For half a century now, the Rittmeyers in Münster (Germany) have been milling, turning and grinding for applications in the precision mechanics sector. The company has long been a family-run firm which started out as a one-man business. It specialises in the development of standard and custom machines used in for example the medical engineering sector, and the automotive and aeronautical industries. One typical attribute of the work carried out in the Münsterland is the close link between engineering and precision mechanics. And this also includes close collaboration with recipient companies.

The same approach is adapted by one of the suppliers to this company, ACE Stoßdämpfer GmbH in Langenfeld, in working with its partners. Coupled with the quality standard of the leading global supplier of industrial shock absorbers, there are two reasons behind the cooperation between the two companies. "Whenever the issue is about effective machine lag, we count on shock absorbers from ACE. Because we wanted in addition to clamp a rail guide for our BERI.CO.CUT - V3, and ACE were supplying products for this application, the company from Langenfeld was our first and only port of call", explains company boss Walter Rittmeyer.

End position protection with ACE small format shock absorbers

The third generation of the successful custom machine is responsible for the simple, precision cutting of shielding and braiding of high-voltage cables - used for example in electric and hybrid vehicles. The entire head of the machine moves when cables are worked on. As is the case with earlier machines, the Münster-based company counts on a small format ACE shock absorber for reliable braking in moving the head against the rear panel. This ensures the impact is gentle, thereby preventing costly damage to machining head and the overall structure, not to mention financial loss and loss of reputation caused by downtimes at Rittmeyer customers.

The trusting relationship between the two companies meant test systems were sacrificed and instead ACE started immediately with implementation. After consideration of all specifications, such as the moving mass and its speed, the shock absorber specialists from Langenfeld opted to fit the small format MC75EUM-3 shock absorber. These hydraulic machine elements are maintenance-free and ready to install, and have very short overall lengths and low restoring forces. The material of the shock absorber body is made of black-finished or Tenifer-annealed steel, and in combination with a temperature-stable oil filling and integrated, fixed stopper features a prolonged service live - something which certainly satisfies the requirements of a continual loading application such as a cable cutting machine.

The selected self-adjusting elements of the small format shock absorber family are able to take up 9 Nm/stroke and 28,200 Nm/h. The permissible mass range is 2.7 kg to 36.2 kg, and applies for a temperature range from 0°C to 66°C. If the requirement is to use the machine elements outside, ACE also has variants which are even resistant to sea water and other aggressive materials. In both cases, the absorbers are easy to integrate into existing equipment thanks to a number of accessories and adapters. The new design meant this scenario did not arise in Münster, although the low net weight of just 30 grams was a positive secondary effect in the planning process. "We always strive to build our designs so as to be as compact as possible. The overall shock absorber length of just 70 mm of course plays into our hands", states Walter Rittmeyer. The reset time of 0.3 seconds was also more than adequate for the cable cutting machine.

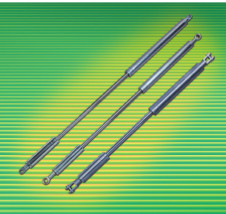

LOCKED clamping elements with different functions

In addition to the shock absorbers, LOCKED clamping elements from ACE are also deployed at Rittmeyer. These are from the PN family, designed for pneumatic clamping. They are responsible for preventing damage caused by operators not cutting cables cleanly, and for preventing damage to the machine itself. To understand why, the function of the equipment is explained briefly. The tool in the BERI.CO.CUT - V3 is moved concentrically along two guide shafts. The LOCKED elements clamp during normal operation of the pneumatics and when the pressure drops.

Preventing movement during the cutting process is a requirement during normal operation. This is because even the slightest of inaccuracies can cause the passengers of aircraft and electric vehicles to come to grief. For this reason, absolute precision of the lock process regardless of the length of the respective workpiece is of key importance. This is guaranteed by the clamping elements used (PN-63-20-2-6B) by building up a high axial pressure.

Their work is also rudimentary when a fault occurs because when the controller or compressed air supply fails, the entire tool could retreat backwards if not clamped. "In the worst case, our customers would be looking at uncontrolled movement having the effect of about one ton of force", explains Rittmeyer designer Mikhail Korontsevich. Specifically, this means the clamping elements provide assistance to the small format shock absorbers in an emergency, and so in combination prevent the worst from happening.

The LOCKED models used have a retention force of 2,520 N and 3,600 N at 4 and 6 bar respectively. ACE even supplies models which can master up to 27,000 N. The P series boasts a compact design, and for it the Langenfeld company recommends factoring in a safety margin of 10% because the retention forces specified apply for optimal conditions. And when all of the details have been taken into consideration, adverse conditions in particular should not mean perfect functioning of the cable cutting process fails. When asked, Mikhail Korontsevich then confirmed this has yet to be the case.