Spuntech's North Carolina plant's Profibus network runs seven PLCs with approximately 350 nodes. Managing the system presented a challenge as random and intermittent instances of nodes drop on and off the network, cutting the lines of communication to the monitoring station.

N.R. Spuntech Industries is a leading manufacturer of non-woven textiles, specifically the spunlace fabric that is ultimately used in the medical, construction, and agricultural industries as well as in a wide variety of consumer products.

The company runs three production facilities: two in Galilee, Israel and one - its newest - in Roxboro, North Carolina. This 20,000 square meter facility houses a state-of-the-art production line that transforms raw fibers into rolls of finished fabrics via a complex and tightly monitored series of operations including opening, cording, drying, and packaging.

Challenge: Mystery issues turn the workday into a minefield

Paul Hall is the Process Control and IT Manager for the North Carolina plant. He is responsible for all the technology processes and the machines that enable them - from the production line assets that make the fabric to the computers and databases that manage them.

The North Carolina plant's Profibus network runs seven PLCs with approximately 350 nodes. Though Profibus is a well established and proven technology and a best practice in industrial automation, it is - like any technology - not one hundred percent foolproof all of the time. Paul was having some challenges managing his system - encountering random and intermittent instances of nodes dropping on and off the network. Though these types of issues are typically minor concerns, they did need to be addressed. Each occurrence cut the lines of communication between the monitoring station and critical pieces of equipment, leaving Paul without eyes or ears on the production floor.

As a result of these issues, Paul was forced to stop the production line multiple times, sometimes for hours. The resulting cost in lost revenue was substantial. Unfortunately, the system was behaving like the car that makes a funny noise until you reach the mechanic's garage and then runs perfectly. As is often the case with technology, the network issues would happen without warning, without any pattern, and would often self-correct without providing any clues as to what had triggered them.

The situation was not optimal. Unable to physically or programmatically determine the root of the problem, Paul had to approach each new day ready for anything. The unresolved problem felt like a ticking time bomb - keeping Paul up at night and adding stress to his days.

Strategy and Tactics: Simplicity. Speed. Service.

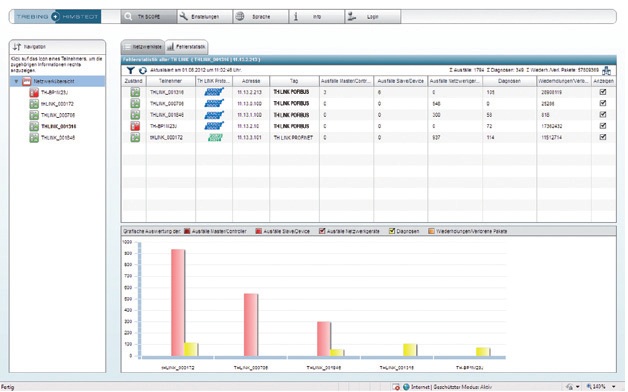

Paul decided to take a proactive approach and began researching various monitoring and diagnostic solutions that would enhance his Profibus network by providing more in-depth and accessible visibility into network performance. He considered products from several companies, but - after careful review - chose to implement Trebing + Himstedt's TH LINK (hardware that provides a central network access point) and TH SCOPE (diagnostics software application).

"There are a number of companies that offer similar products, but Trebing + Himstedt was the only one that offered the exact solution I needed," Paul explained. Paul found that TH LINK was the only product that offered OPC compatibility right out of the box. This capability allowed him to tie TH LINK directly into his existing SCADA system so that he could start monitoring the real-time health of his network almost immediately. It also meant that his technicians and line operators could centralize all their tasks and activities on one system, instead of having to jump from one PC to another in order to monitor or diagnose network issues.

"The Trebing + Himstedt team went above and beyond to help us establish the initial communication link via a third party product," Paul said. "They jumped right in and helped us quickly navigate system-specific considerations so that everything went smoothly the first time around."

Paul appreciated the "plug-and-play" aspect of TH LINK as well as the simple yet powerful TH SCOPE interface. "It was very simple to set up and configure," he said, adding, "We were able to start troubleshooting right away."

Performance Results: "TH LINK paid for itself in the first week."

Within the first week of having TH LINK and TH SCOPE on-site, Paul was able to use it to isolate and solve a substantial and critical problem. Although TH LINK had not yet been fully integrated at the time, even as a stand along system it was able to troubleshoot the system with great success. When the recurring issue that had plagued the plant's network reappeared, Paul put the Trebing + Himstedt products to work and was instantly monitoring the situation via his new tools.

With the access and visibility provided by TH LINK and TH SCOPE, Paul was able to quickly identify which unit was causing the issue. When this problem had occurred in the past, Paul and his team could only guess at the cause, which could have been anything from a faulty part to a loose connection. Using TH LINK and TH SCOPE, diagnosis was fast, accurate, and detailed. They pinpointed the cause of the issue and made the necessary adjustments and repairs. They have not had any down time related to that issue since, saving the company a great deal of money.

Looking forward, Paul is already planning on additional implementations and integration. "The proactive part of our plans was put on hold while we handled the crisis at hand," he said. "But, now that we've resolved that long-standing problem, we're looking forward to taking full advantage of the products' capabilities." Plans include tapping into the ability of TH LINK and TH SCOPE to not only monitor in real-time, but to also help identify and highlight predictive trends that will enable Paul to be much more proactive in his management of Spuntech's plant network and assets.

In a very short period of time (three months), Paul has solved a long-term issue, saved his company a substantial sum of money, and made critical parts of his job a lot easier. As Paul puts it, "TH LINK is almost like having a Profibus technician in a little grey box. I readily recommend Trebing + Himstedt, TH LINK, and TH SCOPE and will definitely use them again in the future."