A range of innovative bearing solutions are helping vehicle manufacturers to produce more compact, lighter vehicles, with improved fuel consumption and reduced CO2 emissions.

The latest of these innovations is the FAG wheel bearing, which is more compact and 10% lighter than its predecessor. The bearing also offers simplified mounting via a unique self-centring, axial spur gear teeth design.

First developed in 2004, the wheel bearing has since moved into series production, with BMW already using the unit on its new X1 model. A reduction in weight of 10% typically amounts to an overall weight reduction of 1kg for a four-wheel vehicle.

With a spur gear teeth design in which the wheel bearing and axle journal are connected axially rather than radially, the bearing module is lighter and can be mounted clearance-free. Driving characteristics are improved and automotive manufacturers benefit from a simple mounting process and the associated cost reductions.

Previously, the gear teeth of the axle journal of the input shaft were pushed axially into the wheel bearing. Here, the drive torque was transferred via longitudinal gear teeth.This mounting method has proven itself over many years; however, it has a number of disadvantages. The relatively solid, heavy component requires a certain amount of clearance to enable easy mounting. Also, loads that occur during vehicle operation can lead to the assembly becoming loose, resulting in loss of comfort and higher noise levels, as well as possible failure of the bearing.

Up to now, the solution has been to reduce the radial clearance to zero in the design phase. However, this requires the use of complex, costly mounting technology.

The wheel bearing with spur gear teeth is better equipped to deal with the loads that occur during vehicle operation. The spur gear teeth ensure positive connection between the wheel bearing carrier and the input shaft, which simplifies mounting considerably. The self-centring axial gear teeth are simply placed on the axle journal and fixed in place by using a central screw. Unlike radial gear teeth, this mounting procedure does not require significant force. The bearing remains clearance-free, but securely held in place during vehicle operation.

Having four lighter wheel bearings on the vehicle reduces the unsprung masses, which improves the driving characteristics and contributes to a reduction in CO2 emissions.

Replacing plain with rolling bearings

Another bearing solution is the INA lightweight balancer shaft and rolling bearing assembly. This is currently being used on the Mercedes-Benz OM 651, a 2.2 litre, four-cylinder diesel engine that produces up to 204ps and 500Nm torque. The weight of the INA balancer shaft and bearing assembly are optimised in order to improve engine efficiency and reduce overall fuel consumption.

By replacing conventional plain bearings on the balancer shaft with rolling bearings, friction is reduced. Using needle roller bearings with a raceway directly on the shaft reduces friction by up to 50% over the whole speed range.

At the development stage, by analysing engine load conditions, Schaeffler was able to optimise weight distribution. This enabled the width of the bearing to be reduced, which meant that the weight of the shaft could be cut by more than a third. This equates to an engine weight saving of 0.75kg.

When designing the complete drive train for the OM 651, Mercedes was then able to utilise this reduced shaft rotational inertia. The lower mass moment of inertia reduces the load in the power train, therefore improving the acoustic characteristics. In addition, the narrower raceway improves the oil mist supply to the rolling bearings, enabling a simpler system design without oil feed holes, reducing manufacturing costs. The engine requires alower through put of oil, so the oil pump can also be made smaller. All of these technical improvements meant that engine fuel savings of around 0.5% to 1% were achieved.

With the global market for four-cylinder engines standing at almost 50 million systems per year, the INA light weight balancer shaft assembly offers huge potential for reducing engine fuel consumption and emissions. For example, based on an average reduction in fuel consumption of 1% over the life of an engine, and calculated for a vehicle mileage of 250,000km, this would lead to approximately175 litres of fuel savings. Even if only 25% of all four-cylinder engines were fitted with INA lightweight balancer shaft assemblies, this would still reduce harmful CO2 emissions by around six million tonnes per year.

Larger vehicle, greater savings

Trucks, SUVs and light vans are also benefiting from innovative bearing solutions. By replacing ‘line’ contact associated with conventional tapered roller wheel bearings with a new design based on ‘point’ contact using ball bearings, an innovative ‘twintandem’ wheel bearing unitt has been developed, which reduces friction by around 50% over conventional tapered roller wheel bearings. This equates to a 1.5% reduction infuel consumption.

The twin tandem design is based on replacing the rows of tapered roller bearings with two rows of ball bearings in each case. A double-row tapered roller bearing therefore becomes a four-row ball bearing. Replacing the line contact of the tapered rollers with the point contact of the balls eliminates rib friction and reduces overall friction by 50%.

The twin tandem bearing also has a lower operating temperature compared to conventional tapered roller units, therefore improving the service life of the lubricants. Cornering stiffness is also increased.

The interchangeability has also been carefully considered of the new twin tandem with conventional tapered units. The twin tandem is designed to cater for the use of sensors (such as ABS sensors) and installation in the wheel carrier is identical for conventional tapered roller wheel bearings.

Assuming a vehicle emits 300g/km of CO2 over a distance travelled of 15,000 km per year, the reduction in CO2 emissions resulting from the twin tandem unit will be 67.5kg per year per vehicle. Fuel consumption is also reduced by 1.5%, giving a reduction of 40 litres per year for an average light truck travelling 15,000 km per year.

25% reduction in CO2 emissions

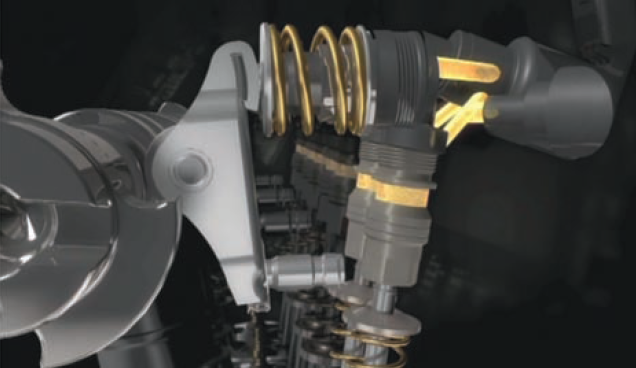

A collaborative development between Schaeffler and Fiat Powertrain has resulted in a new engine system, a fully variable hydraulic valve control system, which reduces vehicle fuel consumption and cuts CO2 emissions by up to 25%.

UniAir is a fully variable hydraulic valve control system that will make its debut on Fiat’s new Alfa MiTo 1.4 MultiAir. This is the first vehicle within the Fiat Group to be equipped with this technology.

As well as offering car manufacturers a more compact valve control system, UniAir will help the automotive industry meet future CO2 emissions targets for passenger cars. UniAir provides improvements in start-up, part load and acceleration behaviour of the vehicle. During the engine warm-up phase, for example, hydrocarbon (HC) emissions are up to 40% less and nitrogen oxide (NOx) is reduced by up to 60%. In addition, UniAir offers a greatly improved driving experience, through more power, higher engine torques and optimised engine response.