It’s a topic not often mentioned up front with heat recovery projects, but one that will have a significant impact over the life of a project. I’m talking about heat exchanger fouling.

Heat exchangers are key components of a system, used to transfer heat from one medium to another. In this article, I will focus on fouling due to exhaust gas. In short, fouling is the buildup of “stuff” on your heat exchanger surfaces that reduces the effectiveness of heat transfer.

This buildup acts as an insulator and reduces the amount of heat transfer that can take place. The most common fouling agent I’ve seen is simply soot from combustion. Soot is basically carbon dust and unburned fuel that sticks to the heat exchanger tubes. How much do you need to worry about fouling?

Well that depends on a lot of factors, but if you have the right information and expertise you can often overcome the issues that fouling presents.

The negative effects of fouling heat exchangers

1. Reduced Heat Transfer

Fouling compounds tend be pretty bad thermal conductors, so a buildup of material on heat transfer surfaces will reduce the amount of heat you can extract from your source. As a result, you will get less heat from your heat source than you planned, which could throw off the economics of the project.

2. Increased Back Pressure

Backpressure refers to the amount of restriction on the exhaust of combustion equipment. Think about an engine where the exhaust pipe has been partially covered. If the exhaust cannot escape as fast as usual, then the engine is at risk of not working properly or even failing completely. Now imagine fouling buildup on the inside of that exhaust pipe. The more that gets deposited on the pipe walls, the less area there is for exhaust flow and the higher the backpressure will be. While these issues can hamstring a heat recovery project, they can be avoided through proper planning and understanding of what causes fouling.

Causes of fouling

The primary drivers of fouling are the fuel you use and how you burn it. Essentially, the more carbon atoms present in the fuel, the more fouling to expect (see diagram below). Also, burning the fuel in a rich mixture will produce leftover fuel in the exhaust, leading to fouling. It just so happens that higher carbon fuels (diesel, heavy fuel oil) tend to be burned in a rich mixture, providing the perfect environment for fouling.

Heat exchanger fouling occurs on many applications ranging from cement kilns to smelter exhaust, to boilers. For this article I will focus on two types of fuels in power generation applications.

1. Gaseous Fuels

Natural Gas, Propane, and Biogas are all low carbon content fuels that have a low propensity for fouling. These fuels are usually premixed in a lean fuel-to-air ratio, meaning that there is not much, if any, unburned fuel in the exhaust. Low carbon and low unburned fuels means low fouling. The notable exception to this is landfill gas. During the methane production process in a landfill, a chemical family called siloxanes can leech from consumer products (like shampoo) into the gas stream. If not properly scrubbed before combustion, siloxanes can create a rock-like coating on the interior surfaces of an engine and subsequent heat exchangers.

2. Liquid Fuels

Diesel, Bunker Fuel, and Heavy Fuel Oil have much higher carbon content compared to gaseous fuels. In addition, these fuels tend to be burned at a slightly rich fuel-to-air ratio. This results in more unburned fuel and carbon in the exhaust stream and serious fouling problems. Fouling that affects system performance can occur in a matter of days, if there are no preventive measures in place. I have seen systems on liquid fuels that have reduced performance by as much as 30% in a week of running without a cleaning system. To sum it up, gaseous fuels do not pose a significant fouling threat and can be kept under control through occasional manual heat exchanger cleaning. Liquid fuels are much more difficult to keep in check.

Solutions to fouling

So what can be done to combat fouling? Here are some recommendations for liquid fuel applications.

1. Heat exchanger design

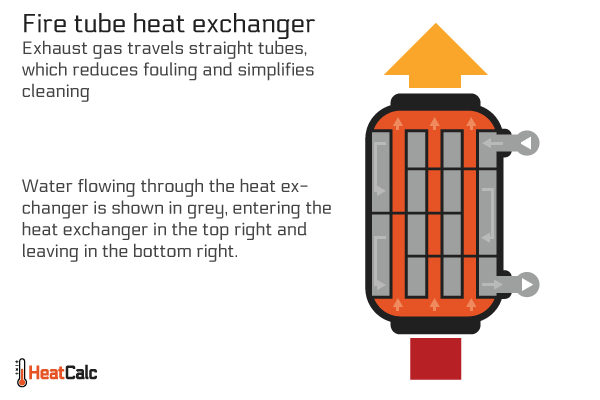

A lot of the headache from fouling can be avoided through informed design choices. Fire tube or smoke tube heat exchanger – Arguably, the most cleanable design is a shell and tube style heat exchanger in which the exhaust travels through the tubes with no bends. Since the dirty exhaust is only in the straight tubes, you can run a brush all the way through each tube to clean them. Smooth tube over finned tube - Many heat exchangers will use fins to increase the heat exchanger area. While this may help the heat transfer, the small gaps between fins are magnets for fouling.

2. Oversizing

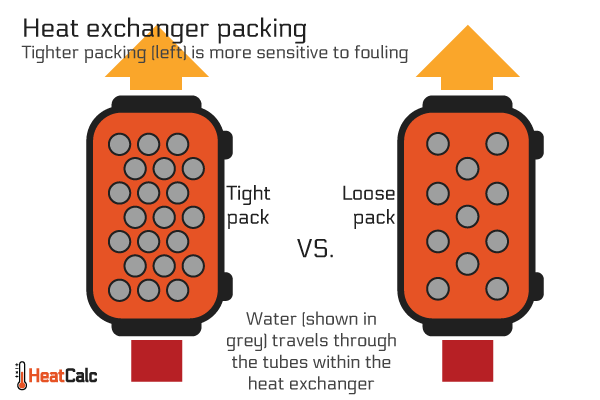

Knowing that fouling will occur and reduce heat exchanger effectiveness, you can oversize your equipment to allow your process to continue despite some fouling. The amount of oversizing is a judgement call and needs to be assessed for each application. Reduce packing density – Packing more tubes into a given space will reduce the size and cost of a heat exchanger at the cost of access and flow restriction. As fouling builds up, the design on the left will experience significant blockage leading to backpressure increase. Increasing the spacing will not only make the design more tolerant to fouling but will also allow for better access for manual cleaning.

3.Cleaning

The most effective way to prevent fouling is to stop it before it gets out of control. Regular cleaning of the heat exchanger is the best preventive measure. Cleaning is generally divided into two categories. On-line Cleaning - On-line cleaning refers to methods for removing fouling without shutting down the heat source (engine, boiler, etc). Often, heat recovery projects are auxiliary systems that aim to avoid causing a shutdown of the primary process, making on-line cleaning crucial. Most heat exchanger suppliers offer an integrated cleaning system to remove fouling without taking the system offline. These are often a high pressure fluid spray (water, air, or steam), a mechanical device (hammer, scraper), or even a sonic horn. At set intervals (or when the differential pressure across the heat exchanger exceeds a threshold value) the spray will dislodge fouling buildup. Typically, this type of cleaning will not remove all the fouling, but instead will keep it to a manageable level. Off-line Cleaning - At some point, the heat source will need to be taken offline for maintenance. These times are prime opportunities to do a thorough, manual cleaning of the heat exchanger.

By Matt Gutschow, Co-Founder of heatcalc.com