Despite the efforts made over the last 20 years, an important potential remains to reduce energy consumption in energy intensive industry by 15-25%, which was confirmed in a survey in 2011 of the Belgian and Dutch industry showing that behavioral change is both an opportunity and a challenge to achieve energy efficiency. Moreover, energy management and behavioral changes can achieve up to 47% of this remaining energy efficiency potential, however, only a limited number of companies actually focus on managing energy.

Often, the main reasons given for not managing energy is lack of time, lack of resources, focus on production, focus on safety and that energy is not a focus area. Energy use is strongly linked to greenhouse gas (GHG) emissions. As the requirement for GHG reduction is likely to increase with increased requirements from the European Commission, it is probable that there will be increased pressure on industry to reduce their energy consumption. Managing energy could be a big contributor helping industry reduce their emissions. In addition it might also become a strong driver to stay competitive if the energy prices continue to rise. Managing energy is a management question and linked to behaviors rather than a technical solution. With regards to energy, the combination of these factors - people, systems, structure, skills and strategy - is referred to as an organization's Energy Culture. It is the shared mindset that creates and sustains an environment leading to continual improvement of the energy performance of the organization, focused on the behavior of the people of an organization and their impact on the energy use.

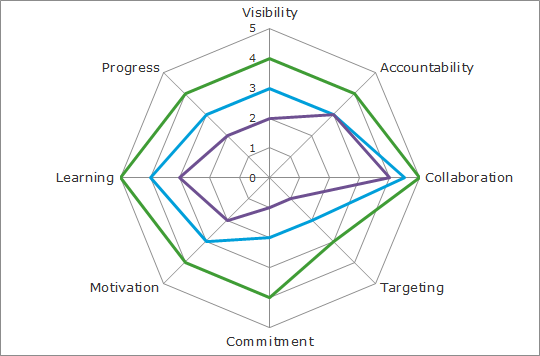

A new methodology has been developed to address the improvement of the energy culture for the energy intensive manufacturing industry. It draws inspiration from behavioral models (to understand specific behaviors and their underlying factors that influence them: threat, fear, response efficacy, self-efficacy, barriers, benefits, subjective norms, attitudes, intentions, cues to action, habits and reactance) and theories of change (models that show how behaviors change over time) and is a comprehensive approach to assess and improve an organization's Energy Culture and thereby reduce its energy costs. For theories of change, our approach is inspired by Kotter's 8-step process for leading change, including the following steps: Establishing a sense of urgency, Creating the guiding coalition, Developing a change vision, Communicate the vision for buy-in, Empowering broad-based action, Generating short-term wins, Never letting up and Incorporating changes into the culture. In order to assess the current status of an organization, it is evaluated on eight different dimensions covering the key elements in behavior models: Visibility, Accountability, Collaboration, Targeting, Commitment, Motivation, Learning and Progress. These eight dimensions are evaluated using a combination of tools such as surveys, interviews, workshops and observations. They are not just evaluated to get a better understanding of an organization's behavioral model and ability to change, but also to understand what tools have already been implemented in the organization and what tools could still be used to promote change. They are also used to identify what are the barriers to energy efficiency.

In each of the eight dimensions, an organization's performance is expressed as a maturity level. The result of the evaluation is presented as a spider diagram. An example of such a spider diagram can be seen in the figure below, where three different levels of maturity are shown expressed by the three different lines. Such a spider diagram is a visual way to quickly see where the biggest potential for improvement lays. After the assessment, an action plan is developed in order to improve the Energy Culture. This action plan depends on the organization's maturity level displayed above, its ambition, commitment and budget. Based on the different dimensions and their behavioral model, different systems and actions are recommended to be implemented and part of the action plan. This approach was successfully implemented at a chemical manufacturer in Belgium. The assessment was performed using surveys, interviews, workshops and observations. The result from the assessment was used to develop an action plan and this plan has now started to be implemented. DNV GL has been delivering Energy Management System services since early 2000. To date, DNV GL has supported a variety of industries with ISO 50001 gap analyses, implementation support, and certification. One requirement of ISO 50001 is to engage employees to implement a continuous improvement culture.

By Ulrika Wising, Head of Section Sustainable Energy Use Europe, DNV GL Belgium