Specialty-machine constructors need competent partners in the supplier industry in order to satisfy their Principal in matters regarding safety, high quality and lifetime duration. For more than 10 years, GRAF automation GmbH from Ravensburg has had positive experience with the ACE company in the most varied areas of braking and damping technology. Cooperation involving new-value clamping elements fits seamlessly into this tradition.

"Whether it involves small shock absorbers, industrial gas springs or SLAB mats, the products from ACE have always provided us with 100 percent satisfaction. And not only that: the personal support and consultation, as well as the supply times of the company from Langenfeld, have always been an exemplary feature in our long-standing partnership" according to Eberhard Graf, general manager of GRAF automation GmbH. Specializing in complete solutions in the specialist mechanical engineering sector, his team has regularly relied on products from ACE since 1998 as reliable machine elements, which fit into the overall concept of high-quality and long-lived, compact, innovative and also price-competitive construction. To date Graf has had good experience with ACE in cylindrical grinders, tool organizers, chain and robot systems. "In every case where it is necessary to protect high-quality constructions through the most varied damping solutions, or to make them capable of use in even more powerful processes, the solutions presented to me from ACE can be easily integrated." Lothar Jungnitz, design engineer at GRAF automation GmbH, is always interested in innovative proposals in order to offer the customer new perspectives and/or to further develop their existing systems. Because of their own competitive capacity alone, Graf and Jungnitz are always assured of the most up-to-date status with the innovations of their suppliers. The so-called LOCKED elements from ACE were noticeable features in this case. They inquired of their marketing partner whether these clamping and braking elements were also suited for a clamping unit, where a small-scale and fine construction forge was designed for a customer. They could imagine using them as a variable limit stop in a jointing procedure involved in the production of drilling tools.

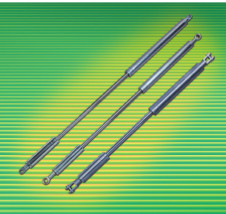

Since the clamping element on a bar should be used, it was clear from the beginning that the Series P from the ACE-LOCKED family of the Langenfeld company exclusively was suitable. This is because, unlike other model versions (see below), this is designed especially for such an employment. The specification of Jungnitz was as follows: The clamping elements should correspond ideally to the requirements of the customer for precise positioning of the workpiece head, and for equalizing of the length tolerance up to 3 mm.

In fact, after successful tests, a clamping element of the Type PN125-40-3-6B is now employed with the clamping unit in order to precisely clamp the bolts guided into the unit and extended as a limit stop, and thus successfully take up the counter forces occurring with the jointing procedure.

If so, then so, in Ravensburg: Strongest clamping element in employment

Because of the required precision and reproducible positioning of the tool and the high forces generally involved with the system from Ravensburg, the two partners agreed on using the strongest of all the possible versions of clamping elements available from ACE. The PN125-40-3-6B element is able to apply forces of up to 27,000 N. The reasons for this are diverse: As well as the largest bar and cylinder nominal diameters available in the standard tariff variants, this is due in particular to the fact that work is implemented with an opening pressure of 6 bar and the maximum number of three clamping elements. The construction team in Eberhard Graf profits here from the well-designed modular system, which ACE has also offered for clamping elements for the past four years. In this way, design engineers are capable of stacking several segments simultaneously, so that the necessary clamping force can be scaled for every application. The pneumatic clamping is effective in both directions in this case, and can also be appropriately employed as an emergency stopper, since the failure of the pneumatics provides for instant clamping of the system. Furthermore, customers such as GRAF automation GmbH profit from the compact design implementation of the overall construction. Thus integration into existing solutions, as well as the employment of short bar lengths, are simultaneously possible.

How does the pneumatic bar clamping function?

Due to the versatility of this product model, an explanation of the functioning method appears in order. Especially as this behaves in a very similar way to the models also available for clamping along railroads, rails or axes. In the clamped status, the clamping force of a mechanically pre-stressed spring-steel sheet system is introduced into the clamp socket as a retention force. The bar or shaft is clamped as a result of this. In order to release it again, a membrane, with compressed air applied, relieves the spring steel sheet systems. The clamp socket again releases the bar or shaft. If the P-Series is provided as an emergency system, a shut-off valve is activated through the force of the load due to gravity. The clamping can be then be released only by a deactivation of the shut-off valve. This occurs exclusively with the lifting of the load. In this way, these solutions represent an independent safety system for the respective application.

If clamping elements are required for rails, then the l-Series from ACE is used. The R-Series of the company offers the highest forces and retention moments for the clamping of rotary motions directly on the drive shaft. As a special feature, the chamber is surrounded by two ring-shaped membranes in this case, curved outwards and (similar to the agents of the P-Series) effect the release of the blocked element. The reset force of the membranes during the venting is implemented from the spring-loaded unit, and guarantees the required clamping without additional energy. These types of solutions provide for cost and energy savings, as well as high-performance. Thus, with the clamping elements, ACE also makes a contribution to convenience, high quality, safety and cost-effectiveness in the automation sector. Or as expressed by Eberhard Graf: "Our high demands on ACE have not been disappointed, also in case of the clamping elements."