM4 is a more powerful, slimmer extension module than previous versions and SICK has released robust new support columns with micro adjustment capabilities and a built-in spirit level to complement it.

Applications for the DMM4 muting module range from logistics (e.g. muting for AGVs, electric forklifts or AMRs), to manufacturing (from large automotive parts to small consumer goods, food & beverage, and pharma).

Martin Kidman, SICK Manager – Safety (S&W Europe), says: “Highly flexible and configurable, the SICK DMM4 is out of the box certified and Plug and Play, with easy installation and connectivity with the SICK deTec safety light curtain. It’s part of a complete range of SICK safety light curtain products, including light curtains, sensors, fittings and muting modules.

Software Solution for AI-Monitoring and Notification

Instant detection and response to critical events from multiple data sources

Automation

DataTalk, the versatile no-code platform focused on operational and manufacturing efficiency is pleased to announce the launch of its latest product, AI Alarm & Notify, designed for intelligent real-time monitoring and notification. This solution seamlessly integrates with existing devices and instantly alerts users to any discrepancies through multiple communication channels such as email, WhatsApp, Discord or Slack.

Designed to enhance operational efficiency and safety, this advanced AI-powered notification platform leverages artificial intelligence to provide end users with a sophisticated AI assistant. This AI system provides real-time insights, reduces alarm fatigue, and supports industrial operators in analyzing situations, predicting potential issues, and making proactive, well-informed decisions that enhance efficiency and reliability.

Data processing from multiple sources

The system can process data from PLCs, IIoT sensors, MQTT, databases, and other sources, enabling comprehensive monitoring of technological processes. The graphical no-code computing module allows users to combine and transform data without the need for programming, simplifying system configuration and management. The system allows for the setup of hierarchies and custom filters, ensuring information to reach the right people at the right time. With the AI Bot Talkie feature, users can directly interact with their system, gaining instant insights and solutions—equivalent to expert supervision 24/7. The more information the AI Bot gets, the more helpful it is. AI Alarm & Notify is fully compatible with SCADA and MES systems, allowing for seamless integration into existing infrastructures.

As Geopolitical Tensions Rise AI Is Amplifying the Threat of Global Cyberwarfare

Armis, the cyber exposure management & security company, is warning that AI-powered cyberwarfare attacks are now becoming a supercharged cyber weapon and urges organizations to immediately close the divide between current cybersecurity programs and future proactive preparation as threats will increase.

New data from Armis Labs’ third annual global Cyberwarfare report, Warfare Without Borders: AI’s Role in The New Age of Cyberwarfare, shows the threat of AI has increased for organizations and governments worldwide in the past year. Nearly three-quarters (73%) of IT decision-makers globally express concern about nation-state actors using AI to develop more sophisticated and targeted cyberattacks.

“AI is enabling nation-state actors to stealthily evolve their tactics to commit acts of cyberwarfare at any given moment,” said Nadir Izrael, CTO and Co-Founder of Armis. “At the same time, threats are emerging at overwhelming rates from smaller nations and non-state actors leveraging AI to elevate to near-peer cyber threats. It is imperative that cybersecurity leaders shift their programs left of boom, enabling them to stop cyberattacks capable of crippling their operations before there’s any impact to their organization.” 81% of IT leaders say moving to a proactive cybersecurity posture is a top goal for their organization in the year ahead but nearly 3 in 5 (58%) organizations admit that they currently only respond to threats as they occur, or after the damage has already been done.

Staying ahead of threats

Market consolidation, complex regulatory landscapes and gaps in legacy security tool stacks have challenged organizations’ abilities to stay ahead of threats. While many wish to implement AI-driven cybersecurity tools in a proactive defense move, half of IT decisionmakers surveyed acknowledge their teams lack the necessary expertise to implement and manage the technology.

“Current industry dynamics create an appealing environment for malicious actors to intensify their efforts through automated AI offensive driven technologies,” said Michael Freeman, Head of Threat Intelligence at Armis. “Organizations that leverage proven AI security solutions will realize a greater impact in their ability to equip their teams with the resources and time they need to anticipate the tactics that could be used against them and harden their environments in response. Embracing a more proactive approach to threats has never been more important, and closing that divide between intention and ample preparation is within reach thanks to significant advancements in cyber exposure management.”

