Hydraulic powder presses for cutting ceramics stand still on weekends and public holidays but, like their operators and supervisors, they have to start work again punctually. This is not possible without clamping elements because the pistons in the upper and lower die plates would lower during the break period and need to be readjusted. This application case shows that conversion from hydraulic to pneumatic clamping elements makes economic sense.

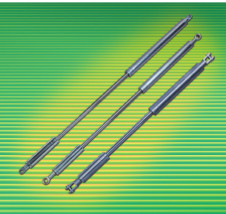

Komage Gellner AG based in Kell am See is an internationally known manufacturer of high-quality powder compacting systems. The designers of the company located in Rhineland-Palatinate were looking for a solution to prevent the unfavourable lowering of the upper and lower dies in their series S and KHA presses. Ideally, the solution would also be more cost-effective than the conventionally used hydraulic clamping elements. They asked ACE Stoßdämpfer GmbH to support them and one of our field engineers went to Kell am See to present samples that might do the job. The successful tests with the so-called PN series of our pneumatic clamping elements for rods, our service and our prices convinced Komage Gellner KG, so they said goodbye to the hydraulic clamping elements they had been using previously. The functional principle of the new ACE clamping elements now applied in the hydraulic series S and KHA presses is as simple as it is efficient: In the clamped condition, the clamping force of the mechanically pre-stressed spring steel plate system is transferred into the clamping pads. In this way, the rod or shaft is clamped. To release it again, a pneumatically pressurised membrane relieves the spring plate system and releases the clamping pads, so the rod or shaft can move freely again. The models shown in this case have retention forces of 2,000 N, so they are in the same range as the hydraulic machine elements used formerly. In other cases, they might even be replaced with more powerful elements with retention forces of up to 27,000 N.

Function 100 per cent identical, costs more than halved

As regards function, the press manufacturers were absolutely satisfied with the hydraulic clamps they had been using previously. So two things were clear from the moment they contacted ACE: Any new machine element would, firstly, have to do the job equally reliably and, secondly, be less expensive. The first requirement was demonstrated in the prototype tests and the second shortly after that, as the price of the LOCKED elements was just half that of the former ones. Additional advantages were lower system costs and easier integration into the design. In contrast to other examples of applications in which safety elements are used, it is not necessary in this case to brake the moving masses. The problem here was the lowering of the upper and lower die plates during standing time at weekends and public holidays. The presses would not be damaged without clamping elements, but they would need to be readjusted before they could be used - a time-consuming process which entails significant costs and lost production. Another advantage of the ACE products used is it's modular system allowing the stacking of several segments of the clamping elements together, so that the necessary clamping force can be individually dimensioned for each application.

Due to their consistently positive experience, Komage Gellner KG has decided to extend its cooperation with ACE. A project in which a wear bush is installed between the guiding rods and the clamping bush has already been planned. Moreover, other ACE clamping elements are being considered for further applications. As the types used in Kell am See, they are designed for up to one million cycles and fully meet all requirements which can be made on these safety elements.

The clamping element family is constantly growing

While the P series clamping elements used at Komage are intended for use with piston rods, the Langenfeld-based company has other types in store as well. All in all, a total of six series are available, e.g. for clamping linear guides and Z-axes. The family was extended in 2010 by the special series LOCKED LZ-P for clamping gravity-loaded axes and LOCKED LZ-E which for the first time provides an electrically operated retention system in which the spring assemblies are pretensioned by two miniature electric motors. The big advantage is that electricity can be the only medium used if for constructional reasons neither pneumatic nor hydraulic components are installed on the machine. In contrast to many conventional emergency stop solutions, all members of the LOCKED family can be installed directly at the moving mass as required in a particular case to brake it rapidly and safely at any point of the travel. And, as many products made by ACE, they do not depend on the power supply of the machine or plant to be protected by the emergency stop system. This also goes for the electrically operated ACE models. Accordingly, these solutions are independent safety systems for the respective application.