Last year, Ming Tai implemented Markforged 3D printer into collaborating design service. 3D Printing makes manufacturability no longer the limiting factor in product design.

Obviously, it not only optimizes the process of spring design, but also brings huge advantages to benefit customers and Ming Tai as follows:

The advantage of this new process will be:

- Fast sample build

- Low cost

- Optimized design

- Manufacturability

- Time to market

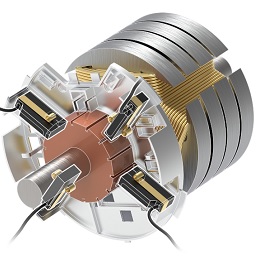

This innovation case is a spring motor drive system, which extends and retracts a screen. Let me share a case with you. Not only the space is limited but the shape of the space is cylinder. To fulfill this limitation and to bring the biggest effective from this space, Ming Tai designed a mechanism like below.

Like the common design, one spring is not possible to achieve the torque we need. As you can see, we use three constant torque springs in one mechanism, in the middle, is an output drum, connect with three springs. So it can generate three times of output torque compare to only one spring.

This design can achieve the goal of providing the biggest torque in a limited space.

It's also worth mentioning that the way of connect the spring and the output drum is a best example to show the benefit of using 3D printing technology to make sample.

This connecting method is easy to assembly, comparing to using screw to connect.

However, if we want to make this part with machining, the cost will be very high, 3D printer just overcome this big issue: the sample fee is too high for development stage.

Regarding to the connection method of mechanism to their part, they send us the tube of their product, so that we can ensure the part is just fit into the tube, if not, we can adjust the printed part before shipment.

When customer receives the part, they can just simplify assembly the part and start to test the performance.

Our printer is highly precise in dimension and the strength is enough for engineering use. We are expecting to receive your inquiry for the new product development. We are more than welcome to provide our printing service for you. Let us explore with this new technology together.