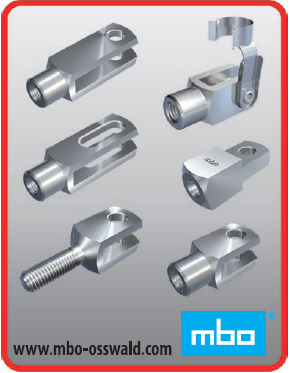

After the successful development of the eShop over the last two years, mbo Osswald is now further extending its online product range and offering spring cotter pins similar to DIN 11024, eye bolts in accordance with DIN 444 form B and axial joints with sealing cap. Standard linking elements have long been mbo Osswald’s speciality.

Spring Cotter pins

Among the machine elements, spring cotter pins with specifications similar to DIN 11024 are releasable connections and are used as retaining elements. Spring cotter pins are self-fastening and are mainly used to secure shafts and bolts. The easy assembly permitted by the large lug is a great advantage here. As a result, the reusable spring cotter pins are also suitable as temporary fastenings. The standard dimensions cover the sizes 1.5 to 8 and are available in steel and stainless steel.

Eye Bolts

Eye bolts in accordance with DIN 444 are traditional linking elements and are very often, used as design elements in the mechanical engineering field. The large eye in the head of the bolt is made for attaching hooks, shackles, bolts and rods or can be used as a guide element for ropes and cables. What is more, eye bolts are ideally suited for use as turnbuckles. Eye bolts offer a versatile range of connection options and the relatively long thread means that they can be assembled quickly and securely at the required position.The standard sizes in accordance with DIN 444 form B cover the connecting threads M5 to M24. Variants are available in steel, galvanized steel and stainless steel.

Axial Joints

Axial joints with specifications similar to DIN 71802 and which are both dismountable and equipped with a sealing cap are specially designed for problematic environmental conditions (dust, lubricants etc.). The gap between the axial ball socket and the ball stud is covered and sealed by a sealing cap. This provides ideal protection against serious damage due to environmental influences. The sealing caps are made of chloroprene and can be used in the temperature range from -30 °C to +110 °C (temporarily to +140 °C).

De plus, les boulons à œil sont parfaitement adaptés pour être utilisés comme tendeurs.