Six years of experience with the PCV system have helped Pepperl+Fuchs to shape the development of the PXV. The reading window of the PXV has been enlarged to 120 x 80 mm, meaning that the Data Matrix code tape is always located within the sensing range. Mounting and commissioning are easier, and plant availability is further improved. The reading window has an increased depth of focus range, allowing it to capture even more codes simultaneously and also guarantee position detection through multiple redundancy.

Unlike other systems available on the market, the PXV requires only a single 2-D camera, ensuring that irritation relating to track switches is excluded. The cameras in two-camera systems, on the other hand, can receive differing position signals in this scenario.

A certain degree of contamination on the code tape is often unavoidable during everyday operation. For this reason, the codes for the PXV have been expanded to 15 x 15 mm without compromising the resolution, and the "coarse-grained" design ensures that they are unaffected by contamination. Thanks to redundant detection, the system also cannot be disrupted by the destruction of individual codes. The code tape can be interrupted by a stretch of up to 80 mm without affecting position detection.

Innovative Safety Technology

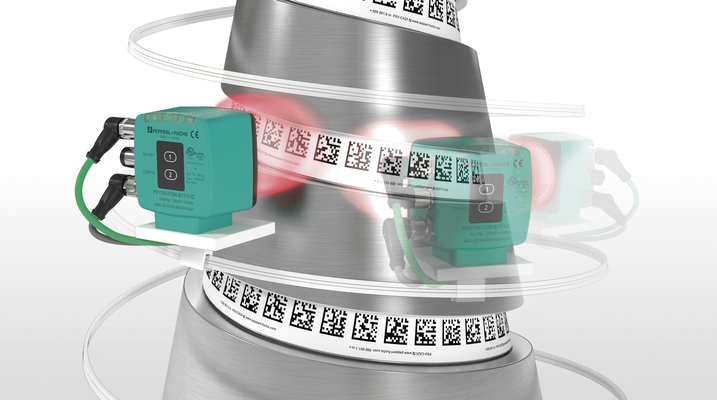

The new safePXV manages all that a single positioning system can with just one sensor. The new safety technology combines a 2-D reader with a three-colored Data Matrix code tape. The special code tape contains two overlapping Data Matrix codes in red and blue. The 2-D reader is equipped with two different colored LED rings—also red and blue. These rings are activated separately and then read just one Data Matrix code each. A SIL 3/PLe absolute position is always provided as the result.

By Armin Hornberger, Head of Product Management for Industrial Vision Components at Pepperl+Fuchs