The 2025 Armis Cyberwarfare Report is based on a study of over 1,800 global IT decisionmakers and proprietary data from Armis Labs. Read the full report from Armis, including a comprehensive breakdown of the findings for each region of respondents and IT decisionmakers from different verticals here: https://www.armis.com/cyberwarfare-2024/

Hybrid Safety Module for EtherNet/IP

One module for discrete I/O, safety I/O, and IO-Link

Automation

Murrelektronik simplifies industrial automation with smart, seamless and cost-effective solutions. The MVK fusion fieldbus modules are a good example of this. These hybrid modules unite three elementary functions of installation technology: discrete I/O, safety I/O, and IO-Link. The combination of standard and safety communication into one device streamlines system architecture and makes installation significantly easier and faster. This approach means that machine builders and system integrators need fewer fieldbus modules per modular unit, ideally only one – which greatly reduces installation effort and saves valuable space.

3-in-1 module

Murrelektronik adds a new member to the MVK Fusion family: MVK Fusion CIP Safety. As the name suggests, it utilizes the "Common Industrial Protocol Safety" – or CIP Safety for short. This means that machine builders and system integrators can now also use this popular 3-in-1 approach and its many advantages for EtherNet/IP applications. CIP Safety is a certified extension of the widely used CIP protocol (IEC 61508) that enables the safe transmission of data in real time – without the need for separate safety networks. The new device supports this functionality, helping engineers easily integrate safety into both new and existing Ethernet/IP systems.

The device features robust M12 L-coded power connectors, making it ideal for space-constrained installations. In addition to their compact form factor, these connectors offer high current capacity, reliability and proven coding.

Simplified configuration

The new hybrid safety modules for EtherNet/IP also simplify the configuration of safety-related sensors and actuators. Configuration is handled directly through the controller's engineering software. This means that no external tools are needed to transfer the Safety Network Number (SNN) or device settings, minimizing setup time and reducing errors. The safety output on Port X3 provides unmatched flexibility. It can be configured as two sourcing outputs, one bipolar output, or a combination of both.

Each port offers channel-specific customization to suit a variety of application needs, improving overall system flexibility and performance.

The new MVK Fusion CIP Safety modules are designed in detail for installation close to the process and use in harsh environments: They are IP67-rated and feature a robust, fully encapsulated metal housing, making them resistant to shock, vibration and temperatures from -22°F to +140°F (-30°C to +60°C). The device continuously monitors each channel for conditions such as overload, short circuits, and cable breaks. This proactive approach allows for faster fault detection and resolution, minimizing unplanned downtime.

Solenoid Interlock with New Accessories

Compact and cost-effective safety solution for versatile applications

Automation

The slim-line solenoid interlock AZM150 from Schmersal now offers an even wider range of applications thanks to new accessories and, as a complete system, it is also a very cost-effective safety solution. One new accessory is the rear-mounted push button, which can be used for emergency release or emergency unlocking. Emergency release makes it possible to leave the area of danger from the inside if a guard door has been closed inadvertently. Emergency unlocking enables the guard door to be opened from the outside. The push button is available in two different versions: the 45 mm version for use with door pillar thicknesses of 40 mm, for example, where the MP-AZM150-1 mounting plate can be used for mounting, and the 170 mm version for use with door pillar thicknesses up to 170 mm.

Another new accessory for the AZM150 is the Bowden cable release with an overall length of 6 metres, which enables remote unlocking in an inaccessible interlock installation situation. This provides a safeguard in particular hazardous situations. Should an operator inadvertently become locked inside a system, a Bowden cable can be used as an emergency release. When working outside the danger zone, the Bowden cable serves as an emergency release.

Rotating actuator head

An advantage of the AZM150 interlock is the rotating actuator head, which is locked by simply putting the cover in place instead of a screw connection. The 360°-rotating actuator head, with its two actuator entrances, enables different mounting positions and approach options. This feature also decisively contributes to the versatility of the AZM150, which boasts a holding force (FZh) of 1,500 N.

