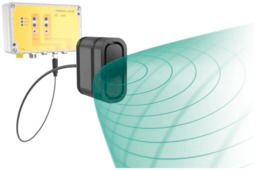

Radar (RAdio Detection And Ranging) is based on the transmission of electromagnetic waves and the detection of their reflection. This method makes it possible to determine the distance to objects in the path of the waves - or moving in their propagation range - at practically the speed of light. Pepperl+Fuchs has developed a series of compact sensors that make this robust principle of measurement usable for safeguarding machine movements in the materials handling and warehousing section.

Stable signaling, high EMC

The devices use the frequency-modulated continuous wave (FMCW) method, which ensures particularly stable signaling. The frequency band of 122-123 GHz ensures strong resistance to interference such as dust, steam, temperature fluctuations and weather conditions. In terms of electromagnetic compatibility (EMC), the devices achieve values comparable to classification E1 in almost every category. Reliable measurement is therefore guaranteed even in the case of conducted and high-frequency radiation with high interference levels. From the reflected waves and the derived measurement data, the devices can determine the distance, direction of movement and speed of objects in the detection area with high accuracy.

The sensors are housed in a casing measuring just 40x40x83 mm, so they can easily fit into tight spaces. The sensor head can also be rotated and swivelled so that it can be optimally aligned to the target area in practically any installation situation. Equipped with IP68/69 degrees of protection, the device is also well suited for harsh environments or constant switching between indoor and outdoor use. The new product series also allows great flexibility when it comes to electrical connections. In addition to the standardized M12 connector plug, connector types such as DEUTSCH or AMP Superseal are available specifically for use in vehicles.

Integration and diagnostics with CANopen

The integrated CANopen interface is responsible for transmitting measured values and parameterization commands. Integration into an existing CAN bus infrastructure is therefore very simple and possible without complex individual wiring. Device parameters and extended functions can be accessed either via the CAN network or with the help of the FDT framework program PACTware and a Device Type Manager (DTM). The sensor can thus be adapted to the respective application with minimal effort.

The connection via CANopen also opens up the possibilities for detailed status monitoring. This is an important prerequisite for use in safety-relevant applications, which is possible in conjunction with a fail-safe PLC. Thanks to the features of the sensors and their diagnostic capability, a single device is sufficient for safety level PL c (Cat. 2) and SIL 1. When integrated into a safety concept and with a redundant sensor design, the requirements for PL d (Cat. 3) and SIL 2 are met. Several devices can be used in close proximity to each other as they do not interfere with each other's function. A sampling rate of up to 200 Hz can be parameterized for applications with fast response times.

Adapted measuring mode

Electromagnetic waves are not reflected to the same extent by all materials; this is most pronounced with metal. With wood or plastic, on the other hand, the proportion of penetration clearly outweighs that of reflection. Depending on the type of application, it may make sense to fit corner reflectors made of sheet metal in the detection area. These are available as standard accessories.

However, the radar sensors are also able to largely compensate for the different reflective properties of the objects in the detection area or make use of them. For example, non-metallic objects can be specifically masked out by setting the appropriate parameters and selecting the measurement mode. In such an operating mode, the sensor then reliably detects the actual target object behind a partially transparent object that is located between them.

The radar sensors offer three different measurement modes for fine adjustment:

- "First object" - material-independent detection of the object closest to the sensor. Objects within the extension range or radius of action of the vehicle and boom are detected in all cases.

- "Strongest reflection" - detection of the object with the best reflection properties

- In "Fastest object" mode - detection of the object that moves towards or away from the sensor the fastest. This measurement mode is intended, among other things, for path monitoring and collision protection in driverless transport systems.

Application examples

Automatic reduction of maximum speed - Forklift trucks and other transport vehicles may and should drive faster on outdoor storage areas than in production halls and warehouses. However, a reduced maximum speed must be maintained there. An upward-facing radar sensor on the vehicle detects the hall roof on entry. The device gives the signal for the automatic speed restriction and for its lifting after the exit.

Height control for forklift forks - The higher the forks are, the lower the permissible speed of the forklift truck. The approval ratio between lifting height and load weight is also precisely defined. The radar sensor directed from the fork to the ground detects the lift height in "strongest reflection" mode and suppresses interfering objects. The height control can also be used to control the pallet insertion into the high rack: The sensor signal indicates whether the pallet base has reached the necessary height.

Collision protection for overhead crane - In the case of an overhead crane with several crane bridges mounted on its rails, the sensor monitors the distance between these elements. Slow travel is triggered when approaching and a safety stop is triggered if there is a risk of collision.