For reliable operation, mobile machines require sensors that can withstand the harshest conditions on a daily basis. Extreme temperatures, violent jolting, and vibrations are common challenges for these vehicles.

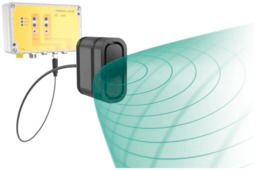

Ultrasonic sensors, which are used on vehicles like refuse collection trucks, must be extremely robust to guarantee safe operation. The sensors are used on the vehicles for a range of different applications.

Ultrasonic sensors help ensure efficient and virtually automatic operation. These sensors constantly monitor the lifting and set-down area of the refuse container, as well as automatically detect the container size. These features provide an extraordinary degree of flexibility without manual intervention on the part of the refuse collector, ensuring that both the vehicle and the refuse collector can complete their work quickly and safely.

When a refuse container moves toward the lifting unit of the refuse collection vehicle, the UB300-18GM40A ultrasonic sensor determines the size of the container. Both lifters are required to lift a large container with a volume of 1100 liters. The two lifters work together to transport the container. When two small containers or even a single small container are lifted, the lifters are controlled individually as required.

When the container is lowered after emptying, the area below the container must be monitored. Monitoring is important to prevent people from being injured or other obstacles being hit by the container and being damaged. A total of 4 UC2000-L2 type ultrasonic sensors monitor this area.

The fill level of the feed area for the refuse container on the vehicle is monitored using UC2000-30GM70 type ultrasonic sensors in one-way barrier mode. If the feed area is too full, the container can no longer be emptied correctly and refuse may fall off the vehicle. For this reason, when the rear area is about to overflow, the vehicle's hydraulic press is always activated in a timely manner by the ultrasonic sensor, and the refuse is pressed down toward the center of the vehicle.