Electromechanical switch with high coding

The AZM150 is an electromechanical solenoid interlock with a "high" coding level and therefore offers excellent protection against tampering. The advantage for the user: with high coding, fewer additional measures against tampering are required in accordance with ISO 14119, such as mounting out of reach or in a concealed position.

With the new accessories, the series is now a complete system that covers a wide range of applications up to PL d / Cat3 and is also a very cost-effective solution. The AZM150 series is ideal for smaller machines and systems or for cost-sensitive applications where a low performance level is required. At the same time, the compact electromechanical solenoid interlock precisely fulfils the required safety level at a moderate price.

MES Is Not Rocket Science if You Treat It Right

At the HANNOVER Fair 2025 IEN EUROPE editor Kay Petermann met with Francisco Almada Lobo, CEO of Critical Manufacturing to talk about the benefits of a Manufacturing Execution System (MES) and why it is helpful for companies of all sizes to have one.

Automation, Expo Channel: Hannover Messe

IEN Europe: How would you describe the main benefits of an MES?

Francisco Almada Lobo: Let’s clear one thing up first—MES isn’t software. It’s a concept, a capability, a set of functions manufacturers use to execute production and operations. Every manufacturer does MES already... whether it's with Excel, clipboards, or homegrown apps duct-taped together. The difference is how well you're doing it.

Now, modern MES software is what digitizes and automates these core execution functions—like scheduling, work instructions, traceability, WIP tracking, and quality management. And when done right? The benefits are massive:

- Visibility: Real-time insight into what’s happening on your shop floor.

- Traceability: From raw materials to finished goods—every step tracked.

- Productivity: Less time spent on admin, more time making product.

- Quality: Built-in checks and validations reduce defects.

- Compliance: Audit trails and e-signatures made easy.

- Agility: Faster changeovers, adaptive scheduling, and smarter responses to issues.

In short, MES turns tribal knowledge into digital workflows. It gives frontline workers superpowers, managers clarity, and executives confidence. And it sets the foundation for bigger moves like AI, digital twins, and lights-out manufacturing.

IEN Europe: Why does every company, even small ones, need a MES in the process of industrial transformation?

Francisco Almada Lobo: “Need” is a relative term. Technically, no manufacturer needs an MES the same way a fish doesn’t need water filters to survive… but try thriving without it in today's digital ecosystem.

Let’s start with the basics: the core capability of a manufacturer is to manufacture. That means execution isn’t just important—it’s the core function. Everything else—planning, procurement, quality, supply chain, even finance—exists to support and enable that core: getting the right thing made, the right way, at the right time.

And if you’re trying to digitally transform your business, if you want to plug in all the cool tech like AI, predictive analytics, autonomous scheduling, or even digital twins—guess what they all rely on?

Solid execution data. And that means doing MES right—not just checking a box that says you have one.

MES isn’t just another system. It’s the digital foundation for everything that touches production. If your execution is a mess—running on clipboards, spreadsheets, or duct-taped workarounds—then all those shiny technologies won’t help. They’ll just amplify the chaos.

Small manufacturers often think they can wait. But that’s like waiting to build a foundation after the house is up. MES done right gives you the structure, visibility, and control to build something scalable, resilient, and ready for the future. It’s not about getting MES.

It’s about getting MES right.

IEN Europe: How complex is the process of integration?

Francisco Almada Lobo: It can be complex—but it doesn’t have to be. The trick is to treat MES like a program, not a project.

Yes, you’ll need to connect MES to machines, ERP, quality systems, maybe even warehouse and lab systems. But you don’t have to do it all at once. Start with a focused scope, deliver quick wins, and build momentum.

Integration complexity depends on:

- Your existing systems and how modern (or ancient) they are.

- How much standardization exists across your sites.

- How clean and structured your data is.

- Whether you’ve picked a flexible MES platform or a rigid one.

Smart manufacturers don't try to eat the elephant. They carve out logical phases. Get one line, one process, or one plant running well—and replicate. Bonus points if your MES supports out-of-the-box connectors, REST APIs, or OPC UA—it makes the plumbing much easier.

Bottom line? MES integration isn’t rocket science. But it’s not plug-and-play either. You need strong leadership, realistic timelines, and an MES partner who’s done this before.

