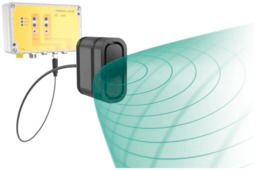

Using the 2D laser scanner, the R2000 from Pepperl+Fuchs can detect protruding objects close to the surface, and can also detect moving objects thanks to the high scan rate. When hung upside down, millimeters from the ground, the scanner has no problems detecting the tiniest of deviations. The scanner measuring module is not stationary - instead, it rotates around its own axis. In addition to providing a continuous all-round 360° view, the rotating measuring head ensures that the entire scanner has a compact design. As a result, the optical face - positioned just below the edge of the housing - allows the device to be installed directly above the surface of the area being monitored. The easily visible measuring beam enables the scanner to be aligned without the need for any additional aids, thereby making eye-protection for laser class 1 unnecessary. The measuring method utilizes pulse ranging technology (PRT): real-time pulse ranging measurements that are synonymous with low response times and a high level of immunity to extraneous light. The high scan rate of 3000 revolutions per minute and the 250,000 individual measurements per second allow highly accurate measurements.

The measuring optics of the product are not based on lens optics, but on mirror optics. Beam deflection, usually the result of mirror mechanics, is no longer necessary and any subsequent inaccuracies are thereby completely avoided. These characteristics enable light spot imaging that is identical across the entire measuring angle and a completely flat scanning surface. The light spot geometry is designed such that the diameter is not exceeded by a few millimeters even at greater distances. As a result, it is possible to install the scanner just slightly above the surface of the object being inspected, allowing structures smaller than one millimeter to be detected.

Another highlight is the integrated, interactive all-round display. By rotating the measuring module and the 24 LEDs on the back of the module, the display is able to show text and graphic messages. Having this kind of display allows the module to be commissioned using a PC or laptop. Operating and diagnostic information can be issued directly via the display during operation.