Change is taking place wherever you look, and Industry 4.0 is just one of the reasons. The hot topic, even for end-users, is the discussion regarding current and upcoming upheaval in the automotive sector. There is, alongside the familiar issues of emissions, electromobility or driverless cars, a more-obscure area that nevertheless stands to benefit from this fundamental shift: the development of on-board power-supply systems.

Miles of wires

It is a special aspect of vehicle manufacture, whose complexity – unlike that of engines and motors – is set to increase considerably. Invisible, and no argument for car salespeople, it is however indispensable. It is the network of wiring installed in vehicles of all types, and it has grown enormously in recent years. Earlier cars used to need just a few yards of wire to connect the lights, wipers and heater, but their modern counterparts now come with thousands of individual wires, with a collective length measured in miles. In fact, the most complex part of a modern vehicle is its wiring harness, as the wider use of sensors, digital features, actuators and networking account for the use of more and more copper.

Thoroughly consistent

Quantity or quality? The quantity alone is a major headache for designers, along with the massive and diverse range of other factors involved. The key features of “quality” despite “quantity” include the end-to-end consistency of data, without breaks in the system, from the initial wiring diagram and 3D rendering of the harness right up to the complete system layout and production documentation. This consistency guarantees both speed and quality. All errors and defects cost money, and the later they are detected, the greater that cost will be.

Aucotec AG, a software developer with more than 30 years’ experience, has come up with a data-centred engineering solution designed to deal with all these challenges. It has now been more than ten years since work started on a special “cable” version of Engineering Base (EB) adapted for use in the automotive sector, and it has been steadily developed since then in cooperation with the world’s main car manufacturers.

“The decisive factor is the ability of the platform, thanks to a common data model for all involved and across all phases of the process, to ensure extraordinarily efficient and consistent multi-user operation. EB also offers special functions as part of its unique change-management capability”, explains Georg Hiebl, product manager at Aucotec’s Mobility Division. The platform is likewise able, with its wide range of variants and options, to handle the massive variety of individual vehicle configurations in a comparatively clearer manner.

Distribute the work; centralise the changes

One of the results of this extraordinary consistency is that changes carried out in one place are immediately applied to all representations of the modified item. A system of change management developed in-house also helps to provide a properly reliable overview. Whether they are interdisciplinary or the result of interaction with external suppliers, changes are easy to trace and update via the individually configurable tracking functions. This would not be possible with document-based tools. Even digital documents are often just computer-assisted lists or graphics, without any logic or detailed information behind them. This is Mr Hiebl’s take on WYSIWYG (“what you see is what you get”) with regard to conventional documents:

“What you see is, in this case, unfortunately all you get. There is no consistent thread running through the engineering process as a whole.”

When “one-off” means just that

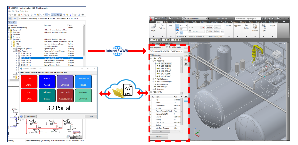

Another reason for the platform’s achievable consistency lies in its minimising of breaks in the system. Once data have been generated in EB, they can be used as a basis for the next step. They can be recycled and reused, with the gradual addition of detail, including in parallel and in different areas. This does away with error-prone transfers and the need for interface maintenance. No information is lost, and individual recipients in the various disciplines involved do not need to wait around for the arrival of data transfers. This also applies to third-party systems like ERP or 3D. Bidirectional links ensure the consistent exchange of data, without the various specialists concerned having to leave "their" system.

The integrated planning process of EB begins with the automated transfer of connection data and, if required, their rendering as a system diagram. This is the starting point for a detailed definition of the wiring system and its corresponding splices. The incorporation of 3D then opens the last door to full integration, right up to production. The interaction between 2D and 3D supplies one side with electrical and logical information, while the other receives mechanical data regarding such factors as topology and lengths. Smart delta management ensures that both disciplines are suitably adapted whenever changes take place.

“All steps in the process are based on the smart, extendible model data held on EB”, explains product manager Hiebl. They contain not only the usual sets of attributes, but also information on relationships, such as those between plug connectors and components.

Digital twins replace prototypes

The end-to-end consistency of this digital rendering, in a centralised model, of harnesses gives rise to the so-called “digital twin”. This allows international teams based in different countries to carry out efficient development work at the same time, while letting them analyse the planned functions using any vehicle configuration. EB also gives users an overview, from a central monitoring point, of the individual development-related aspects of different wiring-harness suppliers. The laborious construction of prototype vehicles can therefore be replaced with digital models, to which functional improvements can be directly applied. The ability of Aucotec’s platform to generate this digital clone of the physical harness is only possible because all the steps in the process are integrated into a common database.

“This data-centred approach is vital for ensuring that we can tackle complexity and time pressure in the development of the latest – and also future – cable harnesses for vehicles.” Mr Hiebl adds. According to him, given the scalability of EB, from individual workstation right up to global enterprise solution, and its simple integration with even highly complex existing IT systems, the changeover to a data-centred approach and the resulting digital twin amounts to a “hidden champion”.