Get those right, and integration goes from scary to scalable.

IEN Europe: Thanks for your time and insights!

PLC Technology with Advanced Chatbot Functionality

Enhanced engineering and runtime performance with fully embedded chatbot function

Automation

Beckhoff announced the new TwinCAT PLC++ software. Both engineering and runtime are noticeably faster, without compromising on TwinCAT’s signature strengths of seamless integration, compatibility, and openness. Leveraging state-of-the-art compiler technology and a new system structure, the advanced chatbot function TwinCAT CoAgent is now fully embedded as an efficient programming assistant.

In TwinCAT PLC++ runtime, the same control code runs up to 1.5 times faster compared to the previous TwinCAT PLC version. A major highlight is the new TwinCAT PLC++ compiler, which further optimizes control code execution time, delivering an overall performance boost of up to 3 times. The new TwinCAT PLC++ architecture also supports even deeper integration of TwinCAT functions. This allows TwinCAT CoAgent, the evolution of TwinCAT Chat, to be efficiently integrated as a programming assistant that supports both textual and graphical code generation.

Creating I/O topologies via chat

TwinCAT CoAgent takes control engineering to the next level by seamlessly integrating cutting-edge technology directly into TwinCAT projects. The agent provides effective support for a wide range of tasks, from precise code suggestions and smart code optimization to automatic creation of comprehensive documentation. The content generated by TwinCAT CoAgent can be easily incorporated into established engineering projects once it has been checked by a user. TwinCAT CoAgent also provides direct access to Beckhoff’s comprehensive documentation and supports the development of user-friendly HMI controls. This means that user interfaces can be designed and configured faster and more intuitively than ever before. The option is even available to create I/O topologies effortlessly via chat, including renaming terminals and configuring new I/O modules. In the future, it will be possible to adjust parameters individually, while an intelligent assistant will provide support with the optimum configuration. This not only speeds up the I/O configuration, but also makes it particularly flexible for specific requirements. TwinCAT CoAgent’s comprehensive functionality positions it as a personal digital assistant with the potential to revolutionize engineering workflows.

Real-Time Monitoring of Utilities

VPInstruments is proud to announce the release of VPVision 8.1. A major upgrade packed with enhancements that boost performance and improve data accessibility. It offers faster data processing and advanced KPI functions. The release offers real-time monitoring of your factory utilities, like compressed air, power, gas, steam, water and more. Creating customized performance indicators The enhanced...

Energy Efficiency, Industry 4.0

VPInstruments is proud to announce the release of VPVision 8.1. A major upgrade packed with enhancements that boost performance and improve data accessibility. It offers faster data processing and advanced KPI functions. The release offers real-time monitoring of your factory utilities, like compressed air, power, gas, steam, water and more.

Creating customized performance indicators

The enhanced Audit Mode, now available for all subscriptions, VPVision provides high-resolution, second-level data for in-depth analysis of compressed air and gas systems. This allows end users to enable granular data collection, giving their air audit consultant direct access to real-time data for actionable improvement recommendations for system performance. The improved Audit Mode now writes data directly to CSV files in real time. With the new CSV publisher, you gain complete control on data export of this huge amount of data. Options include amongst others, time interval, data averaging, channel selection and data formatting. VPVision 8.1 introduces an 'if' processor element for KPI formulas, expanding the capabilities of virtual channels. This enables advanced calculations such as: Converting compressor amperage into flow output or creating customized performance indicators based on real-time conditions. Users get a complete real-time energy monitoring solution for all utilities within the company to track usage and finding patterns in supply and demand. VPVision helps you to prevent unexpected downtime by sending out early warnings about high temperature, deteriorated dew point, pressure drop, etc. Target for energy savings and improved performance can be reached on individual, team or at company levels.

Scalable Industrial Connector Series

Circular Series with hybrid inserts for a wide applicational range

Electronics & Electricity

Harting offers additions to its circular connector series ICC (Industrial Circular Connectors) in size 20. The application fields range from robotics and automation through to mobile machinery and energy grid infrastructure.

