With SmartBridge from Pepperl+Fuchs, the benefits of commercially available mobile devices are being utilized for the commissioning, parameterization, diagnostics, maintenance, and servicing of industrial sensors without any time-consuming wiring or installation work proving necessary.

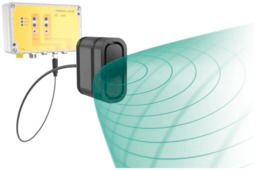

The SmartBridge adapter is looped into the sensor supply cable and supplied with energy from there. In parallel with the IO-Link communication with the controller, a wireless connection is established to mobile devices.

With the intuitive SmartBridge app, commercially available smartphones and tablet PCs (Android and iOS) become convenient operating and display devices for industrial sensors. They can then be used during commissioning and servicing of industrial sensors without time-consuming installation work or intervention in the control software.

Depending on the type of application, the adapters can be inserted into the sensor supply cabling as a temporary or permanent retrofit and, in addition to the IO-Link interface to the sensor and the Bluetooth module, also contain a memory card. This memory card can record sensor data over longer periods. The adapters also contain a USB interface for reading out recorded data.

With SmartBridge, modern tablet PCs and smartphones become clear mobile operating and display units with a wide range of applications:

- Adjusting parameters, reading and writing back settings ("digital screwdriver")

- Displaying measured values, also for sensors with digital data transfer ("intelligent multimeter")

- Recording measuring and diagnostic data for longer periods of time

Additional options unfold when the mobile device can be connected to the Internet via WLAN or a telecommunications standard such as GSM/UMTS/LTE. This creates a bridge from the sensor to the Internet, allowing the use of all services offered on the Internet.