Parker Hannifin has extended its ETH range of high force electro thrust cylinders. The ETH125 combines the advantages of hydraulics with those of electronics, profiting from its rugged design and the resulting long service life. Typical applications include material forming and press applications, food processing and packaging machinery, industrial automation and other applications where users are looking for an energy saving electro cylinder for precise positioning and force control.

The ETH125 is available with screw leads of 10 and 20mm. It is able to achieve thrust forces of up to 114000N, travel speeds of up to 833mm/s and accelerations of up to 10m/s2. It comes in defined standard travel lengths between 100 and 2000mm, but is configurable in steps of 1mm also. With a repeatability of up to 0.03mm, the cylinder is up to all tasks requiring precise motion, positioning, setting and actuating.

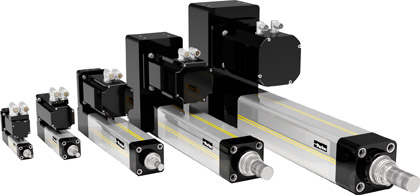

The ETH125 is available with parallel or inline motor configuration. Thanks to a variety of mounting options, which can be chosen according to customer requirements, customer may combine the cylinder with many different motors and gearboxes. The number of rod end configurations and mounting options offer the flexibility to integrate the electro cylinder into customer application. Available sensors and cables can be directly immersed into a groove in the ETH profile, which may then be protected by a cover. This ensures a smooth surface for easy cleaning and safe handling.

The ETH is offered as standard in IP54 format with galvanised screws, but is also available with stainless steel screws or in full IP65 format with additional coating protecting the cylinder against aggressive chemicals. Thus meeting the needs of more demanding environmental conditions.

Simplifying product selection and mounting, Parker can also provide a complete drive train, including matching servo drive controllers, motors and gearboxes. All these components can be selected and programmed easily with the easy-to-use Compax3 software-tools.

Electro Cylinder Range ETH

offers thrust sizes up to 114000N

- by Parker Hannifin PLC Pneumatic Division Europe

- August 1, 2014

- 93 views