"The Mars rovers are incredibly resilient, considering the extreme environment the hardware experiences every day", said John Callas, Project Manger at Jet Propulsion Laboratory (JPL), the NASA agency responsible for the mission. Together Spirit and Opportunity have driven more than 21 kilometres, climbed mountains, descended into craters and struggled through sand dunes.

The success of the mission surpassed all expectations: the American Space Agency NASA originally expected these robots to be operational for just three months. But even after five years, the six-wheeled vehicles are still travelling around Mars and relaying exciting data back to Earth - so far, 36 gigabytes across distances of between fifty and four hundred million kilometres, depending on the position of the planets. Spirit landed in Gusev Crater on 4 January 2004 (CET). Scientists chose this landing site south of Mars' equator because they suspected a lake used to be located there. The aim of the mission was to prove that there used to be liquid water on Mars. Three weeks later, the twin craft, Opportunity, landed on Meridiani Planum on the opposite side of the planet.

The two rovers which are both 1.6 metres long and 1.5 metres high were not only equipped with cameras, but also two spectrometers and a microscope for geological investigations.

In March 2004 NASA first reported on rock formations that were believed to have been formed by water. Today it is assumed that there was once liquid water on the surface of Mars during a long period of time.

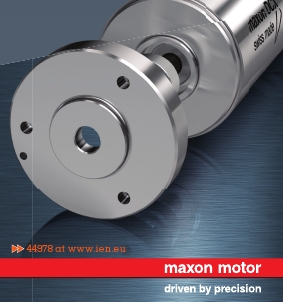

Each rover is equipped with 39 DC motors from the Swiss drive specialist maxon motor. The precision drives are used for driving the robotic arms, rock drilling, operating the cameras, the steering mechanism, and for the 6 wheels that drive the heavy vehicles (each weighing nearly 180kg) over the planet's surface.

The motors themselves are standard products with diameters of 20 and 25mm that deliver an efficiency level of more than 90%. Minor modifications were required to enable them to cope with the harsh conditions. The equipment has to be able to withstand temperature changes on the surface of Mars, which can range from around -120 to 25°C, vibrations and the special atmosphere.

The European Space Agency ESA will also be sending a rover to Mars in 2016 to search for signs of life. maxon motors will ensure that they have the right drives.