The ICC 20 4/3 ("4Slash3") represents an attractive solution for the supply and control of drives in robotics and automation, for example, handling power up to 40A in combination with signal contacts. The circular connector features the proven Han® C and Han D® contacts. Four power contacts, three signal contacts (up to 10A/250V) and one PE contact are accommodated in the insulator. Another expansion to the series is a single pole, so that users can also transmit significantly higher power for their machines and devices. A single connector transmits up to 400A/600V, making it suitable for energy-intensive applications such as robot arms for heavy load handling or welding robots. Other application areas include mobile machinery and energy network infrastructure scenarios.

Wide range of insulating bodies available

All of the series housings offer a high degree of protection against the ingress of dust and water (IP67/IP69), making them ideal for deployment in harsh industrial environments. The housings reliably shield electromagnetic fields (EMC), thereby ensuring the signal integrity of the system.

The number of potential applications for the ICC 20 design is also multiplied by the integration of insulating bodies, which were previously reserved for the Han® 3A format. A multitude of especially efficient solutions for power, signal and data transmission are possible here – from simple Han® C, Han D® or Han® E monoblocks through to USB, RJ45 and other data interfaces. The size 3 A insulators also provide various connection technologies, such as the new push-in quick connection technology.

60 W DC/DC Converter

Compact converter fully compliant with railway-specific EMC requirements

Electronics & Electricity

Autronic has redefined a true classic with the updated HFBC60-W/Ks. Under the motto "Familiar on the outside, completely new on the inside," the compact and powerful converter has undergone extensive modernization to continue meeting the demanding requirements of railway technology. The HFBC60-W/Ks complies with the stringent standards EN 50155 and EN 50121-3-2, making it ideal for use in harsh environments along the railway too.

The HFBC60-W/Ks’s compact dimensions (113 mm x 46 mm x 35 mm) enable seamless design-in. Its full compliance with railway-specific EMC requirements (surge, burst, emissions, and immunity) eliminates the need for additional circuitry. An integrated 10-ms hold-up time ensures reliable operation even during short-term voltage dips. The converter impresses with features such as active inrush current limitation, active reverse polarity protection, and comprehensive safeguards against overcurrent, overvoltage, and overheating (OVP, OCP, OTP). Customers have long appreciated how easy this converter is to put into operation.

Flexibility and Efficiency

With just one converter, nominal input voltages from 24 V to 110 V (±40%) are covered, significantly simplifying the approval process for customer applications. The galvanically isolated converter guarantees reliable performance with an efficiency of up to 91 % and an output power of 60 W, providing full operating security without derating—even under extreme temperature conditions (OT4, ST1, ST2) or all permissible input voltage ranges.

Installation is remarkably simple: natural convection combined with contact to the mounting surface is entirely sufficient. The materials chosen for the PCB and potting compound meet the highest fire safety standards in accordance with EN 45545-2 (HL3). The HFBC60-W/Ks is available with output voltages of 5 V, 12 V, and 24 V, seamlessly integrating into any design. Versions with a power output of 100 W are also available.

Miniature Solid-State Li-Ion Battery

200C Discharge C-Rate and quick recharge offer opportunities in new applications

Electronics & Electricity

ITEN unveiled a major advancement in energy storage. ITEN’s latest SSB achieves an unprecedented 200C discharge rate (200 times the battery’s capacity per hour) —100 times higher than conventional Li-ion batteries—setting a new benchmark for miniaturized energy storage. This technology is now being manufactured at scale to build the Powency™ product family, with the company’s high-volume production capabilities ready to meet growing demand for IoT and other connected devices across various industries.

With over 100 customers across various industries already sampling ITEN batteries and designing connected devices with ITEN’s technology, the Powency™ products are now qualified for full-scale production in the second half of 2025. ITEN’s Dardilly pilot line has the capacity to produce more than 30 million batteries per year, with ongoing plans to launch a high-capacity manufacturing facility by 2028 to meet increasing market demand.

This technological advancement is based on ITEN's expertise in nanomaterials to engineer full-ceramic electrodes featuring a patented mesoporous structure that significantly enhances their specific surface area. This scalable technology delivers an unmatched combination of power density, recharge speed, safety and reliability. ITEN is currently transforming energy solutions for industries by providing very small, efficient, and long-lasting power sources. This innovation enables new possibilities for a wide range of end markets, reducing dependence on traditional energy storage technologies and offering more sustainable and reliable alternatives.

