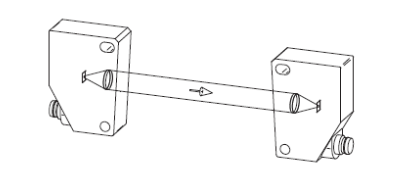

Many situations simply require the detection of an object, for example on a conveyor belt, table or transport trolley. However, it may not be possible to fit a reflector to use in conjunction with a retro-reflective sensor, or the receiving end of a through beam sensor. If the object to be detected lies in front of an interfering background, a diffuse sensor with background suppression could be the answer.

Such sensors use the principle of triangulation to measure the light intensity reflected by the desired target as well as the distance is it away. The minimum size of the object is then defined by the dimensions of the light beam being used. The distance to the object is configured by set screw, although some more advanced solutions have a “Teach-in” method that can be used.

Detecting objects

Featuring a red-light emitter, this visible light source makes it simple to adjust, even in conjunction with small objects. Laser-based sensors are capable of detecting objects with a size of just 0.1 mm, while pinpoint diode-based sensors have a 2 mm diameter spot of light at their focus. Their design is such that the object being detected can vary in both colour and material without detriment to the detection capability, while objects moving in the background do not trigger unwanted detection.

A prime example of a robust, IP67 rated solution, is the FHDK 14P5104 Series of photoelectric sensors from Baumer. These are packaged inside a 14.8 mm x 43 mm housing, are available with a wired interface, M8 or M12 4-pin fitting, and feature a sensing distance Tw of 30 to 500 mm. They are also electrically robust, with both short circuit and reverse polarity protection, with a PNP output supporting up to 100mA output current for both light and dark operate function. The front optics are made from PMMA and the integrated electronics uses a flashing yellow LED to indicate both issues with alignment or a soiled lens.

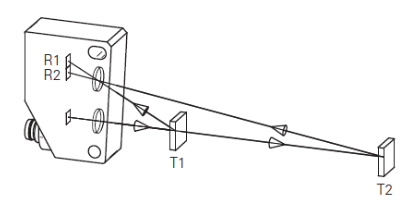

More accurate detections

Some visual detection solutions require a more accurate assessment of the object being detected. This could be to determine whether a label has been fitted correctly, or if the product is undamaged. Industrial vision systems based upon an IP-based networked camera together with an industrial PC is one approach. However, a solution dedicated to the task can be more appropriate. With the continuous growth in processing performance and memory, vision systems are now available with competent vision recognition performance packed into a standard video camera housing.

One such solution is the ZFV machine vision systems from Omron. These ultra-high-speed CCD cameras can be mounted in a fixed position or integrated onto a robot arm system. Depending on application, the camera line-up supports a sensing area from 5 x 4.6 mm, up to 50 x 46 mm. Each camera features its own light source in the form of eight red LEDs, providing a pulsed light, and the housing is IP65 rated.

The cameras are used in combination with an Amplifier Unit. Once trained, the system is then capable of providing a positive recognition response within 4 to 15 ms, depending on the type of image being recognised. The Amplifier Units can also be gang mounted. This allows the use of two or more cameras to analyse adjacent objects, such as an integrated circuit, checking orientation of the product, or that bottles with their barcodes are correctly positioned. As the Amplifier Unit is only IP20 rated, it must be appropriately mounted. Successful recognition can trigger an NPN or PNP output, while images can additionally be logged to a memory card.

Sensing of liquids

Sensing of liquids in tanks and pipes brings its own set of challenges. Some liquids foam up, while others, with lower viscosity, have a tendency to cling to surfaces. This can cause issues in sensing quality. The CleverLevel LBFH series from Baumer are compact level switches that integrate a bright LED, visible around 360°, to indicate the sensor status. Available in an IP69K housing, they are suitable for food and beverage, pharmaceutical and chemical applications. Based upon a capacitive resonant circuit measurement technique, they make use of frequency changes that occur in the presence of the material being detected.

In some environments, the object cannot be reliably detected due to variations in the object’s colour, or due to the material it is made of. There are also challenges in detecting transparent materials, such as plastic films and glass bottles. In such situations, ultrasound sensors, either in through-beam or reflective form, are an ideal candidate. One candidate here is the UB800 series from Pepperl+Fuchs, a single head system in a short, 40mm design.

The sensors are capable of detecting items in the 50 to 800 mm range, with a dead band between 0 and 50 mm. They provide immediate indication of their status, with a green indicator showing the sensor is powered, while yellow indicates that an object is in the evaluation range.

The challenge of Industry 4.0

As Industry 4.0 and more digitalisation drives more internetworked automated manufacturing systems, more and more sensors will be required to develop these platforms. With enormous variety in materials, liquids and objects being sensed, it is a challenge to determine precisely which sensor best meets the needs of the application. Suppliers are providing a wide range of solutions, with more features integrated into them. Highly visible indicators provide visual feedback on whether power has been applied, and whether an object has been detected. They are also increasingly configurable, from high-end, camera-based vision systems, down to the relatively simple distance and liquid detection sensors. Regardless of what is to be detected, it is highly likely that there is a sensing solution that matches the task’s needs.

By Steve Herd, Head of Customer Proposition and Product Management at Distrelec