When Anton Osswald founded the company in 1967, he was convinced that he could meet the wishes and requirements of his industrial customers by manufacturing high-quality linking elements. From the very beginning, the philosophy was: top quality, flexibility and absolute reliability. During the first few years, he employed his pioneering spirit in the construction of a series production line for bolts, folding spring bolts and clevises that was capable of manufacturing both standard parts and special solutions. By combining these products with a range of services, mbo Osswald soon made a name for itself as a specialist for clevises and clevis joints that swiftly travelled across the country's borders. The international demand for linking elements "Made in Germany" grew ever stronger and products from this highly competitive manufacturer are now shipped to more than 50 countries worldwide.

Innovation as a driver of progress

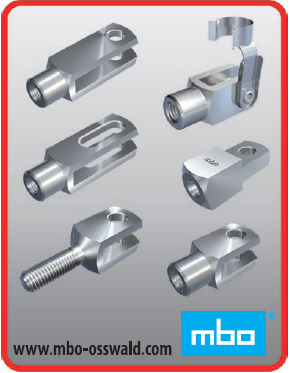

mbo Osswald has always been known for its new products, production methods and services. Thus, since 1996, the company has been manufacturing on state-of-the-art rotary transfer machines, which are now backed up by software-based production and quality monitoring capabilities. It also has a remarkably extensive, continuously developed, in-house range of steel and stainless steel clevises and angle joints. And the company was to set new standards with the introduction of new product lines such as clevises with male thread, mating pieces for clevises, hardened clevises and clevises with elongated hole. As a result of the desire to make the products even more resistant to failure due to corrosion, the portfolio was extended to include clevis joints and angle joints manufactured from grade A4 stainless steel.

What is more, customers are offered a specially tailored range of services to accompany the products, including modern, multilingual webpage with state of the art web shop.

Product development

And the continuous improvement in performance also includes the articulated joints. The growing demands placed on the parts mean that further development and new developments are a constant necessity. A high level of specialist knowledge and experience are required in order to fulfil complex, customer-specific requirements. Today 70 employees manufacture more than 12,000 standard parts and are specialists in the production of individual drawing parts to meet the market’s needs.