Test stand operation for the testing of combustion engines, hybrid and electric motors requires high-precision measuring equipment. Friction power measurements in particular place very high demands on the measuring equipment. In order to meet these demands, the transducer has a standard accuracy class of 0.05. Particular emphasis has been placed on the robustness of the measuring equipment.

For nominal speeds up 24,000 rpm

The new XTREMA TORQUE series by MANNER has been specially designed as a short type with low rotor weight and mass moments of inertia. This is particularly important for electric motor test stands with nominal speeds of up to 24,000 min-1, especially given that these speed requirements must be expected to rise even further. This provides the test stand operator with an optimal set-up for future demands.

The high nominal speeds of up to 24,000 min-1 are no challenge for the XTREMA Torque design. It uses a DIN flange pattern that is compatible with HBM torque sensors and allows for easy integration into both new and already-built test stands with existing infrastructure. The large distance between rotor and stator of up to 10 mm is particularly noteworthy. In combination with the protruding pick-up, it affords strong protection against damage in case of bearing damage, as well as great ease of installation. Even lack of precision during assembly will not affect the transmission quality.

High temperature version for up to 160°C

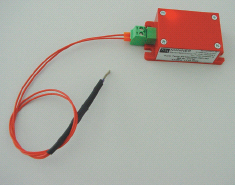

The optional hollow shaft supports complex test stand set-ups. Oil supply at the centre or actuator systems are not a problem. The series includes the following ranges: 200 Nm; 500 Nm; 1 kNm; 2 kNm; 3 kNm; 5 kNm and 10 kNm. Another special feature of our solution is the optional high temperature resistance of the measuring flange of up to 160°C and the optional protection rating IP67. This also ensures a high fatigue limit. The XTREMA TORQUE sensor includes a stator pick-up unit with built-in evaluation electronics, which provides the torque sensor with inductive feed and stands out for its compact design. With this design type, the interfaces for frequency output (F= 10 +-5kHz) and voltage outputs U= 0 +-10 V are available as standard. The system runs absolutely maintenance-free.

With the optional version (separate stator), the evaluation unit may be installed inside the control cabinet. This allows for the operation of the XTREMA Torque measuring flange and the pick-up at higher ambient temperatures in the range between -40°C and +160°C and with oil immersion. The associated tube design evaluation unit can output the classic analog signals at 0.. ±10V / 4..20mA or use the frequency output, but it also supports the output of digital signals via EtherCAT, CAN, Ethernet, EtherCAT or USB.