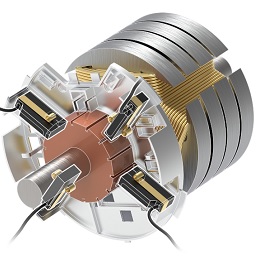

The constant force springs from Ming Tai Industrial Co. are designed for carbon brush holder application. They are used to hold carbon brush to make electrical connection steady to rotor of slip ring, and to commutator of brush motor. They make sure that the carbon brush works consistently by dependably exerting constant pressure to increase brush life and reduce electrical wear. Constant force springs benefit to users through exerting constant pressure for commutator and slipping ring in any brush length.

Compact design for overall motor size and slip ring

Moreover, they allow longer brushes to meet large commuter and slip ring requirement. Last, they reduce spark, lower influence of electromagnetic interference (EMI). When applied to carbon brushes, constant force springs are electromechanical conducting devices that connect to moving parts to conduct an electric current. Ming Tai’s constant force springs can be classified in two types: the Single Coil Type and the Twin Coil Type.