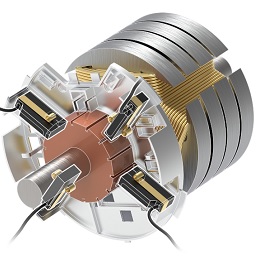

Ming Tai Industrial Co. manufactures both single coil type constant force springs and twin coil type constant force springs for carbon brush application. The catalog not only introduces main applications of spring in the carbon brush industries, including Commutator, Slip ring, Grounding, and Lightning protection; but also briefs how Ming Tai Industrial Co provide customer with best design and highest quality manufacture service for constant force spring to meet your need for carbon brush application.

Constant Force Springs for Carbon Brush Application

A catalog from Ming Tai

- by Ming Tai Industrial Co., Ltd

- September 28, 2020

- 27988 views