A lack of communication-combined with a short-sighted fixation on holding down factory capital expenditures-is incurring massive energy-inefficiency costs for manufacturers during the lifetimes of their production facilities, according to IHS Technology.

"There is a significant disconnect between those who make decisions regarding industrial capital expenditures, and those who are tasked with managing the costs of manufacturing operations," said Alex Chausovsky, manager and principal analyst, Motor-Driven Systems and Industrial Automation, at IHS. "Individuals making capital-expenditure decisions when building new industrial facilities rarely, if ever, consider the long-term costs associated with projects. As a result, these decision makers consistently place initial purchase price concerns ahead of total cost-of-ownership (TCO) considerations. This means that energy efficiency is not a factor in the decision-making process, and operators that take over these projects after their completion are often faced with much larger energy bills than they would have if the most efficient equipment had been specified during the construction phase of the project."

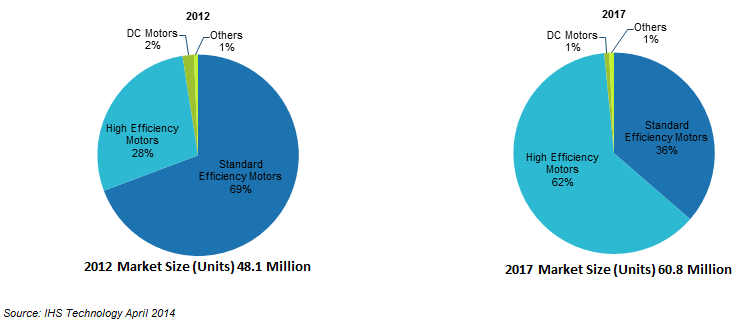

For factory operators, these energy bills can add up over the years. Take an average electric motor used in a factory, for example. The purchase price represents only 2 percent of the motor's lifetime costs. However, a full 96 percent of the motor's TCO is accounted for by its lifetime electricity usage-with the remaining 2 percent going toward repair and maintenance, according to multiple industry case studies. Electric motors used in industrial facilities and other settings consume nearly half of the world's electricity, according to the International Energy Agency (IEA). Furthermore, industry represents the largest single electricity-consuming market with 42 percent of total usage in 2006, vastly exceeding other areas, including residential and commercial.