Unmatched Performance for High-Power IoT Applications and Beyond

ITEN’s Powency™ product family of solid-state batteries is designed for high power density, ideal for delivering rapid energy bursts in wireless sensor applications. The 200C discharge rate is demonstrated by the Powency™ 150 microampere-hours (μAh) model with an 18 mm² footprint, translating into peak current capabilities of 30 milliamps (mA) for 50-millisecond pulse lengths.

All Powency™ batteries will leverage this high-power density attribute to provide the electronics market with area-optimized batteries delivering bursts of current capable of supporting cellular Low Power Wide Area Network (LPWAN) communications.

Conventional Li-ion batteries typically support discharge rates of 2C to 5C, limiting their ability to handle high-power applications. ITEN’s proprietary solid-state battery technology overcomes this constraint, making it an ideal energy buffer when paired with energy harvesters. With their unique power density attribute, these batteries enable instant power delivery, making them particularly suitable for asset tracking, smart homes and buildings, smart agriculture, metering, remote controls, and wireless sensors.

This innovation also enables hybrid architectures where primary batteries are paired with a Powency™ device to improve the cost, lifespan, and sustainability of IoT and other connected devices. Beyond IoT, ITEN is also developing the next generation of SMD solid-state batteries for wearables, consumer and healthcare applications, designed to offer high capacity and energy density for demanding use cases.

Thanks to its solid-state technology, ITEN’s Powency™ batteries retain at least 50% of their capacity at -20°C, whereas conventional Li-ion batteries typically lose 80-90% of their capacity. Additionally, the Powency™ batteries boast a longer cycle life, enduring up to 250 cycles at 100% depth of discharge at 70°C, and recharge quickly - reaching 80% capacity typically in 6 minutes.

ITEN’s full control over the manufacturing process allows the company to create customized battery designs tailored to specific applications.

Enhanced Safety & Higher Sustainability

ITEN’s solid-state battery technology provides enhanced intrinsic safety, eliminating risks of fire, thermal runaway, or ignition. In addition to superior performance, ITEN’s SSBs offer a more sustainable alternative to traditional coin-cell batteries. Their long-lasting, rechargeable design helps reduce battery waste, while the ITEN production process excludes the use of cobalt and heavy solvents. ITEN’s batteries are free of hazardous materials and comply with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), two key European Union environmental regulations focused on chemical safety and environmental protection. The environmentally responsible manufacturing process also operates at low temperatures, minimizing its ecological footprint.

Handheld Thermal Imagers

Multispectral image enhancement offers faster and easier measurements and diagnoses

Test & Measurement, Vision & Identification

FLIR introduces two new thermal spot cameras: the FLIR TG268 and TG298. These thermal imaging cameras provide professionals in the utility, manufacturing, electrical, automotive and industrial sectors with a lightweight, portable and affordable tool for condition monitoring that features a number of key improvements. Among the improvements FLIR has implemented are higher temperature ranges to cover even more applications, improved thermal image resolution and increased data storage capacity. FLIR also introduces on-camera condition monitoring and connectivity to its METERLiNK app for file transfer to mobile devices.

The FLIR TG268 thermal spot temperature camera takes users beyond the limitations of single spot IR thermometers to view and assess hot and cold spots that can indicate potentially dangerous problems. Perfect for the uncompromising demands of commercial electrical, building maintenance and HVAC applications, this innovative thermal imaging camera reduces diagnostic time by providing targeted temperature detection (with a bullseye laser capability), while simplifying repair and maintenance reporting.

Built to withstand harsh operating environments, the FLIR TG268 features an industrial design with IP54 rating, 2-metre drop test, 100-bright flashlight and Type K thermocouple. Its fast start-up time of approximately 6 seconds ensures that it is ready to check everything from electrical connections to mechanical failures quickly and accurately. It measures from -25°C to 400°C (752°F) with a 24:1 spot size ratio and a bullseye laser pointer.

