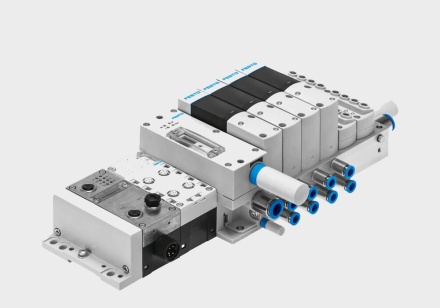

Festo Motion Terminal VTEM is the first pneumatic automation platform controlled using an app. Festo wants to lead pneumatics into Industry 4.0 era: indeed, it is possible to use motion apps to control one piece of hardware that can replace more than 50 individual components. From simple directional control valve functions to complex motion tasks, this solution allows users to standardize all applications while offering, as the company says, unparalleled levels of flexibility.

Valve technology for a wide range of products

Using apps reduces the complexity of systems, speeds up engineering processes, enables to continuously and flexibly adjust machine throughout its entire lifecycle. The new valve technology of the Festo Motion Terminal can be used for a wide range of products, functions and complete solution packages. The only prerequisite is a valve design with multiple degrees of freedom for actuation, as well as integrated data acquisition and processing suitable for a cyber-physical system. The reduction to just 1 valve variant provides both system builders and operators with huge economic benefits. With CPX, you can integrate the fieldbus or Industrial Ethernet nodes you need, plus additional I/O modules, subordinate installation systems such as CTEL, or CODESYS controllers with an OPC UA interface.

Please visit us at Hannover Messe 2019: Hall 15 / Booth D11