In the past an apprentice needed to produce a masterpiece to prove his extraordinary skills, today this usually serves to prove that he masters traditional techniques and the techniques of his craft. In a broader sense this word is used to describe something that is spectacularly successful. The Austrian Klaus Manhartsgruber created a masterpiece that satisfied all requirements when he integrated ACE rotation brakes into his TV/bar furniture.

Before taking his master carpenter examination, Klaus Manhartsgruber had an idea: he wanted his masterpiece to combine simple design with juvenile elegance and comfort. Relatively quickly he came up with the idea of constructing a TV-bar element made of two cubes. The horizontal TV part would have a hatch and two doors made of glass whilst the vertical bar part would have a wooden door and a bar hatch that could be turned by 90°. Integrated inside the bar element are various integrated Plexiglas attachments for bar and wine glasses which are illuminated with LED lights. The LED strips are attached behind the wine bottle holder. These lights switch off automatically when the bar hatch is closed, however it makes sense for the wall lighting to remain on when watching TV because it stops the eyes tiring quickly in the dark.

This integrated concept by Klaus Manhartsgruber specified that the bar hatch would be fitted with a rotation brake that he and a friend designed. This would make opening and closing much easier and would also protect the hatch from excessive forces at the end stoppers whilst also avoiding the risk of fingers becoming caught. However this development was still in its infancy and would have required time to fulfil the required function so that the future master craftsman contacted the ACE Stoßdämpfer office in Linz, Austria.

Solution partner to the furniture industry and wood designers

After describing what was needed and sending the key data, the ACE designers proposed using rotation brakes to absorb the forces exerted when opening and closing the 7 kg hatch. These small helpers are specially designed for opening and closing small hoods, compartments and drawers. The ACE machine elements used here of the type RB FYN-U1-R/L 303 have a total length of just 57 mm and a maximum diameter of 16 mm which makes them predestined for installation in the rotating wooden hatch. Owing to the fact that their movement radius is restricted, it made sense to use the above-mentioned types. These belong to the so-called limited rotation brakes, which means that their work angle is maximum 115°. There are all-round rotation brakes available from the Langenfeld production halls of the ACE damping specialist for other applications. In both cases, the machine elements bearing the type designation code "RB" are filled with silicone oil that is displaced via a throttle or a gap. The braking torque is determined by the viscosity of the liquid and the cross-section of the throttle.

The ACE staff also proposed installing the right-turning and left-turning machine elements that have a braking torque of 300 Ncm each for the customer. The harmonious gentle movement of the rotation brakes has been used many times over to upgrade the quality and value of a product, for example when integrated into the opening compartments of hi-fi devices, sinking or swivelling cockpit parts in upper class limousines or silent toilet seats and lids. Like the two-sided working counterparts, ACE supplies models with one-sided brakes that always have a certain amount of leeway below in terms of the braking force. One should not lose sight of the fact that the braking toque of the medium will decrease slightly over time. But even after 50,000 cycles, they still have 80% of their original output. Even hobby wine-tasters will be able to pass on their models to the next few generations.

Furniture industry experience a wow effect

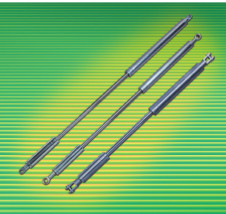

As masterpieces by young carpenters are often the source of ideas for future productions, there have been several enquiries for clever solutions using rotations brakes. In particular because a second masterpiece was created at the same time using gas springs. Using its experience, ACE was able to advise the master craftsman of this other piece of furniture to swap the gas springs for rotation brakes. As this example shows, the rotation brakes and the work by Klaus Manhartsgruber, who also passed his master carpenter examination with flying colours and now works as a furniture designer, was a real masterpiece.