THERMAL IMAGING IN AN R&D ENVIRONMENT

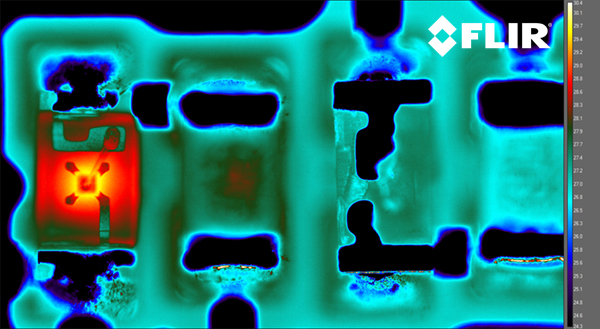

Thermal imaging cameras use thermal radiation, which is not detectable by the human eye, but can be converted into a visual image that depicts thermal variations across an object or scene. Covering a part of the electromagnetic spectrum, thermal energy is emitted by all objects at temperatures above absolute zero, and the amount of radiation increases with temperature. FLIR's thermal imaging cameras are used for capturing and recording thermal distribution and variations in real-time, allowing engineers and researchers to see and accurately measure heat patterns, dissipation, leakage, and other temperature factors in equipment, products and processes. Some of these cameras can distinguish temperature changes as subtle as 0.02°C. They feature state-of-the-art detector technology and advanced mathematical algorithms for high performance and precise measurements from -80°C to +3000°C.

COOLED AND UNCOOLED CAMERAS

There are two classes of thermal imaging camera systems available on the market today: cooled and uncooled systems. The component costs for these two classes of systems can be quite different, making it extremely important to decide which way to go.

COOLED THERMAL IMAGING CAMERAS

A modern cooled thermal imaging camera has an imaging sensor that is integrated with a cryocooler. This is a device that lowers the sensor temperature to cryogenic temperatures. This reduction in sensor temperature is necessary to reduce thermally-induced noise to a level below that of the signal from the scene being imaged. Cooled thermal imaging cameras are the most sensitive type of cameras and can detect the smallest of temperature differences between objects. They can be produced to image in the mid-wave infrared (MWIR) band and the long-wave infrared (LWIR) band of the spectrum where the thermal contrast is high due to blackbody physics. Thermal contrast is the change in signal for a change in target temperature.

UNCOOLED THERMAL IMAGING CAMERAS

An uncooled infrared camera is one in which the imaging sensor does not require cryogenic cooling. A common detector design is based on the microbolometer, a tiny vanadium oxide resistor with a large temperature coefficient on a silicon element with large surface area, low heat capacity and good thermal isolation. Changes in scene temperature cause changes in the bolometer temperature which are converted to electrical signals and processed into an image. Uncooled sensors are designed to work in the Longwave infrared (LWIR) band, where terrestrial temperature targets emit most of their infrared energy. Uncooled cameras are generally much less expensive than cooled infrared cameras. Uncooled cameras tend to have much longer service lives than cooled cameras under similar operating conditions.

COOLED CAMERAS FOR R&D APPLICATIONS

When is it better to use cooled thermal imaging cameras for R&D/ science applications? The answer is: it depends on the application requirements. If you want to see the minute temperature differences, need the best image quality, have fast moving or heating targets, if you need to see the thermal profile or measure the temperature of a very small target, if you want to visualize thermal objects in a very specific part of the electromagnetic spectrum, or if you want to synchronize your thermal imaging camera with other measuring devices, then a cooled thermal imaging camera is the instrument of choice.

SPEED

Cooled cameras have much higher imaging speeds than uncooled ones. High-speed thermal imaging allows microsecond exposure times that stop the apparent motion of dynamic scenes and permit capturing frame rates exceeding 62,000 frames per second. Applications include thermal and dynamic analysis of jet engine turbine blades, automotive tire or airbag inspection, supersonic projectiles, and explosions to name a few.

SPATIAL RESOLUTION

Cooled cameras typically have greater magnification capabilities than uncooled cameras, because they sense shorter infrared wavelengths. Because cooled cameras have greater sensitivity characteristics, lenses with more optical elements or thicker elements can be used without degrading the signal to noise ratio, allowing for better magnification performance.

SENSITIVITY

How do you get a feeling of the benefit from a 50mK sensitivity uncooled thermal camera in comparison to a 20mK sensitivity cooled thermal camera? The cooled camera can still see most of the thermal signature of the handprint, whereas the uncooled cameras only show the partial remains of the handprint. The cooled camera clearly can detect smaller temperature differences and for longer durations than the uncooled camera. This means the cooled camera will provide better detail on your target and help you detect even the faintest of thermal anomalies.

SPECTRAL FILTERING

One of the great advantages of cooled thermal cameras is the ability to easily perform spectral filtering in order to uncover details and take measurements that otherwise would be unachievable with uncooled thermal cameras. The end user wanted to measure and characterize the combustion of coal particles within a flame. Using a "see through flame" spectral infrared filter, we filtered the cooled camera to a spectral waveband where the flame was transmissive and therefore we were able to image the coal particle combustion. The first image is without the flame filter and all we see is the flame itself. The second is with the flame filter and we can clearly see the combustion of coal particles.

SYNCHRONIZATION

Precise camera synchronization and triggering makes the cameras ideal for high-speed, high sensitivity applications. Working in snapshot mode the FLIR A6750sc is able to register all pixels from a thermal event simultaneously. This is particularly important when monitoring fast moving objects where a standard uncooled thermal infrared camera would suffer from image blur. With an uncooled microbolometer camera, you would not catch the coin at all due to the inability to trigger that type of detector and if you did by luck it would be blurred.

THERMAL CAMERAS FROM FLIR

The higher performance A6750sc, A8300sc, SC6000, SC7000, SC8000, X6000sc, and X8000sc cooled cameras offer ultra-fast, ultrasensitive performance in the MWIR and LWIR spectral bands, while the FLIR A6250sc operates in the NIR spectral band. These cameras provide superior measurement capabilities in challenging setups for fast motion and thermal events, wide temperature range, small amplitude phenomena, multispectral analysis or very small object evaluation. FLIR also offers a wide range of uncooled cameras, from entry-level bench test kits up to higher end systems like the FLIR T650sc. Dedicated lenses and software will adapt your camera solution to your specific application. To know exactly which cooled or uncooled camera you need, please contact your FLIR representative.