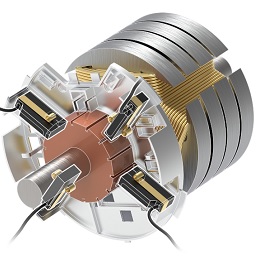

Ming Tai Industrial Co., develops a wide range of constant force springs with clips for carbon brush holder application. Constant force

springs are used to hold carbon brush to make electrical connection steady to rotor of slip ring, or to commutator of brush motor. It is widely applied to home appliance, electrical tools, automotive, railway and wind turbine etc. Constant force springs with specially constructed ensure the carbon brush works consistently by dependably exerting constant pressure to increase brush life and to reduce electrical wear.

For more detail information, please contact Ming Tai Industrial Co.