Aucotec will be the first CAE provider to show how consistently connecting the engineering system when configuring predictive maintenance (PdM) solutions greatly reduces the work involved and errors. Aucotec's database-driven software Engineering Base (EB) can be used for this purpose as a central source which provides both the PdM and the control system in parallel with all relevant data.

Manually "feeding" big data?

PdM systems are big data applications that calculate optimised maintenance intervals from the analysis of the huge amounts of live plant data sent continually by the control system or identify an impending breakdown in advance. The correct interpretation of the measured status data is required for the analysis.

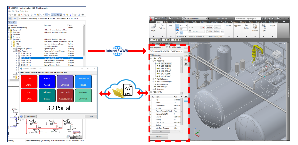

For this purpose, the PdM system must first understand, however, that the value x to signal y indicates, for example, a certain pressure on a certain sensor and not a temperature. Aucotec's solution enables the PdM to obtain this knowledge directly from the software platform EB. The engineering information previously had to be read manually into the PdM or via various interfaces and lists that had to be compiled laboriously.

This signifies a mammoth task for often 50,000 or more control system signals, even without the usual plant changes in operation.