Schaeffler has expanded its popular BEARINX rolling bearing calculation software with a new module for designing rope and cable sheaves. Modern design calculation and simulation tools play a key role in increasing the efficiency of rolling bearings. The BEARINX-online Easy RopeSheave software enables design engineers to calculate the static load safety factor and rating life of both single and multiple rope sheave bearings. The software is available exclusively online and can be used free-of-charge. Initial registration takes little time and the user can begin calculation work immediately.

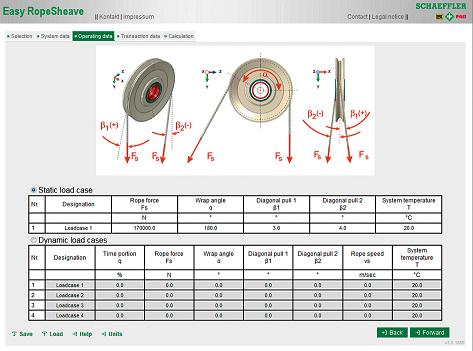

At http:\\bearinx-online-easy-ropesheave.schaeffler.com users can quickly and safely browse and compare a range of different rope sheave bearing designs. The self-explanatory menu and navigational tools enable users to enter data quickly and easily for modelling, bearing selection and operating data.

Technical data on rolling bearings, deep groove ball bearings and tapered roller bearings manufactured by Schaeffler are stored in a database. These can be accessed and integrated into the design calculation process at any time. Application-specific parameters, such as the rope sheave material, the integration of a bush between the bearing and plastic rope sheave, precise data on the bearing's internal geometry, or the influence of system temperature on bearing clearances, can also be considered for design calculations.

The software enables users to calculate, display and document the specific bearing loads in detail, while taking operating and environmental conditions into account - even for complex system and machine designs. During calculations, the software considers the contact pressure on every single rolling element.

The dedicated software module for rope sheave bearing supports even enables multiple adjacent rope sheaves to be calculated precisely. It takes into account factors such as the non-linear elastic deflection behaviour of the rolling elements, contact angle shifts in radial ball bearings caused by the load, elasticity of the axis, and changes in the real contact pressure depending on the skewing and profiling of the rolling elements.