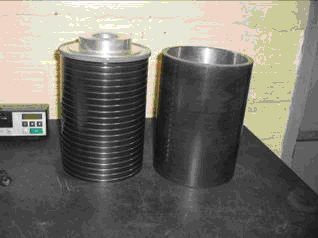

Specialised in surface treatment of parts subject to wear, Métallisation Nord Industrie’s Placrox II thermo-chemically formed ceramic coating is based on chromium oxide. Crystallographically bonded to the substrate, it offers the much better wear and corrosion resistance than any flame sprayed chromium oxide. The coating, in layer thicknesses of 50 to 100 µm, can applied on all base materials including steel, cast iron, stainless steel, titanium, and so on. It is in the form of slurry, which is directly applied on the metallic substrate. Through a multiple-cycle thermo chemical process, this slurry becomes dense until a totally non-porous ceramic that is chemically bonded to the substrate is formed. The resulting coating has no cracks or flaks. Resistant to sea water and most acids, the extremely hard (2000 HV) coating can also resist temperatures up to 700°C with no need for modification.

Edited by: Teoman Tugsuz