Multi-spectral image enhancement

The imager offers improved detail of native thermal images with Super Resolution (upscaling to best-in-class 320×240). To help diagnose problems faster, it offers FLIR's patented MSX® (Multi-Spectral Dynamic Imaging) image enhancement. With MSX, users can add detail by embossing visual scene details onto full thermal images, providing additional context to accurately target potential faults and troubleshoot repairs.

The FLIR METERLiNK app (with Ignite Sync) can be used to take measurements remotely (from a safe distance) and document inspection data for field reporting and sharing. The app provides a live view of data readings from up to seven paired devices.

For high temperatures

The FLIR TG298 is an industrial thermal diagnostic tool that provides accurate temperature measurement and the ability to image up to 1080°C (1976°F) with a 30:1 spot size ratio and bullseye laser pointer. Applications include temperature measurement and remote monitoring of high temperature applications such as glass furnaces, kilns and forges, as well as manufacturing applications.

Pressure Sensor Module for Direct Connection

Variants with female connector strip, screw terminals or DIL pin connector strips available

Sensor Technology

For pressure measurement in devices with integrated SPS/PLC or other modular control, traditional encapsulated transmitters are often too expensive and too large. OEM sensors for soldering are in-expensive, but in addition to their own circuit board, they require various electronic components for adjusting the input and output voltage levels and protection against polarity reversal and short-circuiting. AMSYS offers a good solution here with the small, inexpensive pressure sensor modules such as the AMS 2710.

The AMS 2710 series are ready-to-install industrial pressure sensors, which are mounted on a print-ed circuit board and can be easily installed in a housing without additional components. They are available for absolute, relative and differential pressure measurement in a wide pressure range from 5 mbar up to 2 bar. The modules are also available as bidirectional differential versions (for negative and positive pressure measurement).

Individually calibrated and compensated

These extended pressure sensors have a 0..10 V voltage output at 12..36 V supply. Due to their ro-bust, reverse polarity protected signal output and current limiting, they are thus predestined for in-dustrial environments. Due to the different connection configurations, the AMS 2710 can be con-nected via solder contacts, a plug or a cable terminal strip. The PCB sensor modules are individually calibrated and compensated and achieve a total accuracy of 0.5 %FS in the entire temperature range (-25..85 °C) and in the pressure range > 200 mbar.

In terms of their functionality, the new PCB pressure sensor modules stand between OEM sensors, which have to be soldered onto PCBs with additional components, and ready-to-install, housed pres-sure transmitters. In addition to the simple connection to existing controllers, the modules can also be used to very easily manufacture individual transmitters with their own housing. Further variants exist with the AMS 2711 with 0..5 V voltage output. Customized pressure ranges (up to 10 bar) and other modifications are available on request.

Electronic Manometer with LED Display

Easily adaptable illumination and range definition via IO-Link

Sensor Technology

ifm has further developed its tried-and-tested generation of type PG pressure sensors with analogue displays, by focussing upon digitalising the sensors and expanding visualisation options. The redesigned display unit now offers a quick overview of the previously defined measuring ranges and limit values through a ring of coloured LEDs. Instead of manually applying markings to the display housing, the minimum, middle and maximum ranges can now be visualised using different coloured LEDs. Thanks to IO-Link, the desired measuring ranges can be defined quickly and easily and adapted to each application. The bright LEDs enable the user to see from a distance whether the pointer is in the green area or already close to the limit.

Measures up to 400 bar

Process values and additional information are continuously transmitted using IO-Link technology. Because data is transmitted in a purely digital form based on a 24 V signal, it is conversion and loss-free. The PG pressure sensors boast a measuring range from -1 to 400 bar. As with previous models in the PG product family, the sensors are equipped with a robust ceramic measuring cell. For maximum safety in critical applications, the measuring cell has a diagnostic function that displays the cell’s status.

Temperature resistant up to 150°C

The electronic manometers are used in the food industry and other industrial environments. To meet the prevailing requirements, two device variants were developed with differing approvals and technical properties. For example, the device variant for food applications is permanently temperature-resistant up to 150°C and will compensate for the dynamic temperature jumps that can occur in cleaning cycles. The sensors are supplied with different connection variants. For example, the sensors can be easily and safely mounted in containers or pipes using an Aseptoflex Vario connection.